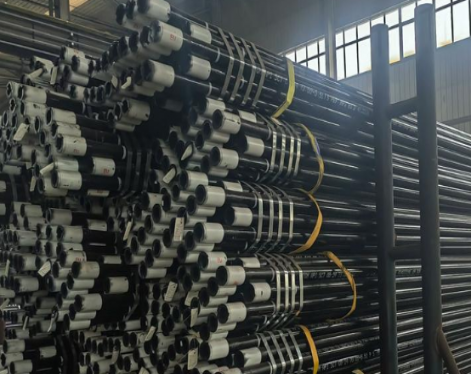

American standard steel pipe export packaging requirements are very strict, fixed-length, bundling, painting, pipe caps, and spray marking must be done. Mainly because of the corrosion of seawater when drifting at sea, seamless steel pipes are generally used to ensure strength and flattening test. Hot-rolled steel pipes are delivered in hot-rolled or heat-treated state; cold-rolled steel is delivered in heat-treated state.

According to different production methods, manufacturing methods can be divided into hot-rolled tubes, cold-rolled tubes, cold-drawn tubes, and extruded tubes. Hot-rolled seamless tubes are generally produced on automatic tube rolling mills. The solid tube is inspected and cleaned of surface defects, cut to the required length, centered on the perforated end of the tube, and then sent to the heating furnace for heating and piercing on the punching machine. Cold drawing is usually carried out on a single-chain or double-chain cold drawing machine of 0.5-100T. In the extrusion method, the heated tube blank is placed in a closed extrusion cylinder, and the perforated rod and the extrusion rod move together to extrude the extruded part from a smaller die hole. This method can produce steel pipes with smaller diameters. Cold-drawn or cold-rolled precision seamless tubes are cold-drawn or cold-rolled precision seamless tubes for mechanical structures and hydraulic equipment with high dimensional accuracy and good surface finish.

Choosing precision seamless pipes to manufacture mechanical structures or hydraulic equipment can greatly save machining man-hours, increase material utilization, and at the same time help improve product quality. Hot-rolled seamless pipes are divided into general steel pipes, low and medium pressure boiler steel pipes, high pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes and other steel pipes, etc.

FAQ:

Q: What is the difference between ASME SA-106 and ASME SA-106M?

A: The difference between ASME SA-106 and ASME SA-106M is that if the size standard is imperial, use ASME SA-106, if the size standard is metric, use ASME SA-106M.