In the construction sequence of steel pipe piles, you should first grasp all aspects of the project for comprehensive consideration and analysis.

Read more

There are many ways to classify pressure vessels, from the perspective of use, manufacturing and supervisory inspection.

Read more

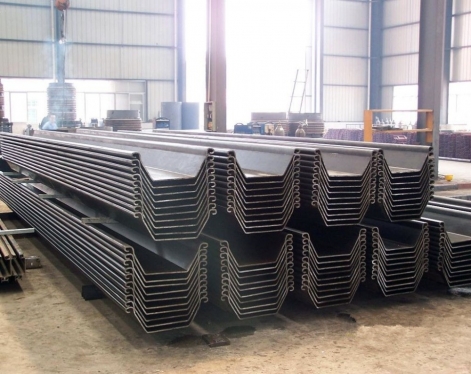

U-piles, as a new type of building decoration material, are used as soil, water and sand retaining walls when building bridges and slope protection, laying large, medium and small pipelines, and temporary ditch foundation pits.

Read more

According to the geometric shape, there are mainly four types: cylindrical container, spherical container, rectangular container, and combined container.

Read more

Because the steel pipe pile is round, the soil squeezing effect is greater than that of the steel sheet pile, and there are more process procedures, and the steel sheet pile can be directly driven in and connected.

Read more

A pipe spool refers to a section of a piping system that is prefabricated as smaller segments with flanges and fittings. Piping spools are often prone to corrosion due to their exposure to the elements, water and other natural electrolytes.

Read more