If the welded pipe is stored for a long time, problems such as rust and anti-corrosion layer aging will occur, which will affect the normal use of the welded pipe. The welded pipes stored for a long time should be inspected regularly, and the exposed welded pipes should always be kept clean and stained, and stored neatly in a ventilated and dry place indoors. It is strictly forbidden to pile up in the open air or in a humid place. Always keep the welded pipe dry and ventilated, keep it clean, and store it in the correct storage method.

Read more

Carburizing is a surface heat treatment technology, which refers to the heat treatment method of quenching after expanding carburizing atoms on the surface of seamless pipes. By increasing the carbon content on the surface of the seamless pipe, the wear resistance, durability, toughness and other properties of the seamless pipe can be significantly improved.

Read more

1. The surface of inferior seamless steel pipes is prone to scarring.Mainly due to two reasons:(1) Inferior seamless steel pipes have more impurities and uneven materials.(2) The guides and guards of inferior pipe manufacturers are poorly equipped, and are particularly prone to sticking to steel. The pipes containing impurities are prone to scarring after being bitten into the rolled spokes.

Read more

The main cooling bed types of the seamless steel pipe production line are single chain cooling bed, double chain cooling bed, new chain cooling bed, stepping rack cooling bed and screw cooling bed.

Read more

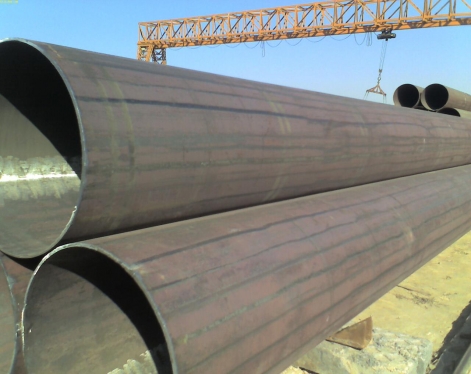

Spiral steel pipe (SSAW pipe) is a welded steel pipe with spiral weld seam, which is made of strip steel coil as raw material, extruded at regular temperature, and welded by automatic double-wire double-sided submerged arc welding process. When there are defects such as broken arc, burn through, slag inclusion, pores, cracks and other defects in the weld of the spiral steel pipe, the problem weld of the spiral steel pipe needs to be repaired, which is called repair welding.

Read more

Welded steel pipe refers to a steel pipe with seams on the surface that is welded after bending and deforming a steel strip or steel plate into a circular, square or other shape. The blanks used for welded steel pipes are steel plates or strips. With the rapid development of continuous rolling production of high-quality strip steel and the advancement of welding and inspection technology, the quality of welds has been continuously improved, and the varieties and specifications of welded steel pipes have increased day by day, and seamless steel pipes have been replaced in more and more fields.

Read more