To store seamless pipes, choose a suitable site and warehouse

1) The site or warehouse for steel storage should be selected in a clean and well-drained place, away from factories and mines that produce harmful gases or dust. Weeds and all debris should be removed on the site to keep the steel clean

2) Do not stack together with acid, alkali, salt, cement and other materials that are corrosive to steel in the warehouse. Different types of steel should be stacked separately to prevent confusion and prevent contact corrosion

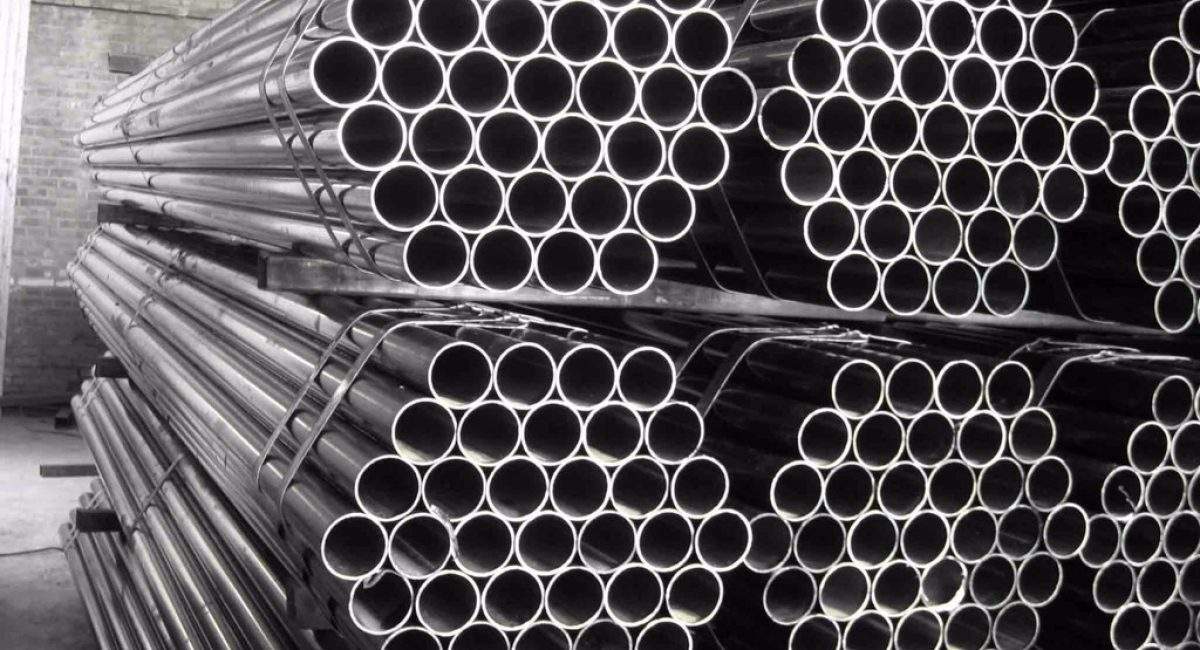

3) Large-scale steel, rails, steel plates, large-diameter steel pipes, forgings, etc. can be stacked in the open air

4) Small and medium-sized steel bars, wire rods, steel bars, medium-caliber steel pipes, steel wires, and wire ropes can be stored in a well-ventilated material shed, but must be covered with thatch

5) Some small steel products, thin steel plates, steel strips, silicon steel sheets, small-diameter or thin-walled steel pipes, various cold-rolled and cold-drawn steel products, and high-priced and corrosive metal products can be stored in the warehouse

6) The warehouse should be selected according to the geographical conditions. Generally, an ordinary closed warehouse is used, that is, a warehouse with a roof, a wall, tight doors and windows, and a ventilation device.

7) The warehouse requires ventilation in sunny days, closed and moisture-proof in rainy days, and always maintains a suitable storage environment

The stacking requirements for seamless pipes are: reasonable stacking, advanced first

1) The principle of stacking is to stack according to the variety and specification under the condition of stable stacking and ensuring safety. Different types of materials should be stacked separately to prevent confusion and mutual corrosion

2) It is forbidden to store items that are corrosive to steel near the stack

3) The bottom of the pile should be high, firm and flat to prevent the material from being damp or deformed

4) The same kind of materials are stacked separately according to the order of storage, which is convenient for the implementation of the principle of first delivery

5) For the steel pipes stacked in the open air, there must be wooden pads or stone strips underneath, and the stacking surface is slightly inclined to facilitate drainage, and attention should be paid to placing the materials straight to prevent bending deformation

6) Stacking height, manual operation shall not exceed 1.2m, mechanical operation shall not exceed 1.5m, stack width shall not exceed 2.5m

7) There should be a certain channel between the stacks, the inspection channel is generally 0.5m, and the access channel depends on the size of the material and the transport machinery, generally 1.5-2.0m

8) The bottom of the stack is raised. If the warehouse is on a sunny concrete floor, it can be raised by 0.1m; if it is a mud floor, it must be raised by 0.2-0.5m. If it is an open field, the cement floor shall be raised 0.3-0.5m, and the sand and mud surface shall be raised 0.5-0.7m.

