Carbon Steel Pipe

Stainless Steel Pipe

Fittings

OCTG

Steel Structure

Value-Added Products

Clad Pipe

Coated Steel Pipe

Technical Data

Photos

Casing pipe is used for lining the complete borehole which has been dug into the ground to procure oil. Similar to the drill pipe, the oil well casing pipe is also subjected to axial tension, therefore they are required to be made from high-quality strong steel material. OCTG casing is large diameter pipe which are held in place in the borehole using cement.

The diameters of OCTG casing pipe range from 4.5″ to 36″. The well-cemented pipe acts as the structural component of the well and offer hole integrity. They prevent the well from collapsing when the drilling process is on. Good quality, well cemented casing can stay in place for the whole life of the well.

Casing pipe installation

Installation of casing pipe involves assembling series of steel pipes comprising individual joints, with varying lengths depending on the type of casing string. These joints feature male threads on each end, connected together using short sections of double-female threaded pipe known as collars or couplings. Some manufacturers offer pipe joints with pre-attached female threads on one end. Each pipe string has a decreasing diameter compared to the previous one, tapering the strings down into the wellbore.

Casing strings and drill strings alternate within the wellbore. After completing a section of drilling, the drill string is removed from the hole, a new casing string is inserted and cemented, and then the drill string is re-inserted with a smaller bit to accommodate the narrower pipe.

Once inside the wellbore, steel pipe casing strings are cemented in place around the outside diameter of the pipe. This is achieved by pumping a mixture of cement slurry and drilling mud down the casing string with a bottom plug and a top plug. The mixture flows through the casing, filling the space between the outside of the pipe and the well wall (the annular space/annulus). Following cementing of the casing pipe, drilling operations can resume.

Tubing is inserted inside the wellbore through the oil well casing pipe, which helps the transportation of the hydrocarbons to the surface. It is pipe either used for transporting natural gas or crude oil to the facilities for further processing after the drilling is complete. Similar to the drill pipe and casing, tubing also is subjected to high pressure during the extraction process, and hence needs to be thick, strong and sturdy. Production tubing is available in various sizes ranging from ¾” to 4 ½”.

Casing sizes:

Sizes: 13-3/8” thru 4-1/2” Casing

Grades: J-55, L-80, N-80, And P-110

Range: Range 1 thru Range 3

Connections: BTC, STC, LTC, NUE, EUE

Bands: White, Yellow, Blue, and Green

Tubing sizes:

Sizes: 4-1/2” thru 2-1/16”

Grades: J-55, L-80, N-80, And P-110

Range: Range 2

Connections: BTC, STC, LTC, NUE, EUE

Bands: White, Yellow, Blue, and Green

Casing Pipe Application:

