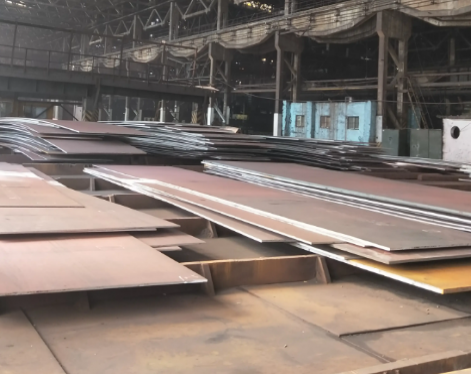

For hot-rolled thin-walled seamless pipes with rough product defects, inspection before rolling is to find surface abnormalities. However, after grinding and pickling, it was found that there were "dark spots" on the surface of the tube blank. Metallographic examination showed that the dark spots corresponded to coarse grains.The "dark spot" is mainly concentrated in the middle part of the width direction of the tube blank; it persists along the length of the tube blank (the severity will change); the upper and lower surfaces appear correspondingly, and the upper surface is more serious. Coarse surface defects will have extremely adverse effects on downstream production and customer use. The "dark spots" caused by coarse grain defects cannot be eliminated by the cold rolling line, resulting in dark spots with a "fish scale" appearance on the finished plate.

Causes of coarse grain defects in thin-walled seamless tubes:

1. Too small reduction in rough rolling area causes abnormal growth of austenite grains on the surface of the strip;

2. The excessively high coiling temperature leads to the accumulation of strain energy on the surface of the strip, and the grains have sufficient power to grow, resulting in abnormal growth;

3. The surface temperature of the thin-walled seamless steel pipe in the finishing rolling area is too low, and two-phase critical zone rolling occurs. During the rolling process, some ferrite grains are generated on the surface of the strip steel.These ferrite grains undergo deformation during rolling and accumulate deformation energy. Since ferrite cannot recrystallize in this temperature range, after coiling, the ferrite in this region in the phase transformation completes the release of strain energy in the form of grain boundary migration and annexation of surrounding grains:

4. Before coiling, the pinch roller has a light pressing effect on the surface of the strip, causing friction and deformation of the surface of the strip. Since the strip may still be in the a+y two-phase region at the coiling temperature, the surface strain of the strip induces phase transformation, and grain boundary migration occurs in this region after coiling, resulting in abnormal growth.

Control of Coarse Grain Defects:

By reducing the pressure of the coiling pinch roller, improving the direct inducement, and by adjusting the laminar cooling and coiling temperature to promote the phase transformation of the strip surface as soon as possible, and improving the internal cause of the structure can help reduce the occurrence of this defect.

Causes of coarse grain defects in thin-walled seamless tubes:

1. Too small reduction in rough rolling area causes abnormal growth of austenite grains on the surface of the strip;

2. The excessively high coiling temperature leads to the accumulation of strain energy on the surface of the strip, and the grains have sufficient power to grow, resulting in abnormal growth;

3. The surface temperature of the thin-walled seamless steel pipe in the finishing rolling area is too low, and two-phase critical zone rolling occurs. During the rolling process, some ferrite grains are generated on the surface of the strip steel.These ferrite grains undergo deformation during rolling and accumulate deformation energy. Since ferrite cannot recrystallize in this temperature range, after coiling, the ferrite in this region in the phase transformation completes the release of strain energy in the form of grain boundary migration and annexation of surrounding grains:

4. Before coiling, the pinch roller has a light pressing effect on the surface of the strip, causing friction and deformation of the surface of the strip. Since the strip may still be in the a+y two-phase region at the coiling temperature, the surface strain of the strip induces phase transformation, and grain boundary migration occurs in this region after coiling, resulting in abnormal growth.

Control of Coarse Grain Defects:

By reducing the pressure of the coiling pinch roller, improving the direct inducement, and by adjusting the laminar cooling and coiling temperature to promote the phase transformation of the strip surface as soon as possible, and improving the internal cause of the structure can help reduce the occurrence of this defect.