High pressure boiler tube is a kind of boiler tube, which belongs to the category of seamless steel tube. The manufacturing method is the same as that of seamless pipes, but there are strict requirements on the steel grades used to manufacture steel pipes.

Read more

The finished stainless steel seamless pipe, unless the use occasion is deep underground, the pipe in normal use needs to be polished to ensure that the surface is bright and beautiful. At present, the commonly used polishing methods mainly include mechanical polishing, chemical polishing, and electrochemical polishing.

Read more

The performance of ERW steel pipe can well meet the requirements of long-distance pipeline transportation of oil and gas, so it is widely used in the field of transportation.

Read more

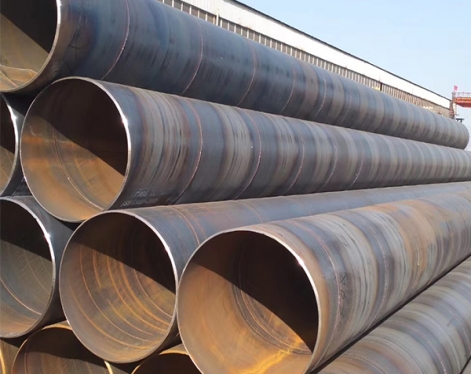

Anti-corrosion spiral steel pipe is mainly used for anti-corrosion of the outer wall of buried or underwater steel oil, gas, water and heating pipelines.

Read more

When the seamless pipe is installed and put into operation, it often expands and contracts due to the difference between the temperature of the medium in the pipe and the ambient temperature during installation.

Read more

The line pipe is a pipeline that transports the oil, gas or water extracted from the ground to the oil and gas industry enterprises through the line pipe. Line pipes include seamless pipes and welded pipes. The pipe ends include flat ends, threaded ends and socket ends; the connection methods are end welding, coupling connection, socket connection, etc.

Read more