Carbon Steel Pipe

Stainless Steel Pipe

Fittings

OCTG

Steel Structure

Value-Added Products

Clad Pipe

Coated Steel Pipe

Technical Data

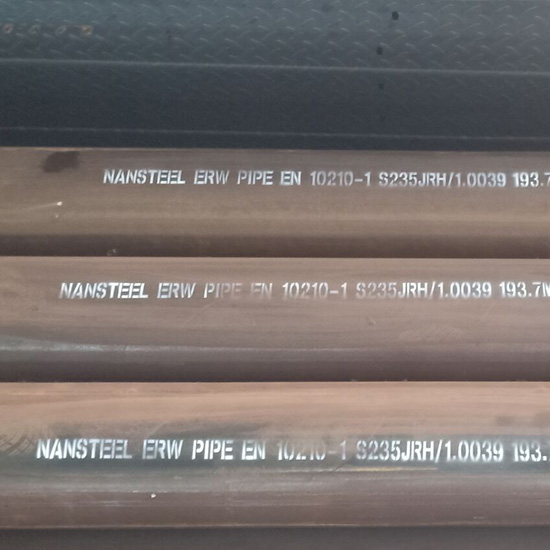

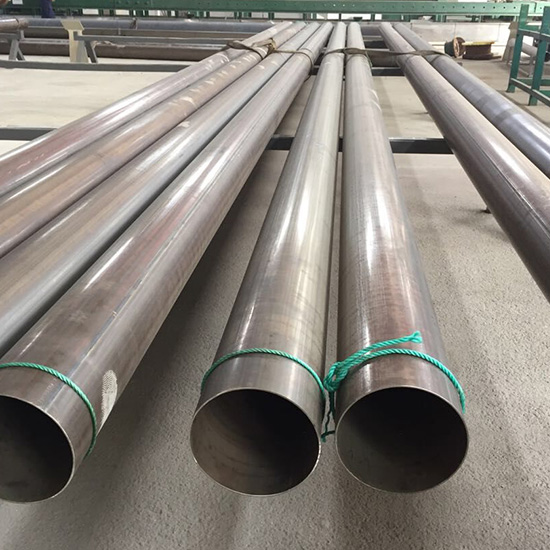

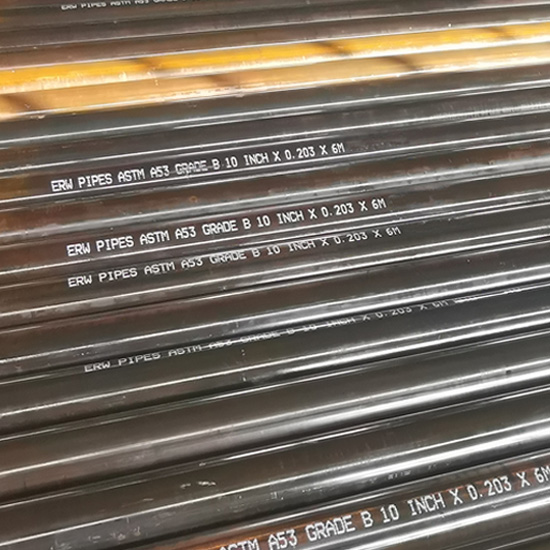

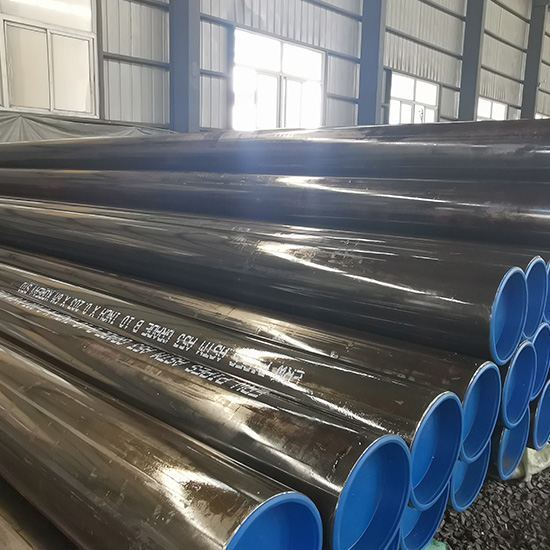

Photos

ERW steel pipes means Electric Resistance Welded Pipes.

