Carbon Steel Pipe

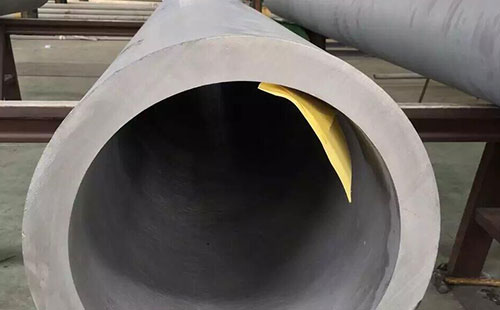

Stainless Steel Pipe

Fittings

OCTG

Steel Structure

Value-Added Products

Clad Pipe

Coated Steel Pipe

Technical Data

Photos

- Stainless steel is an iron alloy that contains a minimum of 10.5% chromium. Alloying elements such as nickel, molybdenum, titanium, carbon, nitrogen, and copper can boost the strength, formability, and other properties of stainless steel. Different alloys offer different levels of corrosion resistance.

Stainless steel alloys offer greater cryogenic toughness, a higher work hardening rate, increased strength and hardness, greater ductility, and a more attractive appearance compared to carbon steel.

| Product Name | Executive Standard | Dimension | Steel Code / Steel Grade |

| Seamless Austenitic Stainless Steel Pipes | ASTM A312/A312M, ASME SA312/SA312M | OD: 1/4"~20" | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| WT: SCH5S~SCH80S | |||

| Seamless Austenitic Stainless Steel Tubing for General Service | ASTM A269, ASME SA269 | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes | ASTM A213/A213M, ASME SA213/SA213M | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| WT: 0.8~10.0mm | |||

| Seamless Duplex Stainless Steel Tubing for General Service | ASTM A789 / A789M | OD: 19.0~60.5mm | S31803, S32205, S32750 |

| WT: 1.2~5.0mm | |||

| Seamless Duplex Stainless Steel Pipes | ASTM A790 / A790M | OD: 3/4"~10" | S31803, S32205, S32750 |

| WT: SCH5S~SCH80S | |||

| Seamless Stainless Steel Mechanical Tubing | ASTM A511 | OD: 6.0~50.8mm | MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

| WT: 1.8~10.0mm | |||

| Seamless Stainless Steel Tubes for Pressure Purposes | EN 10216, DIN 17456, 17458 | OD: 6.0~530.0mm | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

| WT: 0.8~34.0mm |

Application of stainless seamless steel pipe

Chemical plants

Aviation fields

Marine equipment

Cryogenic transportation

Medical & architectural industries

High-Pressure Fuel Lines

Hydraulic Control Applications

Benefits of stainless seamless steel pipe

Stainless steel pipe is resistant to rust and other corrosive attack. It is heat-resistant for high-performance and high-temperature use.

Manufacturing process of stainless seamless steel pipe

Typical methods for manufacturing seamless stainless steel tubing are by extruding, gun drilling or piercing. However, the extrusion process provides the most uniform OD (outside diameter) and ultimately the most concentric ID (inside diameter). In addition, extrusion is the only process most suitable for long length seamless stainless steel coil tubing.

Tests of stainless seamless steel pipe

stainless seamless steel pipe should be manufactured to applicable standards and fully tested for potential defects before being prepared for shipment to the customer.

Outside Diameter Control X-Ray Testing Online Hydrostatic Testing

Hydrotest

After the tube is fully formed to the desired specification it is hydrostatically tested to ensure integrity. Hydrostatic testing determines and verifies the tubing meets the specification. Several types of information can be obtained through this verification process. Key inspection data can be identified through the hydrotest process, such as:

Material flaws

Mechanical properties

Specific hard spots that can fail when hydrogen is present

Finishing

Stainless steel coil tubing can be level wound on spools for shipment or straightened

and cut to specific lengths designated by the customer.

Products can be polished and stenciled with pertinent information for lot traceability and manufacturing identification.