|

Road Bore Casing |

Water Well Casing |

|

Culverts Casing |

Open Cut Casing |

|

Oil and Gas Transmission Pipeline Casing |

Drilling Casing – Surface Casing – Rathole Casing |

|

Tunnel Casing |

|

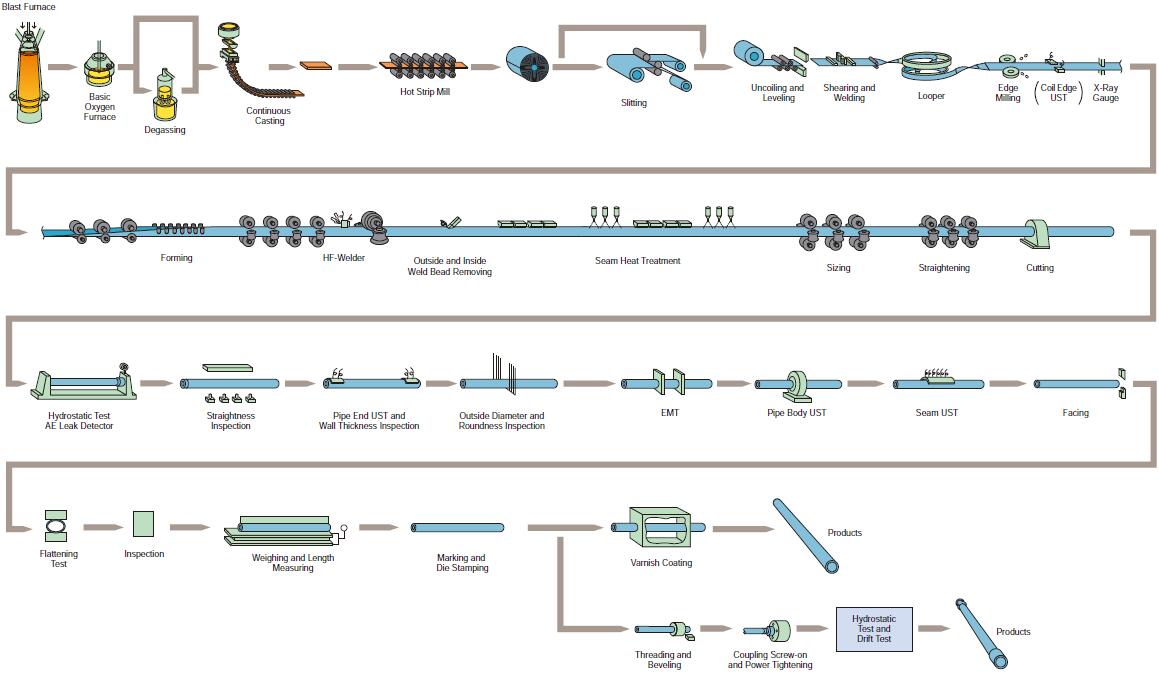

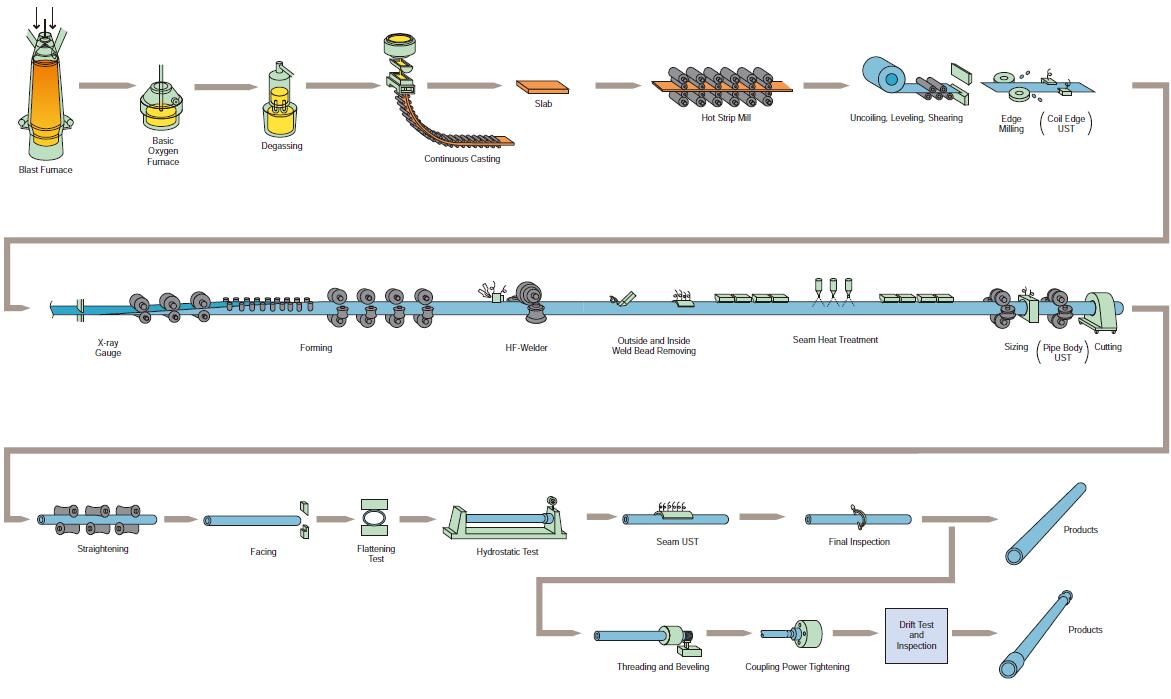

Casing Manufacturing Process

❶ Steelmaking

Degassing and desulfurizing of the metal during the steelmaking process produce clean steel with low non-metalic inclusions and better surface finish.

❷ Hot Rolling

Advanced hot rolling results in hot coil with a fine grain structure and high dimensional accuracy.

❸ Spiral Looper

The spiral looper supplies a steady feed of coil downstream to the continuous edge milling, pipe forming and welding stands.

❹ Forming Stands

Heavy duty stands accurately form the incoming coil into pipe having a wide range of wall thickness and outside diameter.

❺ HF-Welder

“Welding Condition Monitoring and Controling System”, developed by NSSMC, produces high quality welds. Seams are inspected by ultrasonic testing.

❻ Welded Seam Heat Treatment