Standards of erw steel pipe| ERW Pipe | ||

| ASTM | ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513 | |

| API | API 5L X42/46/52/56/60/70 | |

| EN | EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H | |

| EFW Pipe | ||

| Carbon steel | ASTM A671,ASTM A672 | |

| Alloy steel | ASTM A691 | |

Sizes of erw steel pipe

Out diameter: 1/2" -24" (21.3mm-610mm)

Wall thickness: 1.65mm-20mm

Manufacturing Process of ERW steel pipe

Electric Resistance Welded (ERW) pipe is manufactured by cold forming a flat steel strip into a rounded tube and passing it through a series of forming rollers to obtain a longitudinal seam. The two edges are then simultaneously heated with a high frequency current and squeezed together to form a bond. The longitudinal ERW seam does not require filler metal.

Details of production

Recieving and offloading of coil Coil feed ramp

Coil to coil end welding Strip accumulator

Rough edge conditionting of coil Fine edge conditioning of strip before welder

Breakdown and fin cold rolling stands High frequency erw welder

Annealing of weld seam for superior strength Final shape pass

In-line traveling saw Hydrostatic pressure testing and straightening

Full weld integrity inspection Beveling,cut-off and shipping

- Small diameter

| Out diameter | Sch 5 | Sch 10 | Sch 40 | ||||

| Inch | mm | Thickness | Kg/mtr | Thickness | Kg/mtr | Thickness | Kg/mtr |

| 1/2" | 21.3 | 1.65 | 0.81 | 2.11 | 1.01 | 2.77 | 1.29 |

| 3/4" | 26.7 | 1.65 | 1.03 | 2.11 | 1.30 | 2.87 | 1.71 |

| 1" | 33.4 | 1.65 | 1.31 | 2.77 | 2.12 | 3.38 | 2.54 |

| 1 1/4" | 42.2 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 1 1/2" | 48.3 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 2" | 60.3 | 1.65 | 2.42 | 2.77 | 3.98 | 4.81 | 5.31 |

| 3" | 88.9 | 2.11 | 4.58 | 3.05 | 6.54 | 5.49 | 11.45 |

| 3 1/2" | 101.6 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 4" | 114.3 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 5" | 141.3 | 2.77 | 9.50 | 3.40 | 11.74 | 6.55 | 22.10 |

| 6" | 168.3 | 2.77 | 11.47 | 3.40 | 14.04 | 7.11 | 28.68 |

| 8" | 219.1 | 2.77 | 14.99 | 3.76 | 20.25 | 8.18 | 43.16 |

Large diameter

| OD | WT | ||||||||||||||||||

| Inch | mm | 8 5/8" | 219.1mm | 10 3/4" | 273.1 mm |

12 3/4" | 325.0 mm |

14" | 355.6 mm |

16" | 406.4 mm |

18" | 457.7 mm |

20" | 508.0 mm |

24" | 610 mm |

24 4/5" | 630.0 mm |

| 0.157 | 4.0 | ---- | --- | ||||||||||||||||

| 0.197 | 5.0 | --- | --- | --- | --- | --- | --- | --- | --- | ||||||||||

| 0.236 | 6.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||||

| 0.276 | 7.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||

| 0.315 | 8.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||

| 0.354 | 9.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||

| 0.394 | 10.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 0.133 | 11.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 0.492 | 12.5 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 0.551 | 14.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||

| 0.630 | 16.0 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||

| 0.689 | 17.5 | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- | ||||||||

| 0.748 | 19.0 | --- | --- | --- | --- | --- | --- | --- | --- | ||||||||||

| 0.787 | 20.0 | --- | --- | --- | --- | --- | --- | ||||||||||||