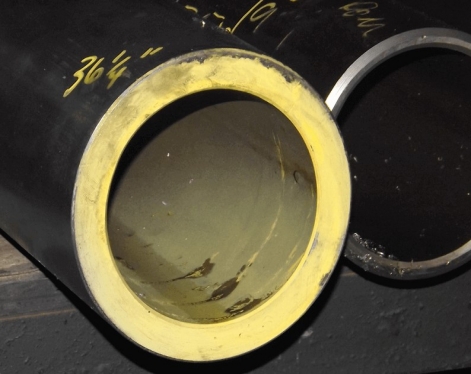

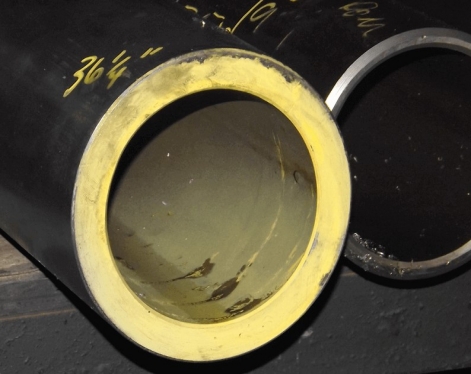

Seamless mechanical tube, full name "seamless steel tube for mechanical structure", refers to the steel pipe manufactured by the process of no welding seams, which is specially used for mechanical equipment structural parts, transmission parts or supporting parts. The core features are no weld defects, high dimensional accuracy, and uniform mechanical properties. They can meet the stringent requirements for strength and toughness during mechanical operation and widely comply with industry standards such as GB/T 8162 (China), ASTM A53 (USA), and DIN 2391 (Germany).

Core definition of seamless mechanical tube

The most critical feature of seamless mechanical tubes is the absence of welded seams. Solid steel billets (such as round steel) are directly formed into tubes through processes such as hot extrusion, cold drawing or hot rolling, without any steel plate coiling or welding steps. Therefore, there is no risk of weak points, pores or cracks at the welds.

Ordinary seamed pipes (such as straight seam welded pipes and spiral welded pipes) require the steel plates to be curled into tubes and then welded into shape. The welds are prone to become weak points in mechanical performance and cannot meet the mechanical structure's requirement of "uniform stress across the entire cross-section." This is also the core reason why seamless mechanical tubes have become the first choice for core mechanical components.

Manufacturing process of mechanical tube

The mainstream production processes are divided into two categories: "hot rolling" and "cold drawing", which are adapted to different precision requirements:

1. Hot rolled seamless mechanical tube:

The process is "heating the steel billet → perforating (to make hollow capillary tubes) → hot rolling and sizing → straightening → flaw detection → cutting". The finished product's outer diameter usually ranges from 32-630mm, with a wall thickness of 2.5-75mm. It is characterized by high production efficiency and low cost, and is suitable for heavy machinery supports with low precision requirements (such as machine tool bed columns and equipment base brackets).

Hot-finished seamless mechanical tubing---Wall Thickness Tolerances

2. Cold drawn seamless mechanical tube:

By adding the "pickling and rust removal → cold drawing → annealing and softening → finishing" processes to the hot-rolled rough tube, the outer diameter of the finished product can be as small as 6mm, the wall thickness accuracy is controlled within ±0.1mm, and the surface roughness reaches Ra1.6-6.3μm, making it suitable for high-precision mechanical parts (such as hydraulic cylinder barrels, drive shaft sleeves, and precision instrument housings).

Cold drawn seamless mechanical tubing---Wall Thickness Tolerances

Core properties of seamless mechanical tubes

Typical application scenarios

Core definition of seamless mechanical tube

The most critical feature of seamless mechanical tubes is the absence of welded seams. Solid steel billets (such as round steel) are directly formed into tubes through processes such as hot extrusion, cold drawing or hot rolling, without any steel plate coiling or welding steps. Therefore, there is no risk of weak points, pores or cracks at the welds.

