1.ASTM A53 Pipe

ASTM A53 specifications cover seamless and welded steel pipe manufacturing types, carbon steel, and black steel materials. Surface is natural, black and hot dipped galvanized, galvanized steel pipe. Diameter range is NPS 1⁄8 to NPS 26 (10.3mm to 660mm) , nominal wall thickness.For ASTM A53, there are ERW and F, E, S type seamless steel pipes covering grades A and B.

2.ASTM A106 Pipe

ASTM is the American Society for Testing and Materials. It numbers the iron-based materials and non-ferrous materials it writes, also known as standard numbers; A106 is one of the material standard numbers, specifically the standard for seamless carbon steel pipes. Number. It has a wide range of applications, mainly suitable for medium and high temperature working conditions; the pipe diameter range covers NPS 1/8 (DN6) to NPS 48 (DN 1200). A106 is also called SA106. Strictly speaking, after the ASME Association absorbed the ASTM material standard, in order to distinguish it, the prefix S was added to the original standard number.

According to the different chemical compositions of materials specified in the A106 standard (mainly carbon C content), they are divided into three grades, A, B, and C, or material grades GRADE.

A 106 Grade A (or written as A106 Gr.A), the maximum C content is 0.25%.

A 106 Grade B (or written as A106 Gr.B), the maximum C content is 0.30%.

A 106 Grade C (or written as A106 Gr.C), the maximum C content is 0.35%.

In addition to the difference in C content, the manganese content in the above three brands is also slightly different. A106 Gr.A usually has a Mn content of 0.27%~0.93%, A106 Gr.B and A106 Gr.C usually have a Mn content of 0.29%~1.06%. Other elements such as phosphorus P, sulfur S, silicon Si, copper Cu, chromium Cr, molybdenum Mo, nickel Ni, vanadium V, etc. are basically the same, but their total amount should not exceed 1%.

These three material grades have different mechanical properties due to differences in C content. A106-A has the lowest yield strength, and its minimum yield strength is 205MPa, which is basically the same as Chinese10# steel; A106-B has a minimum yield strength of 240MPa, which is close to Chinese20# steel; A106-C has a yield strength of 275MPa.

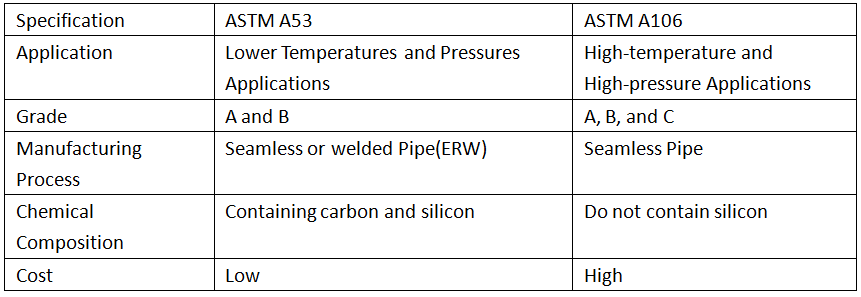

3.ASTM A53 vs ASTM A106 Pipe

The biggest difference between A53 and A106 is pipe meeting the A106 standard can only be seamless.