Heat treatment in the welded zone stabilizes the microstructure and gives it the same physical properties as the base metal. The exact seam position is determined by optical sensors for seam heat treatment, and ultrasonic and hydrostatic testing.

❼ Non-destructive Testing

Every length and entire surface of each T.U.F.-Pipe is subjected to a full line-up of non-destructive tests.

❽ Automatic Inspection

Every pipe is given a comprehensive check using automatic inspection equipment.

❾ Monitoring and Tracking System

T.U.F.-Pipe is monitored and tracked at every stage of production by on-line computers. All manufacturing data is stored by computer and can be made available in any form required by the customer.

❿ Marking

Automatic stencilling and die-stamping machines identify and clearly mark every pipe.

⓫ Threading

Advanced NC lathes cut high precision threads to order. Connectors for large O.D. casings are also available. The use of thread protectors is recommended to prevent damage to the connectors during handling, loading and pipe rolling.

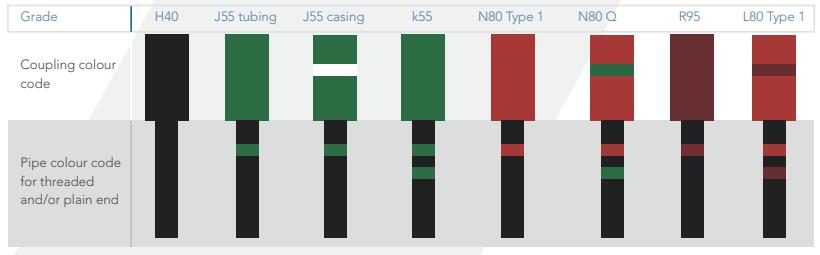

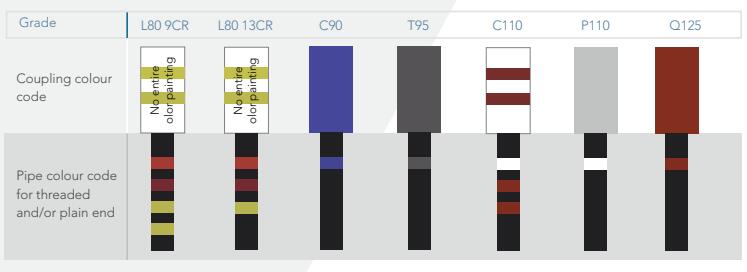

Casing Pipe Coupling colour code

Casing Pipe Chemical Composition, Mass Fraction(%):