Ordinary seamed pipes (such as straight seam welded pipes and spiral welded pipes) require the steel plates to be curled into tubes and then welded into shape. The welds are prone to become weak points in mechanical performance and cannot meet the mechanical structure's requirement of "uniform stress across the entire cross-section." This is also the core reason why seamless mechanical tubes have become the first choice for core mechanical components.

Manufacturing process of mechanical tube

The mainstream production processes are divided into two categories: "hot rolling" and "cold drawing", which are adapted to different precision requirements:

1. Hot rolled seamless mechanical tube:

The process is "heating the steel billet → perforating (to make hollow capillary tubes) → hot rolling and sizing → straightening → flaw detection → cutting". The finished product's outer diameter usually ranges from 32-630mm, with a wall thickness of 2.5-75mm. It is characterized by high production efficiency and low cost, and is suitable for heavy machinery supports with low precision requirements (such as machine tool bed columns and equipment base brackets).

Hot-finished seamless mechanical tubing---Wall Thickness Tolerances

| Wall ThicknessPercent of OD | Maximum Percent Over & Under Nominal | Wall ThicknessPercent of OD | Maximum Percent Over & Under Nominal |

| OD 2” and Over | OD 50.08mm and Over | ||

| Under 10 10 to 25 |

10.0 7.5 |

Under 10 10 to 25 |

10.0 7.5 |

2. Cold drawn seamless mechanical tube:

By adding the "pickling and rust removal → cold drawing → annealing and softening → finishing" processes to the hot-rolled rough tube, the outer diameter of the finished product can be as small as 6mm, the wall thickness accuracy is controlled within ±0.1mm, and the surface roughness reaches Ra1.6-6.3μm, making it suitable for high-precision mechanical parts (such as hydraulic cylinder barrels, drive shaft sleeves, and precision instrument housings).

Cold drawn seamless mechanical tubing---Wall Thickness Tolerances

| Wall ThicknessPercent of OD | Maximum Percent Over & Under Nominal | Wall ThicknessPercent of OD | Maximum Percent Over & Under Nominal | ||

| Under 1.499” ID | 1.500” ID & Over | Under 38.07mm ID | 38.07mm ID & Over | ||

| Under 10 | 10.0 | 7.5 | Under 10 | 10.0 | 7.5 |

| 10 to 25 | 10.0 | 6.0 | 10 to 25 | 10.0 | 6.0 |

| Over 25 | 12.5 | 7.5 | Over 25 | 12.5 | 7.5 |

Core properties of seamless mechanical tubes

1. Uniform and stable mechanical properties: There is no strength difference caused by welds, and the tensile strength, yield strength, and impact toughness are consistent across the entire cross-section. It can withstand vibration, impact, and alternating loads during mechanical operation and is not prone to breakage due to local weak points.

2. High dimensional accuracy: The cold drawing process can achieve high-precision control of outer diameter and wall thickness, with a straightness error of ≤1mm/m, which facilitates precise coordination with other mechanical components, reduces assembly clearances, and improves equipment operation stability (for example, it can reduce the risk of oil leakage in hydraulic systems).

3. Good processing performance: drilling, tapping, bending, and heat treatment (such as tempering and quenching) can be performed directly without worrying about cracking at the weld, and it is suitable for the complex processing needs of mechanical parts.

4. Wide material adaptability: Commonly used materials include low carbon steel (Q235, 20#), medium carbon steel (45#), alloy steel (40Cr, 20CrMnTi) and stainless steel (304, 316). Low carbon steel focuses on cost-effectiveness, alloy steel focuses on high strength, and stainless steel focuses on corrosion resistance. They can match different mechanical working conditions (such as Q235 for general equipment and 40Cr for precision transmission parts).

Typical application scenarios

1. General mechanical equipment: spindle sleeves of machine tools, support shafts of gear boxes, guide columns of stamping equipment;

2. Hydraulic and transmission systems: hydraulic cylinder barrels, cylinder tubes, and hydraulic pipelines of excavators;

3. Heavy machinery: crane boom support tubes, loader frame structure tubes;

4. Precision instruments: transmission parts of medical equipment, shell frames of electronic equipment.

Read more: Mechanical Tube vs Hydraulic Tube

Read more: Mechanical Tube vs Hydraulic Tube