For cold drawn seamless tubing, how to calculate how much pressure it can withstand when the outer diameter and wall thickness are known?

Read more

Tensile test is one of the important means to test the mechanical properties and material properties of cold drawn seamless tubing.

Read more

For cs seamless pipes, the three elements of solution treatment are temperature, holding time and cooling rate. The solution temperature is mainly determined according to the chemical composition.

Read more

The straightening process of the cold drawn seamless tubing determines the geometry of the cold drawn seamless tubing and also affects its mechanical properties.

Read more

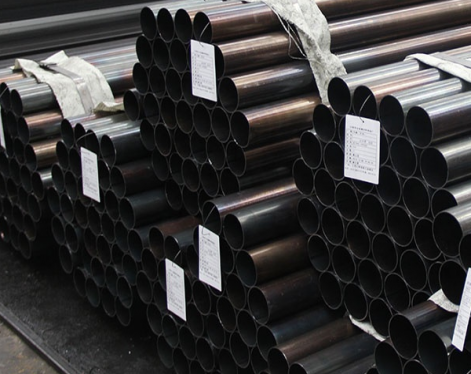

Whether the quality of black steel seamless pipe is defective is an important criterion for uating whether the quality of the product meets the standard.

Read more

Understanding the defects of cs seamless pipes and knowing how to avoid them can reduce a lot of unnecessary losses, thereby promoting the rational use of resources.

Read more