1.What is pipe sleeve and casing pipe ?

Pipe sleeves and casing pipe are both components of tubing. Tubing is a pipe connector used to connect and secure pipes or fittings. It consists of inner casing, middle casing and outer casing.(1) Casing pipe

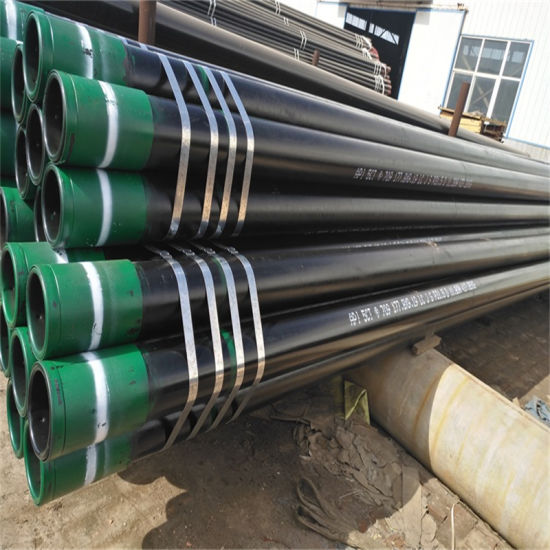

Casing pipe, also called outer casing, is a pipe sleeve formed by one pipe being placed on another pipe. Outer sleeve: The outer sleeve is the outer protective structure of the tubing and is usually made of corrosion-resistant and pressure-resistant materials such as steel or polypropylene. The function of the outer casing is to protect the outer wall of the pipeline and prevent damage to the pipeline from external environmental factors.Oil steel casing pipe is a type of OCTG(Oil Country Tubular Goods) pipe in the oil and gas industry for drilling, production, transportation and control of well fluids. It is usually a long steel pipe installed in oil or natural gas wells to maintain the wellbore structure. The integrity of the well, control of fluid transport, and isolation of fluids in different formations in the well. Petroleum casing has the functions of protecting the wellbore, controlling fluids in the well, and isolating formations.

(2) Pipe sleeves

Pipe sleeves are inner sleeves. The inner sleeve is the internal basic structure of the tube. It is usually made of high temperature and corrosion resistant materials such as stainless steel or plastic. The function of the inner casing is to protect the inner wall of the pipeline and prevent corrosion and leakage.(3) Intermediate casing

The middle casing is the key part connecting the inner casing and the outer casing. It is usually made of elastic material, such as rubber or spring steel, to ensure the tight connection and stability of the sleeve.

2.Pipe sleeve vs casing pipe

There are obvious differences in the definition and structure of casing and pipe sleeves, but they are also different in application scenarios.(1) Differences in application scenarios

Casing is usually used for pipelines buried underground, submarine pipelines, construction pipelines and other pipelines that require long-term protection. The casing not only protects the inner wall of the pipeline, but also prevents the pipeline from being affected by external factors. Pipe sleeves are often used in pipeline systems that require high sealing and wear resistance, such as chemical pipelines, boiler pipelines, etc.(2) Differences in application functions

The application functions of sleeves and sleeves are also different. The casing protects the pipe from corrosion and damage, while also providing some degree of thermal insulation. Pipe sleeves can improve the sealing and wear resistance of the pipe and improve the service life of the pipeline system.3. Summary

Although casing and pipe sleeve have similar names, they are actually two different concepts. In the application of pipeline systems, casings and pipe sleeves need to be selected according to different needs to meet the requirements for pipeline protection, sealing and durability.

Previous:Carbon steel casing pipe

Next:LSAW steel pipe pile