|

|

|

C |

Mn |

Mo |

Cr |

Ni Max |

Cu Max |

P Max |

S Max |

Si Max |

||||

|

Min |

Max |

Min |

Max |

Min |

Max |

|

Max |

|||||||

|

H40 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

J55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

K55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80 |

1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80 |

Q |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

M65 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

L80 |

1 |

- |

0.43 |

- |

1.90 |

- |

- |

- |

- |

0.25 |

0.35 |

0.030 |

0.030 |

0.45 |

|

L80 |

9 Cr |

- |

0.15 |

0.30 |

0.60 |

0.90 |

1.10 |

8.00 |

10.0 |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

|

L80 |

13 Cr |

0.15 |

0.22 |

0.25 |

1.00 |

- |

- |

12.0 |

14.0 |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

|

C90 |

1 |

- |

0.35 |

- |

1.20 |

0.25 |

0.85 |

- |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

|

P110 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

Q125 |

1 |

- |

0.35 |

- |

1.35 |

- |

0.85 |

- |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

Note:If the wall thickness is less than 17.78mm, the molybdenum content of the C90-1 steel grade has no lower limit.

Dimension Tolerances:

|

Casing Pipe |

Tolerance |

|

|

Outside Diameter |

Pipe Body |

D≤101.60mm,±0.79mm |

|

D≥114.30mm,+1.0%, -0.5%D |

||

|

Coupling |

±1%D |

|

|

Wall Thickness |

0, -12.5%t |

|

|

Weight |

Single Lengths |

+6.5%,-3.5% |

|

Carload Lots or Order Quantity |

≥18144 kg(40000ib),0,-1.75% |

|

|

<18144 kg(40000ib),0,-3.5% |

||

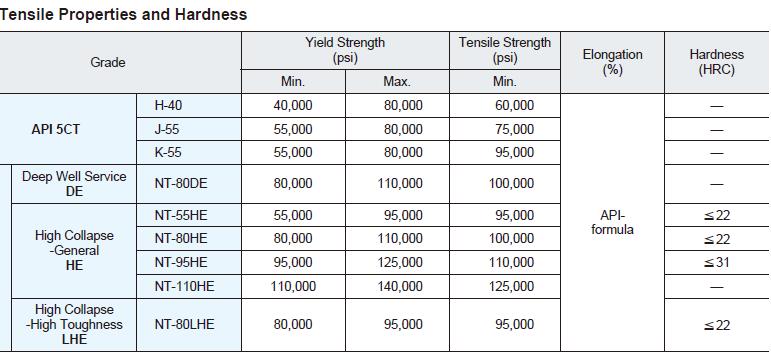

Tensile and Hardness Requirements:

|

Steel grade |

Type |

Total elongation under load (%) |

|

min |

Hardness max |

||

|

min |

max |

HRC |

HBW |

||||

|

H40 |

- |

0.5 |

276 |

552 |

414 |

- |

- |

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

M65 |

- |

0.5 |

448 |

586 |

586 |

22 |

235 |

|

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9 Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

13 Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

C90 |

1 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

|

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

- Seamless casing specification

| Outside Diameter | Nominal Weight | Wall Thickness | Grade and Connection Type* | ||||||||

| in. | mm | lb/ft | kg/m | in. | mm | J55 K55 |

M65 | L80 C95 |

N80 | C90 T95 |

P110 |

| 4-1/2 | 114.30 | 9.50 | 14.14 | 0.205 | 5.21 | PS | PS | - | - | - | - |

| 10.50 | 15.63 | 0.224 | 5.69 | PSB | PSB | - | - | - | - | ||

| 11.60 | 17.26 | 0.250 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | ||

| 13.50 | 20.09 | 0.290 | 7.37 | - | PLB | PLB | PLB | PLB | PLB | ||

| 15.10 | 22.47 | 0.337 | 8.56 | - | - | - | - | - | PLB | ||

| 5 | 127.00 | 11.50 | 17.11 | 0.220 | 5.59 | PS | PS | - | - | - | - |

| 13 | 19.35 | 0.253 | 6.43 | PSL | PSLB | - | - | - | - | ||

| 15.00 | 22.32 | 0.296 | 7.52 | PSLB | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 18.00 | 26.79 | 0.362 | 9.19 | - | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 21.40 | 31.85 | 0.437 | 11.10 | - | PLB | PLB | PLB | PLB | PLB | ||