1) The site or warehouse for steel storage should be selected in a clean and well-drained place, away from factories and mines that produce harmful gases or dust. Weeds and all debris should be removed on the site to keep the steel clean

2) Do not stack together with acid, alkali, salt, cement and other materials that are corrosive to steel in the warehouse. Different types of steel should be stacked separately to prevent confusion and prevent contact corrosion

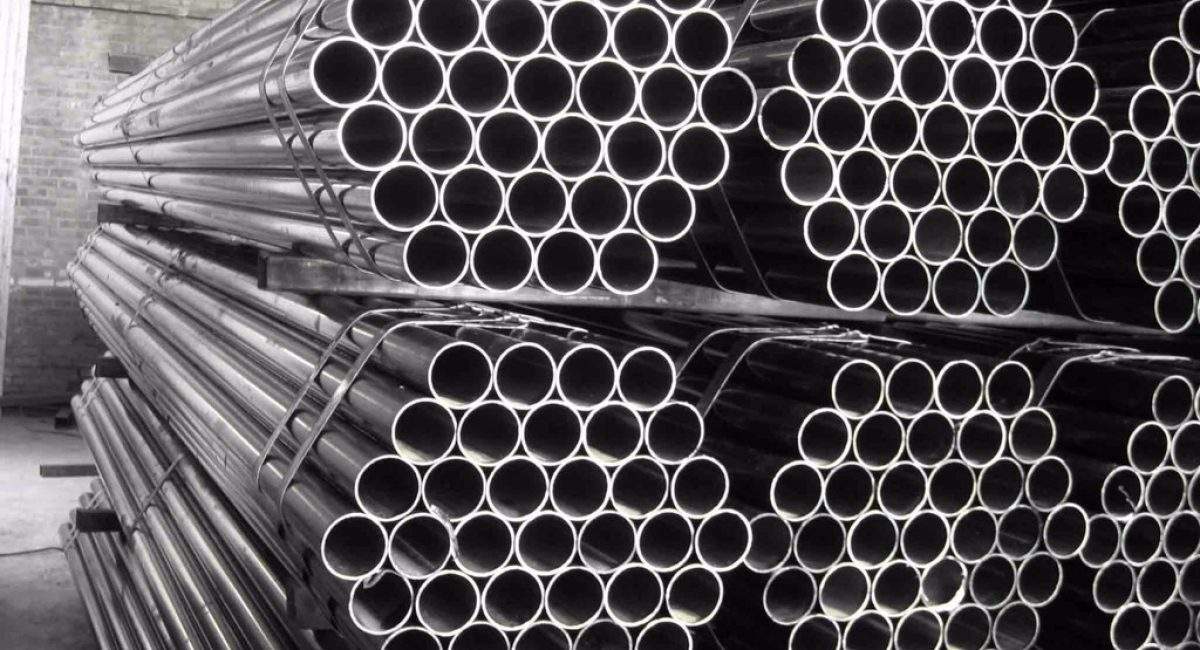

3) Large-scale steel, rails, steel plates, large-diameter steel pipes, forgings, etc. can be stacked in the open air

4) Small and medium-sized steel bars, wire rods, steel bars, medium-caliber steel pipes, steel wires, and wire ropes can be stored in a well-ventilated material shed, but must be covered with thatch

5) Some small steel products, thin steel plates, steel strips, silicon steel sheets, small-diameter or thin-walled steel pipes, various cold-rolled and cold-drawn steel products, and high-priced and corrosive metal products can be stored in the warehouse

6) The warehouse should be selected according to the geographical conditions. Generally, an ordinary closed warehouse is used, that is, a warehouse with a roof, a wall, tight doors and windows, and a ventilation device.

7) The warehouse requires ventilation in sunny days, closed and moisture-proof in rainy days, and always maintains a suitable storage environment

The stacking requirements for seamless pipes are: reasonable stacking, advanced first

1) The principle of stacking is to stack according to the variety and specification under the condition of stable stacking and ensuring safety. Different types of materials should be stacked separately to prevent confusion and mutual corrosion

2) It is forbidden to store items that are corrosive to steel near the stack

3) The bottom of the pile should be high, firm and flat to prevent the material from being damp or deformed

4) The same kind of materials are stacked separately according to the order of storage, which is convenient for the implementation of the principle of first delivery

5) For the steel pipes stacked in the open air, there must be wooden pads or stone strips underneath, and the stacking surface is slightly inclined to facilitate drainage, and attention should be paid to placing the materials straight to prevent bending deformation

6) Stacking height, manual operation shall not exceed 1.2m, mechanical operation shall not exceed 1.5m, stack width shall not exceed 2.5m

7) There should be a certain channel between the stacks, the inspection channel is generally 0.5m, and the access channel depends on the size of the material and the transport machinery, generally 1.5-2.0m

8) The bottom of the stack is raised. If the warehouse is on a sunny concrete floor, it can be raised by 0.1m; if it is a mud floor, it must be raised by 0.2-0.5m. If it is an open field, the cement floor shall be raised 0.3-0.5m, and the sand and mud surface shall be raised 0.5-0.7m.