Steel pipes can be divided into two categories according to the manufacturing method: seamless steel pipes and welded steel pipes. Among them, ERW steel pipes are the main type of welded steel pipes. Today, we mainly talk about the two types of steel pipes used as raw materials for oil casing: seamless casing pipe and ERW casing pipe.

Seamless casing pipe - casing pipe made of seamless steel pipe as raw material

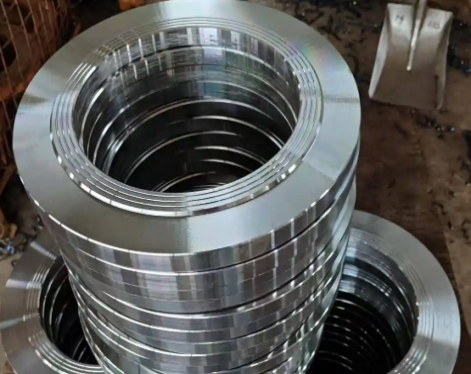

Seamless pipe refers to steel pipe made by four methods: hot rolling, cold rolling, hot drawing and cold drawing. The pipe body itself does not have any welds.

ERW casing pipe- casing pipe made of electric welded pipe as raw material.

ERW (Electric Resistant Weld) pipe refers to a straight seam welded pipe manufactured by high-frequency resistance welding. The raw steel plate (coil) of ERW welded pipe is low-carbon micro-alloy steel rolled by TMCP (Thermo-Mechanical Control Process).

1. Different outer diameter tolerances

Seamless casing pipe : It adopts hot rolling forming process, and its sizing is completed at about 8000C. The raw material composition of the steel pipe, cooling conditions and cooling state of the rolls have a great influence on its outer diameter. Therefore, it is difficult to accurately control the outer diameter and the fluctuation range is large.

ERW casing pipe : It is formed by cold bending and the diameter is fixed by 0.6% diameter reduction. The process temperature is basically constant at room temperature, so the outer diameter is accurately controlled and the fluctuation range is small.

2. Different wall thickness tolerances

Seamless casing pipe : It is produced by round steel perforation, and the wall thickness deviation is large. The subsequent hot rolling can partially eliminate the uneven wall thickness, but the most advanced unit can only control it within ±5-10%t.

ERW casing pipe : hot-rolled coil is used as raw material, and the thickness tolerance of modern hot rolling can be controlled within 0.05mm.

3. Different appearance

The outer surface defects of the billet used in seamless casing pipe cannot be eliminated through hot rolling process, and can only be polished off after the finished product is completed; the spiral track left after perforation can only be partially eliminated during the wall reduction process.

ERW casing pipe uses hot-rolled coil as raw material. The surface quality of the coil is the surface quality of the ERW steel pipe. The surface quality of the hot-rolled coil is easy to control and has high quality. Therefore, the surface quality of the ERW steel pipe is much better than that of the seamless steel pipe.

4. Different ellipticity

Seamless casing pipe : Hot rolling forming process is adopted. The raw material composition, cooling conditions and cooling state of the rolls of the steel pipe have a great influence on its outer diameter. Therefore, it is difficult to accurately control the outer diameter and the fluctuation range is large.

ERW casing pipe : Cold bending forming is adopted, so the outer diameter control is accurate and the fluctuation range is small.

Compared with seamless casing pipe , the advantages and disadvantages of ERW casing pipe are as follows:

Advantages:

Low cost: adopts steel plate coil welding process, high production efficiency, high material utilization rate, and the cost is about 20%-30% lower than seamless casing.

Flexible specifications: can produce casings of various diameters and wall thicknesses by adjusting the size of steel plates, suitable for large-scale standardized production.

Convenient construction: regular welds, mature welding technology, high installation efficiency, suitable for fast construction scenarios (such as municipal pipelines, building structures).

High precision: small dimensional tolerance, good uniformity of pipe wall thickness, easy to connect and seal pipelines.

Disadvantages:

1. Limited strength: There is a risk of stress concentration at the weld, and the overall strength and fatigue resistance are lower than those of seamless casing, and it may crack under high pressure.

2. Limited application scenarios: It is not suitable for high pressure, high corrosion or complex stress conditions (such as deep oil and gas wells, submarine pipelines), and is mainly used in medium and low pressure scenarios (shallow drilling, water and gas pipelines).