| 23.20 | 34.53 | 0.478 | 12.14 | - | - | PLB | PLB | PLB | PLB | ||

| 24.10 | 35.86 | 0.500 | 12.70 | - | - | PLB | PLB | PLB | PLB | ||

| 5-1/2 | 139.70 | 14.00 | 20.83 | 0.244 | 6.20 | PS | PS | - | - | - | - |

| 15.50 | 23.07 | 0.275 | 6.98 | PSLB | PSLB | - | - | - | - | ||

| 17.00 | 25.30 | 0.304 | 7.72 | PSLB | PLB | PSLB | PSLB | PLB | PSLB | ||

| 20.00 | 29.76 | 0.361 | 9.17 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 23.00 | 34.23 | 0.415 | 10.54 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 6-5/8 | 168.28 | 20.00 | 29.76 | 0.288 | 7.32 | PSLB | PSLB | - | - | - | - |

| 24.00 | 35.72 | 0.352 | 8.94 | PSLB | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 28.00 | 41.67 | 0.417 | 10.59 | - | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 32.00 | 47.62 | 0.475 | 12.06 | - | - | PSLB | PSLB | PSLB | PSLB | ||

| 7 | 177.80 | 20.00 | 29.76 | 0.272 | 6.91 | PS | PS | - | - | - | - |

| 23.00 | 34.23 | 0.317 | 8.05 | PSLB | PLB | PSLB | PSLB | PLB | - | ||

| 26.00 | 38.69 | 0.362 | 9.19 | PSLB | PLB | PSLB | PSLB | PLB | PSLB | ||

| 29.00 | 43.16 | 0.408 | 10.36 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 32.00 | 47.62 | 0.453 | 11.51 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 35.00 | 52.13 | 0.498 | 12.65 | - | - | PSLB | PSLB | PLB | PSLB | ||

| 38.00 | 56.60 | 0.540 | 13.72 | - | - | PSLB | PSLB | PLB | PSLB | ||

| 7-5/8 | 193.68 | 26.40 | 39.29 | 0.328 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | - |

| 29.70 | 44.20 | 0.375 | 9.52 | - | PLB | PLB | PLB | PLB | PLB | ||

| 33.70 | 50.15 | 0.430 | 10.92 | - | PLB | PLB | PLB | PLB | PLB | ||

| 39.00 | 58.05 | 0.500 | 12.70 | - | - | PLB | PLB | PLB | PLB | ||

| 42.80 | 63.69 | 0.562 | 14.27 | - | - | PLB | PLB | PLB | PLB | ||

| 45.30 | 67.41 | 0.595 | 15.11 | - | - | PLB | PLB | PLB | PLB | ||

| 47.10 | 70.09 | 0.625 | 15.88 | - | - | PLB | PLB | PLB | PLB | ||

| 8-5/8 | 219.08 | 24.00 | 36.75 | 0.264 | 6.71 | PS | PS | - | - | - | - |

| 28.00 | 41.67 | 0.304 | 7.72 | - | PS | - | - | - | - | ||

| 32.00 | 47.66 | 0.352 | 8.94 | PSLB | PSLB | - | - | - | - | ||

| 36.00 | 53.62 | 0.400 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | - | ||

| 40.00 | 59.58 | 0.450 | 11.43 | - | PLB | PLB | PLB | PLB | PLB | ||

| 44.00 | 65.54 | 0.500 | 12.70 | - | - | PLB | PLB | PLB | PLB | ||

| 49.00 | 72.99 | 0.557 | 14.15 | - | - | PLB | PLB | PLB | PLB | ||

| 9-5/8 | 244.48 | 36.00 | 53.57 | 0.352 | 8.94 | PSLB | PSLB | - | - | - | - |

| 40.00 | 59.53 | 0.395 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | - | ||

