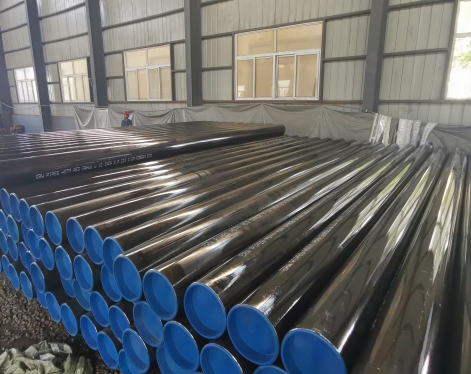

Anti-corrosion steel pipes refer to steel pipes that have been processed by anti-corrosion technology, which can effectively prevent or slow down the corrosion phenomenon caused by chemical or electrochemical reactions during transportation and use. Generally, it refers to the anti-corrosion treatment of ordinary steel pipes (such as seamless pipes and welded pipes) by special processes, so that the steel pipes have certain anti-corrosion capabilities.

Read more

Heat treatment of seamless steel pipe refers to a seamless steel pipe thermal processing process that changes the chemical composition and organization of the surface or interior of the seamless steel pipe to obtain the required properties by means of heating, heat preservation and cooling.

Read more

The tensile test is to make a seamless steel pipe into a sample, pull the sample to fracture on a tensile testing machine, and then measure one or several mechanical properties.

Read more

The small and medium diameter ERW electric welded pipe mainly adopts the continuous roll forming method, and also adopts the row roll forming method

Read more

Steel sheet pile is a kind of section steel with lock. Its section has straight plate shape, groove shape and Z shape, etc., and there are various sizes and interlocking forms. The common ones are Larson type, Lackawanna type and so on. Its advantages are: high strength, easy to drive into hard soil; it can be constructed in deep water, and if necessary, it can be added with oblique supports to form a cage. Good waterproof performance; cofferdams of various shapes can be formed according to needs, and can be reused many times, so it has a wide range of uses.

Read more

Oil well pipe (OCTG pipe), also known as oil special pipe, is a kind of steel pipe specially used for oil and natural gas exploitation. Most of them are seamless pipes, but welded pipes also account for a considerable proportion.

Read more