- Out diameter Wall Thickness

1/8" ~ 24" SCH5S/10S/40S/80S/160S/XXS

|

Nominal |

Outside Diameter |

Sch 5S |

Sch 10S |

Sch-40S |

Sch-80S |

Sch-160S |

Sch-XXS |

|||||||

|

mm |

inch |

mm |

WT mm |

Weight (Kg/mt) |

WT mm |

Weight (Kg/mt) |

WT mm |

Weight (Kg/mt) |

WT mm |

Weight (Kg/mt) |

WT mm |

Weight (Kg/mt) |

WT mm |

Weight (Kg/mt) |

|

3 |

1/8 |

10.3 |

1.24 |

0.276 |

1.24 |

0.28 |

1.73 |

0.37 |

2.41 |

0.47 |

- |

- |

- |

- |

|

6 |

1/4 |

13.7 |

1.24 |

0.390 |

1.65 |

0.49 |

2.24 |

0.631 |

3.02 |

0.80 |

- |

- |

- |

- |

|

10 |

3/8 |

17.1 |

1.24 |

0.490 |

1.65 |

0.63 |

2.31 |

0.845 |

3.20 |

1.10 |

- |

- |

- |

- |

|

15 |

1/2 |

21.3 |

1.65 |

0.800 |

2.11 |

1.00 |

2.77 |

1.27 |

3.75 |

1.62 |

4.75 |

1.94 |

7.47 |

2.55 |

|

20 |

3/4 |

26.7 |

1.65 |

1.03 |

2.11 |

1.28 |

2.87 |

1.68 |

3.91 |

2.20 |

5.54 |

2.89 |

7.82 |

3.63 |

|

25 |

1 |

33.4 |

1.65 |

1.30 |

2.77 |

2.09 |

3.38 |

2.50 |

4.55 |

3.24 |

6.35 |

4.24 |

9.09 |

5.45 |

|

32 |

1 1/4 |

42.2 |

1.65 |

1.65 |

2.77 |

2.70 |

3.56 |

3.38 |

4.85 |

4.47 |

6.35 |

5.61 |

9.70 |

7.77 |

|

40 |

1 1/2 |

48.3 |

1.65 |

1.91 |

2.77 |

3.11 |

3.68 |

4.05 |

5.08 |

5.41 |

7.14 |

7.25 |

10.16 |

9.54 |

|

50 |

2 |

60.3 |

1.65 |

2.40 |

2.77 |

3.93 |

3.91 |

5.44 |

5.54 |

7.48 |

8.74 |

11.1 |

11.07 |

13.44 |

|

65 |

2 1/2 |

73.0 |

2.11 |

3.69 |

3.05 |

5.26 |

5.16 |

8.63 |

7.01 |

11.4 |

9.53 |

14.9 |

14.2 |

20.39 |

|

80 |

3 |

88.9 |

2.11 |

4.51 |

3.05 |

6.45 |

5.49 |

11.30 |

7.62 |

15.2 |

11.1 |

21.3 |

15.24 |

27.65 |

|

100 |

4 |

114.3 |

2.11 |

5.84 |

3.05 |

8.36 |

6.02 |

16.07 |

8.56 |

22.3 |

13.49 |

33.54 |

17.12 |

41.03 |

|

125 |

5 |

141.3 |

2.77 |

9.47 |

3.40 |

11.57 |

6.55 |

21.8 |

9.53 |

31.97 |

15.88 |

49.11 |

19.05 |

57.43 |

|

150 |

6 |

168.3 |

2.77 |

11.32 |

3.40 |

13.84 |

7.11 |

28.3 |

10.97 |

42.7 |

18.2 |

67.56 |

21.95 |

79.22 |

|

200 |

8 |

219.1 |

2.77 |

14.79 |

3.76 |

19.96 |

8.18 |

42.6 |

12.7 |

64.6 |

23.0 |

111.2 |

22.23 |

107.8 |

|

250 |

10 |

273.1 |

3.40 |

22.63 |

4.19 |

27.78 |

9.27 |

60.5 |

12.7 |

96.0 |

28.6 |

172.4 |

25.40 |

155.15 |

|

300 |

12 |

323.9 |

3.96 |

31.25 |

4.57 |

36.00 |

9.52 |

73.88 |

12.7 |

132.0 |

33.32 |

238.76 |

25.40 |

186.97 |

|

350 |

14 |

355.6 |

3.96 |

34.36 |

4.78 |

41.3 |

11.13 |

94.59 |

19.05 |

158.08 |

35.71 |

281.70 |

- |

- |

|

400 |

16 |

406.4 |

4.19 |

41.56 |

4.78 |

47.29 |

12.7 |

123.30 |

21.41 |

203.33 |

40.46 |

365.11 |

- |

- |

|

450 |

18 |

457.2 |

4.19 |

46.80 |

4.78 |

53.42 |

14.27 |

155.80 |

23.8 |

254.36 |

45.71 |

466.40 |

- |

- |

|

500 |

20 |

508.0 |

4.78 |

59.25 |

5.54 |

68.71 |

15.09 |

183.42 |

26.19 |

311.2 |

49.99 |

564.68 |

- |

- |

|

600 |

24 |

609.6 |

5.54 |

82.47 |

6.35 |

94.45 |

17.48 |

255.41 |

30.96 |

442.08 |

59.54 |

808.22 |

- |

- |