| 43.50 | 64.73 | 0.435 | 11.05 | - | PLB | PLB | PLB | PLB | PLB | ||

| 47.00 | 69.94 | 0.472 | 11.99 | - | PLB | PLB | PLB | PLB | PLB | ||

| 53.50 | 79.62 | 0.545 | 13.84 | - | - | PLB | PLB | PLB | PLB | ||

| 58.40 | 86.91 | 0.595 | 15.11 | - | - | PLB | PLB | PLB | PLB | ||

| 10-3/4 | 273.05 | 40.50 | 60.32 | 0.350 | 8.89 | PSB | PSB | PLB | PLB | PLB | PLB |

| 45.50 | 67.78 | 0.400 | 10.16 | PSB | PSB | - | - | - | - | ||

| 51.00 | 75.96 | 0.450 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | ||

| 55.50 | 72.67 | 0.495 | 12.57 | - | PSB | PSB | PSB | PSB | PSB | ||

| 60.70 | 90.41 | 0.545 | 13.84 | - | - | - | - | PSB | PSB | ||

| 65.70 | 97.86 | 0.595 | 15.11 | - | - | - | - | PSB | PSB | ||

| 13-3/8 | 339.70 | 54.50 | 81.18 | 0.380 | 9.65 | PSB | PSB | - | - | PSB | PSB |

| 61.00 | 90.86 | 0.430 | 10.92 | PSB | PSB | - | - | - | - | ||

| 68.00 | 101.29 | 0.480 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | ||

| 72.00 | 107.24 | 0.514 | 13.06 | - | - | - | - | PSB | PSB | ||

| 20 | 508.00 | 94.00 | 139.89 | 0.438 | 11.13 | SLB | SLB | - | - | - | - |

| 106.50 | 158.49 | 0.500 | 12.70 | SLB | SLB | - | - | - | - | ||

| 133.00 | 197.93 | 0.635 | 16.13 | SLB | - | - | - | - | - | ||

ERW casing specification

| Outside Diameter | Nominal Weight | Wall Thickness | Grade | Connection Type* | |||

