Angle steel is a commonly used steel structure that plays a key role in construction (steel structural frames, bridge supports), machinery manufacturing (equipment brackets), and power (transmission towers). The angle steel connection process is the bond that holds components together, directly impacting structural stability and safety. Insecure connections can lead to building collapse and equipment failure. Mastering scientific connection techniques is key to the efficient application of angle steel.

Common connection methods of angle steel

1. Welding connection

Welding is a common method for connecting angle steel. Manual arc welding is flexible, using arc heat to melt the electrode and the workpiece. Gas shielded welding uses carbon dioxide or other materials to block air and prevent oxidation, resulting in consistent quality and high speed. Thick angle steel requires V-shaped grooves to ensure full penetration, positioning to prevent displacement, and symmetrical welding for large pieces to minimize deformation. Post-weld inspection is also necessary for welds to be inspected for defects such as cracks.

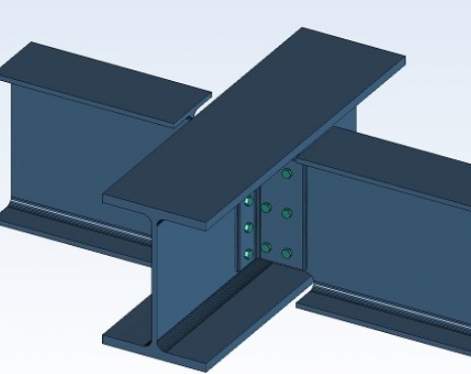

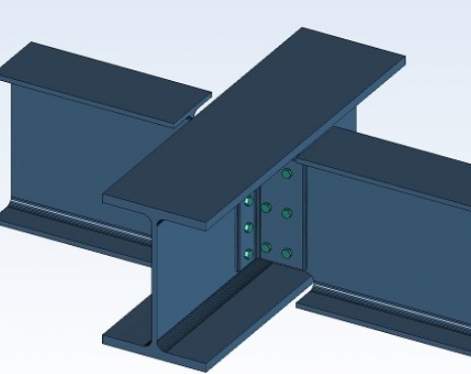

2. Bolted connections

Bolting is simple: First, drill a hole in the angle steel according to the design. The hole diameter must match the bolt (a hole too large will reduce tightness, while a hole too small will make insertion difficult). Then, insert the bolt, insert the washer, and tighten the nut. Bolt specifications should be selected based on the load and environment (e.g., high-strength bolts are recommended for high-tension loads). Tightening torque must be precise (a hole too small will loosen easily, while a hole too large will damage the part). This is usually controlled with a torque wrench.

3. Riveted connection

First, holes are drilled and the rivets are inserted. Tools are then used to press and deform the rivets to secure them. This method can be cold riveted at room temperature or hot riveted with heat (hot riveting requires less effort and offers higher strength after cooling). Compared to welding, riveting offers greater toughness and resistance to shock and vibration, making it suitable for bridges. It is more secure and less prone to loosening than bolts, but the process is more complex and costly, making it suitable for applications such as ships that require high stability and are not frequently disassembled.

Key points for selecting connection process

1. Material factors: Ordinary carbon steel angle steel and stainless steel angle steel are suitable for different welding materials. If the welding material is wrong, it will seriously affect the connection quality (for example, ordinary carbon steel angle steel can be equipped with E4303 welding rods, while stainless steel angle steel requires special stainless steel welding rods);

2. Specification factors: When welding thin angle steel, excessive current will cause burn-through, so low current gas shielded welding is more suitable; when thick angle steel is subjected to heavy loads, the welding needs to focus on the groove form and the number of welding layers to ensure the welding strength;

3. Environmental factors: In scenarios with frequent vibration, riveting or high-strength bolt connections (with good anti-loosening performance) are preferred; in humid and corrosive environments, corrosion-resistant bolts should be used, and the welds should be treated with anti-corrosion treatment after welding;

4. Load-bearing factors: Structures subject to large tensile forces, compressive forces, or bending moments require a connection process determined through calculation. For example, the connection between steel beams and steel columns in large buildings often uses a mixed connection method of welding and high-strength bolts to ensure structural stability.

Read more: Angle Steel Size

Common connection methods of angle steel

1. Welding connection

Welding is a common method for connecting angle steel. Manual arc welding is flexible, using arc heat to melt the electrode and the workpiece. Gas shielded welding uses carbon dioxide or other materials to block air and prevent oxidation, resulting in consistent quality and high speed. Thick angle steel requires V-shaped grooves to ensure full penetration, positioning to prevent displacement, and symmetrical welding for large pieces to minimize deformation. Post-weld inspection is also necessary for welds to be inspected for defects such as cracks.

2. Bolted connections

Bolting is simple: First, drill a hole in the angle steel according to the design. The hole diameter must match the bolt (a hole too large will reduce tightness, while a hole too small will make insertion difficult). Then, insert the bolt, insert the washer, and tighten the nut. Bolt specifications should be selected based on the load and environment (e.g., high-strength bolts are recommended for high-tension loads). Tightening torque must be precise (a hole too small will loosen easily, while a hole too large will damage the part). This is usually controlled with a torque wrench.

3. Riveted connection

First, holes are drilled and the rivets are inserted. Tools are then used to press and deform the rivets to secure them. This method can be cold riveted at room temperature or hot riveted with heat (hot riveting requires less effort and offers higher strength after cooling). Compared to welding, riveting offers greater toughness and resistance to shock and vibration, making it suitable for bridges. It is more secure and less prone to loosening than bolts, but the process is more complex and costly, making it suitable for applications such as ships that require high stability and are not frequently disassembled.

Key points for selecting connection process

1. Material factors: Ordinary carbon steel angle steel and stainless steel angle steel are suitable for different welding materials. If the welding material is wrong, it will seriously affect the connection quality (for example, ordinary carbon steel angle steel can be equipped with E4303 welding rods, while stainless steel angle steel requires special stainless steel welding rods);

2. Specification factors: When welding thin angle steel, excessive current will cause burn-through, so low current gas shielded welding is more suitable; when thick angle steel is subjected to heavy loads, the welding needs to focus on the groove form and the number of welding layers to ensure the welding strength;

3. Environmental factors: In scenarios with frequent vibration, riveting or high-strength bolt connections (with good anti-loosening performance) are preferred; in humid and corrosive environments, corrosion-resistant bolts should be used, and the welds should be treated with anti-corrosion treatment after welding;

4. Load-bearing factors: Structures subject to large tensile forces, compressive forces, or bending moments require a connection process determined through calculation. For example, the connection between steel beams and steel columns in large buildings often uses a mixed connection method of welding and high-strength bolts to ensure structural stability.

Read more: Angle Steel Size