3. Process limitations: Due to the width of the steel plate, the production of large-diameter ERW casing is difficult, and welds are usually required to be spliced, which further reduces reliability.

4. Weak corrosion resistance: The weld area is prone to structural changes due to the influence of welding heat. If not handled properly, it may become a weak point for corrosion.

Read more: Advantages and Disadvantages of Stainless Steel ERW Pipe

Seamless casing pipe - casing pipe made of seamless steel pipe as raw material

Seamless pipe refers to steel pipe made by four methods: hot rolling, cold rolling, hot drawing and cold drawing. The pipe body itself does not have any welds.

ERW casing pipe- casing pipe made of electric welded pipe as raw material.

ERW (Electric Resistant Weld) pipe refers to a straight seam welded pipe manufactured by high-frequency resistance welding. The raw steel plate (coil) of ERW welded pipe is low-carbon micro-alloy steel rolled by TMCP (Thermo-Mechanical Control Process).

1. Different outer diameter tolerances

Seamless casing pipe : It adopts hot rolling forming process, and its sizing is completed at about 8000C. The raw material composition of the steel pipe, cooling conditions and cooling state of the rolls have a great influence on its outer diameter. Therefore, it is difficult to accurately control the outer diameter and the fluctuation range is large.

ERW casing pipe : It is formed by cold bending and the diameter is fixed by 0.6% diameter reduction. The process temperature is basically constant at room temperature, so the outer diameter is accurately controlled and the fluctuation range is small.

2. Different wall thickness tolerances

Seamless casing pipe : It is produced by round steel perforation, and the wall thickness deviation is large. The subsequent hot rolling can partially eliminate the uneven wall thickness, but the most advanced unit can only control it within ±5-10%t.

ERW casing pipe : hot-rolled coil is used as raw material, and the thickness tolerance of modern hot rolling can be controlled within 0.05mm.

3. Different appearance

The outer surface defects of the billet used in seamless casing pipe cannot be eliminated through hot rolling process, and can only be polished off after the finished product is completed; the spiral track left after perforation can only be partially eliminated during the wall reduction process.

ERW casing pipe uses hot-rolled coil as raw material. The surface quality of the coil is the surface quality of the ERW steel pipe. The surface quality of the hot-rolled coil is easy to control and has high quality. Therefore, the surface quality of the ERW steel pipe is much better than that of the seamless steel pipe.

4. Different ellipticity

Seamless casing pipe : Hot rolling forming process is adopted. The raw material composition, cooling conditions and cooling state of the rolls of the steel pipe have a great influence on its outer diameter. Therefore, it is difficult to accurately control the outer diameter and the fluctuation range is large.

ERW casing pipe : Cold bending forming is adopted, so the outer diameter control is accurate and the fluctuation range is small.

Compared with seamless casing pipe , the advantages and disadvantages of ERW casing pipe are as follows:

Advantages:

Low cost: adopts steel plate coil welding process, high production efficiency, high material utilization rate, and the cost is about 20%-30% lower than seamless casing.

Flexible specifications: can produce casings of various diameters and wall thicknesses by adjusting the size of steel plates, suitable for large-scale standardized production.

Convenient construction: regular welds, mature welding technology, high installation efficiency, suitable for fast construction scenarios (such as municipal pipelines, building structures).

High precision: small dimensional tolerance, good uniformity of pipe wall thickness, easy to connect and seal pipelines.

Disadvantages:

1. Limited strength: There is a risk of stress concentration at the weld, and the overall strength and fatigue resistance are lower than those of seamless casing, and it may crack under high pressure.

2. Limited application scenarios: It is not suitable for high pressure, high corrosion or complex stress conditions (such as deep oil and gas wells, submarine pipelines), and is mainly used in medium and low pressure scenarios (shallow drilling, water and gas pipelines).

3. Process limitations: Due to the width of the steel plate, the production of large-diameter ERW casing is difficult, and welds are usually required to be spliced, which further reduces reliability.

4. Weak corrosion resistance: The weld area is prone to structural changes due to the influence of welding heat. If not handled properly, it may become a weak point for corrosion.

Read more: Advantages and Disadvantages of Stainless Steel ERW Pipe