| in. | mm | lb/ft | kg/m | in. | mm | ||

| 5-1/2 | 139.70 | 14.00 | 20.83 | 0.244 | 6.20 | J55/K55 | PS |

| 15.50 | 23.07 | 0.275 | 6.98 | J55/K55 | PSLB | ||

| 17.00 | 25.30 | 0.304 | 7.72 | J55/K55 | PSLB | ||

| 6-5/8 | 168.28 | 24.00 | 35.72 | 0.352 | 8.94 | J55/K55 | PSLB |

| 7 | 177.80 | 20.00 | 29.76 | 0.272 | 6.91 | J55/K55 | PS |

| 23.00 | 34.23 | 0.317 | 8.05 | J55/K55 | PSLB | ||

| 26.00 | 38.69 | 0.362 | 9.19 | J55/K55 | PSLB | ||

| 8-5/8 | 219.08 | 24.00 | 35.75 | 0.264 | 6.71 | J55/K55 | PS |

| 28.00 | 41.67 | 0.304 | 7.72 | J55/K55 | PS | ||

| 32.00 | 47.66 | 0.352 | 8.94 | J55/K55 | PSLB | ||

| 36.00 | 53.62 | 0.400 | 10.16 | J55/K55 | PSLB | ||

| 9-5/8 | 244.48 | 36.00 | 53.57 | 0.352 | 8.94 | J55/K55 | PSLB |

| 40.00 | 59.53 | 0.395 | 10.03 | J55/K55 | PSLB | ||

| 10-3/4 | 273.05 | 40.50 | 60.32 | 0.350 | 8.89 | J55/K55 | PSB |

| 45.50 | 67.78 | 0.400 | 10.16 | J55/K55 | PSB | ||

| 13-3/8 | 339.70 | 48.00 | 71.43 | 0.330 | 8.38 | J55/K55 | PSB |

| 54.50 | 81.18 | 0.380 | 9.65 | J55/K55 | PSB | ||

| 61.00 | 90.86 | 0.430 | 10.92 | J55/K55 | PSB | ||

| 68.00 | 101.29 | 0.480 | 12.19 | J55/K55 | PSB | ||

Tubing specification

| Outside Diameter | Wall Thickness | Weight | Grade and Upset Type* | |||||||||

| Non-Upset T&C | External Upset T&C | |||||||||||

| in. | mm | in. | mm | lb/ft | kg/m | lb/ft | kg/m | J55 | L80 | N80 | C90 | P110 |

| 2-3/8 | 60.32 | 0.167 | 4.24 | 4.00 | 5.95 | - | - | PN | PN | PN | PN | - |

| 0.190 | 4.83 | 4.60 | 6.85 | 4.70 | 6.99 | PNU | PNU | PNU | PNU | PNU | ||

| 0.254 | 6.45 | 5.80 | 8.63 | 5.95 | 8.85 | - | PNU | PNU | PNU | PNU | ||

| 0.336 | 8.53 | 7.35 | 10.94 | 7.45 | 11.09 | PU | - | PU | PU | - | ||

| 2-7/8 | 73.02 | 0.217 | 5.51 | 6.40 | 9.52 | 6.50 | 9.67 | PNU | PNU | PNU | PNU | PNU |

| 0.276 | 7.01 | 7.80 | 11.61 | 7.90 | 11.76 | - | PNU | PNU | PNU | PNU | ||

| 0.308 | 7.82 | 8.60 | 12.80 | 8.70 | 12.95 | - | PNU | PNU | PNU | PNU | ||

| 0.340 | 8.64 | 9.35 | 13.91 | 9.45 | 14.06 | - | PU | - | PU | - | ||

| 0.440 | 11.18 | 11.50 | 17.11 | - | - | N | PN | - | PN | - | ||

| 3-1/2 | 88.90 | 0.216 | 5.49 | 7.70 | 11.46 | - | - | PN | PN | PN | PN | - |

| 0.254 | 6.45 | 9.20 | 13.69 | 9.30 | 13.84 | PNU | PNU | PNU | PNU | PNU | ||

| 0.289 | 7.34 | 10.20 | 15.19 | - | - | PN | PN | PN | PN | - | ||

| 0.375 | 9.52 | 12.70 | 18.91 | 12.95 | 19.27 | - | PNU | PNU | PNU | PNU | ||

| 4 | 101.60 | 0.226 | 5.74 | 9.50 | 14.14 | - | - | PN | PN | PN | PN | - |

| 0.262 | 6.65 | - | - | 11.00 | 16.37 | PU | PU | PU | PU | - | ||

| 4-1/2 | 114.30 | 0.271 | 6.88 | 12.60 | 18.75 | 12.75 | 18.97 | PNU | PNU | PNU | PNU | - |

|

* Premium connections are available on request. P - plain end, N - non-upset, E - external upset. |

- Saudi Arabia

23# 5.5" P110, 300 000ft, Carbon steel, no upset connection, 10 000# burst 3000 pcs

45.5# 10.75", 80ksi, 300 000ft, Carbon steel, no upset connection, 10 000# burst 1500 pcs

32# 8 5/8", 80ksi, 300 000ft, Carbon steel, no upset connection, 10 000# burst 1000 pcs

Seamless casing tube without threaded and taper 273/260 mm x 3.0m

i)O.D: 273mm

ii) I.D: 260mm

iii)Wall thickness: 6.3mm minimum

iv)Suitable for ODEX drilling 240W-G2

v) Standard API 5CT

vi)Connection of casing tube should be male and female type for smooth welding

Nigeria

API 5CT K55 PSL 1, Connection: BTC, Size:18 5/8”, Weight ppf: 87.5, OD(mm): 473.08, WT(mm): 11.05, Length(mtr): 10.36.11.8 Theoretical Weight (kg)/meter): 134.21, Quantity CBM/M3: 134.28, Weight/Ton: 78.13, Meters: 6000

