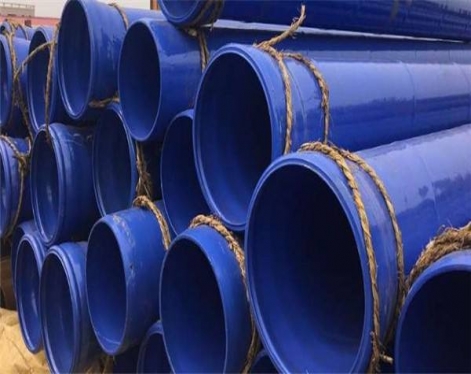

Plastic-coated steel pipe, also known as plastic-coated pipe, steel-plastic composite pipe, and plastic-coated composite steel pipe. The steel-plastic composite steel pipe is based on a seamless pipe or a welded steel pipe, and a plastic anti-corrosion layer is welded on the inner surface of the steel pipe (bottom pipe) by spraying, rolling, dipping, and suction processes, or a plastic anti-corrosion layer is welded on the inner and outer surfaces.

Read more

The surface quenching and tempering heat treatment of ERW straight seam welded pipe is usually carried out by induction heating or flame heating. The main technical parameters are surface hardness, local hardness and effective hardened layer depth.

Read more

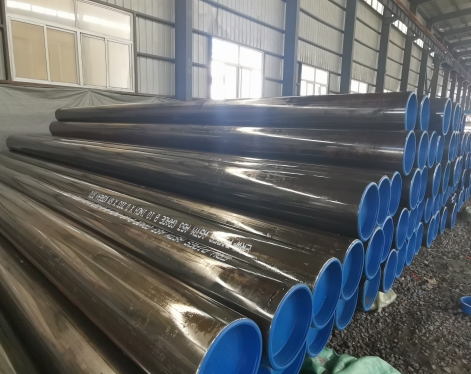

Seamless steel pipe is a steel pipe without weld seam manufactured by hot processing methods such as piercing and hot rolling. If necessary, the hot-worked pipe can be further cold-worked to the required shape, size and performance. At present, seamless steel pipe is the most widely used pipe in petrochemical production equipment (such as octg casing).

Read more

Hot-rolled seamless pipes are relative to cold-rolled seamless pipes. Cold rolling is rolling below the crystallization temperature, and hot rolling is rolling above the recrystallization temperature.

Read more

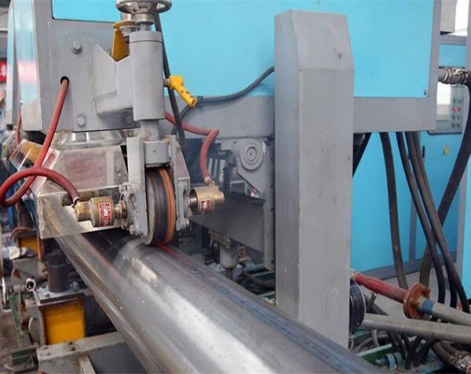

High-frequency welding is a new welding process that uses the skin effect and adjacent effect generated by high-frequency current to connect steel pipes and other metal materials. The emergence and maturity of high-frequency welding technology is a key process in the production of longitudinally welded pipes (ERW). The quality of high-frequency welding directly affects the overall strength, quality level and production speed of the welded pipe.

Read more

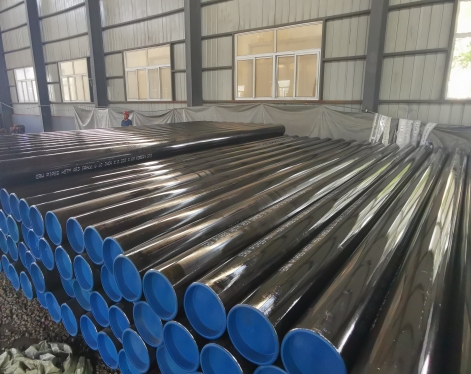

The welded pipe is a steel pipe made of steel plate or strip steel after being crimped and welded, generally with a length of 6 meters. The production process of welded steel pipe is simple, the production efficiency is high, there are many varieties and specifications, and the investment in equipment is small, but the general strength is lower than that of seamless steel pipe.

Read more