1. Seamless cold drawn tube meaning

Seamless cold drawn tube (SCDT) is a metal material made by a special process. We can divide this express into multiple phrases to explain.(1)Seamless

Seamless refers to seamless pipe, which is a long steel material with a hollow section and no seams around it. The biggest difference between it and welded pipes is that there are no welds.(2)Cold drawn

Cold drawing is a process in steel pipe manufacturing. The steel is first made into hot-rolled or cold-rolled pipe blanks. It is then drawn through a die at room temperature (cold) to reduce its diameter and wall thickness. This process improves the dimensional accuracy, surface finish and mechanical properties of the pipe.

2. Manufacturing process of cold drawn seamless tube

(1)Prepare raw materials

The steel billet is subjected to surface treatment such as pickling to remove oxide scale, rust and other defects on the metal pipe to obtain high-quality raw materials.(2)Cold drawing deformation

Cold drawing is a key measure in the production process of cold-drawn seamless pipes. The steel billet needs to be turned into a long pipe through a mold at room temperature, which is beneficial to enhancing the dimensional accuracy and mechanical properties of the steel pipe.(3)Annealing

Annealing is a metal heat treatment process that slowly heats metal to a certain temperature, maintains it for a sufficient time, and then cools it at an appropriate speed. The purpose of annealing is mainly to eliminate and improve the structural defects and internal stress left over from the previous process, and to prepare the structure and performance for the subsequent process.(4)Inspection

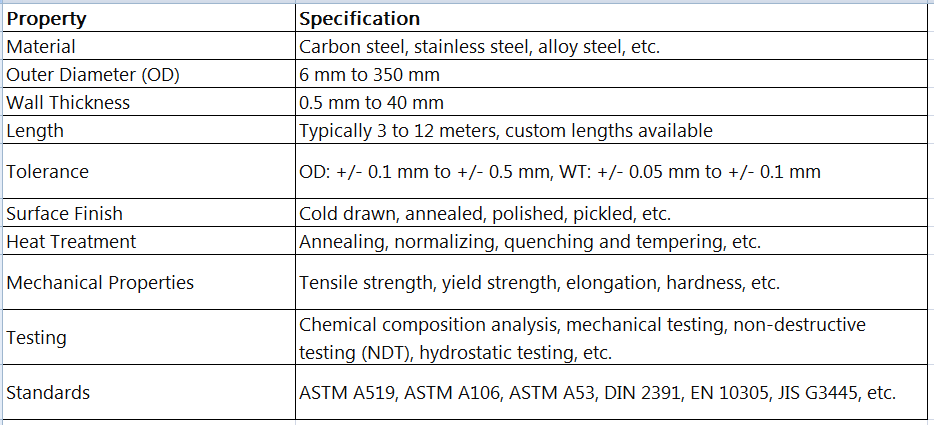

Ultrasonic flaw detection, eddy current flaw detection and other non-destructive testing methods are used to inspect the size, appearance, mechanical properties, etc. of the steel pipe. Once it passes the test, it can be shipped out of the factory.3. Cold-drawn seamless tube specifications

4. ASTM A179 cold drawn seamless pipe

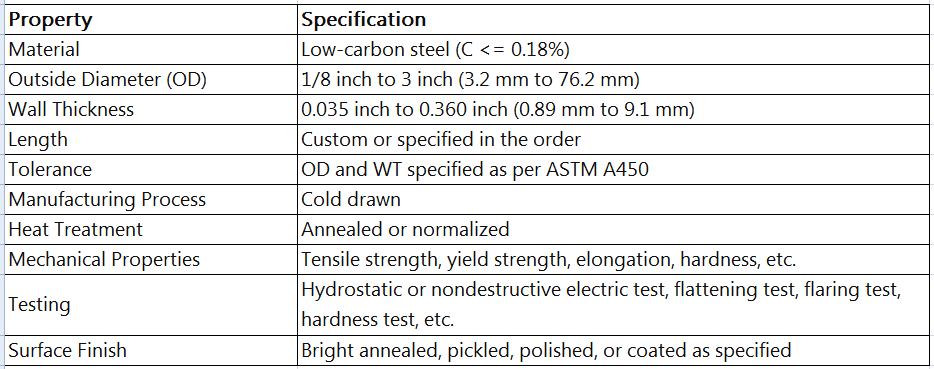

ASTM A179 is a cold-drawn seamless carbon steel boiler tube. This standard specifies the material, size, performance, inspection methods and other requirements for cold-drawn seamless carbon steel boiler tubes. Suitable for manufacturing various high-pressure boilers, heat exchangers, superheaters and other components.ASTM A179 Standard Specifications:

5.4130 cold drawn seamless pipe

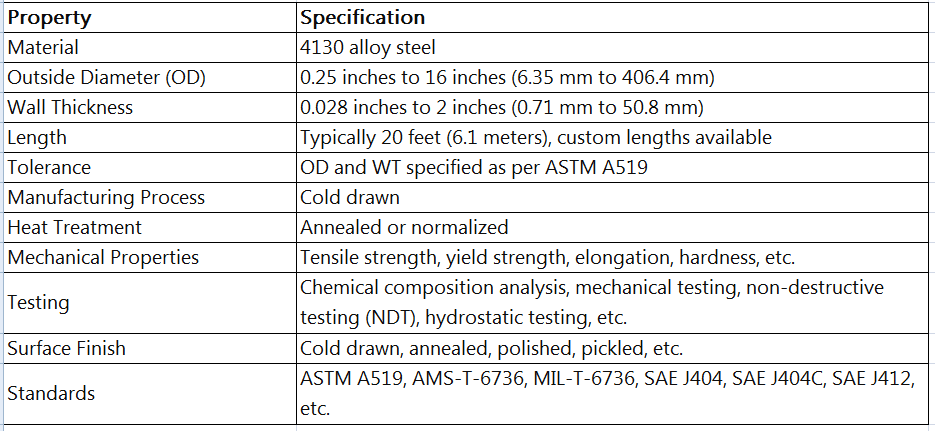

According to ASTM E527 standard (standard name: Designation System for Steel), the specification expression of 4130 cold drawn seamless pipe is:SAE 4130 X101.in:

- SAE 4130 represents steel grade

- X represents processing technology, X represents cold drawing

- 101 represents the steel pipe type, 101 represents the seamless pipe

Specifications for 4130 Cold Drawn Seamless Tubes

6. Advantages and disadvantages of cold drawn seamless pipes

(1)Advantages

①High dimensional accuracySeamless pipe is a high-precision, high-quality steel pipe, and its dimensional accuracy directly affects its applicability and safety. Dimensions include outer diameter, wall thickness, length, etc. Cold drawn tubes have high dimensional accuracy and uniform wall thickness, which is suitable for the manufacturing needs of precision parts.

②Smooth surface

The extrusion effect of the cold drawing process is the main reason for the smooth surface of cold drawn seamless pipes. This process can remove the roughness and oxide scale on the surface of the steel billet, and the finished steel pipe can be used without further surface treatment.

③Strong sealing performance

Seamless pipes have no welds, no welding defects, and have good sealing and safety.

(2)Disadvantages

ExpensiveCold-drawn seamless pipes require special processing equipment because of the additional critical step of cold drawing, and the cost is higher than that of welded pipes.