API 5CT K55 PSL 1, Connection: BTC, Size:18 5/8”, Weight ppf: 87.5, OD(mm): 473.08, WT(mm): 11.05 Length(mtr): 6.000 Theoretical Weight (kg)/meter): 2.69, Quantity CBM/M3: 134.28, Weight/Ton: 78.13, Meters: 12000

Approximate length of 10000m

Wire-warped screen type: pipe based

Base pipe: Seamless carbon steel casing; OD 9 5/8” Wt 36 Lb/ft Grade K-55

Perforation & pipe ends: 16mm diameter of hole (min. 16% open area) BTC acc to API 5B with pin &box thread protectors incl. safety ring (installed between screen jacket and base pipe)

Screen jacket (with V-shape wire) : Grade AISI 304L, slot opening 0.015” ( +/- 0.002”), profile wire size 2.1*2.4mm, support rod 2.1*2.4mm, overall length 5.300 – 5.800 mm including both pin&box but excluding thread protector (+0mm/-50mm) Effective screen length 4.300-4.800(+/-mm)

Approximate length of 30000m

10 3/4 ” Casing ERW Carbon steel casing ASTM/API 5L Grade B bevelled end mills standard varnish length approximate 12m OD 273.1mm with end protector MTC as per EN 7.09 WT

Approximate length of 4000m

14" O.D. H48 lb/ft, Range II API Standard 5CT or 5L Casing , bevelled end casing.made of carbon steel by ERW process .The pipe itself shall be black coated with paint.The length of each pipe should not exceed 10 m. ASTM standard is acceptable

Irap

Pipe Diameter φ88.9mm, wall thickness 10.92 mm, length 12m, Steel grade:N80 yield strength Fy ≥550Mpa; Qty - 1075 nos

United Arab Emirates

Seamless API Pipe Casing ( 9-5/8" ) 36 LBS/FT J55 Thread BTC Length R3

Casing 9-5/8" L80-1 / 11.99mm 47ppf BTC length 9.5-12.0m

Casing 7" L80-1 / 10.36mm 29ppf BTC length 9.5-12.0m

Libya

Casing coupling 13-3/8" N80 12.19mm 68ppf BTC, the quantity 3000 pcs

Casing coupling 9-5/8" L80-1 11.99mm 47ppf BTC, the quantity 3000 pcs

Casing coupling 7" L80-1 10.36mm 29ppf BTC, the quantity 3000 pcs

13.375" casing, 72#, P-110 Grade. Threaded and coupled.

Turkey

Seamless tubing, size: 5-1/2",weight:20 PPF, grade:L80-Type 9CR 1 MO, PSL:1, thread type: premium 04 gas tight connection range 2, quantity: 15000 Mtr

Seamless casing, size: 9-5/8", weight: 47 PPF, grade:L80-Type 9CR 1MO, PSL:1, thread type: premiumgas tight connection range 3, quantity: 34000 Mtr

7" Casing pipes, 23 LB/FT, L80, BTC, R3, API 5CT quantity 20,000 ft

5" Casing, R3, J55, 13 PPF, BTC, API 5 CT quantity 30,000 ft

3 ½ tubing or 2 7/8" drill pipe quantity 20,000 ft

Tunisia

10-3/4" Casing, ERW Carbon Casing, API 5L, Grade B, beveled ends, mills’s standard varnish, Length approx.. 12 meter, OD 273.1 mm, with end protectors, Weight 31.23 LB/Ft, wall thickness 7.09 mm

Casing, 13-3/8", BTC thread, Grade-K55, thickness 9.65mm for 9m, API5CT