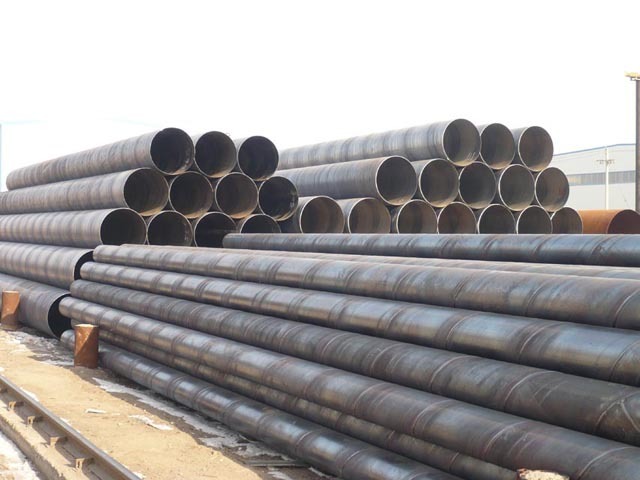

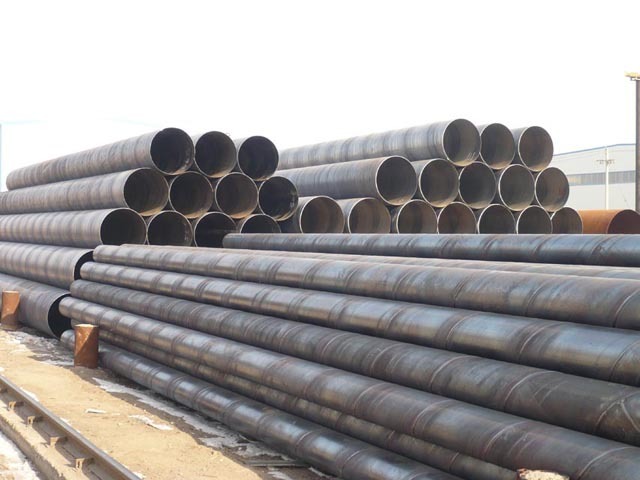

Spiral seam submerged arc welded steel pipe (SSAW pipe) refers to a metal pipe with a spiral seam welded by submerged arc welding process. Widely used in water supply engineering, petrochemical industry (such as octg casing), chemical industry, electric power industry, agricultural irrigation, urban construction,

The technical elements added to different raw materials of spiral steel pipes are different, and the mechanical properties and physical and chemical properties of the tomb users are different. The following will introduce the effect of the addition of rare metal elements on the pipe body.

1. Carbon is the most basic element in steel, and the level of carbon content is the basis for distinguishing steel from iron. Generally, when the carbon content is 1.7%, it is iron. The carbon content directly affects the properties of the steel. When the carbon content is high, the hardness and strength of the steel increase, but its melting point, plasticity and ductility decrease, making the steel difficult to process.

2. Nickel is a ferromagnetic metal element, which can be highly polished and corrosion-resistant. Mainly used in alloys (such as nickel steel and nickel silver) and as catalysts (such as Raney nickel, especially for hydrogenation catalysts)

3. The main function of chromium is anti-corrosion, which is commonly used in stainless steel. The reason is that when alloying the steel with chromium, it changes the type of surface oxide to a surface oxide similar to that formed on pure chromium metal. This tightly adhered chromium-rich oxide protects the surface from further oxidation.

The technical elements added to different raw materials of spiral steel pipes are different, and the mechanical properties and physical and chemical properties of the tomb users are different. The following will introduce the effect of the addition of rare metal elements on the pipe body.

1. Carbon is the most basic element in steel, and the level of carbon content is the basis for distinguishing steel from iron. Generally, when the carbon content is 1.7%, it is iron. The carbon content directly affects the properties of the steel. When the carbon content is high, the hardness and strength of the steel increase, but its melting point, plasticity and ductility decrease, making the steel difficult to process.

2. Nickel is a ferromagnetic metal element, which can be highly polished and corrosion-resistant. Mainly used in alloys (such as nickel steel and nickel silver) and as catalysts (such as Raney nickel, especially for hydrogenation catalysts)

3. The main function of chromium is anti-corrosion, which is commonly used in stainless steel. The reason is that when alloying the steel with chromium, it changes the type of surface oxide to a surface oxide similar to that formed on pure chromium metal. This tightly adhered chromium-rich oxide protects the surface from further oxidation.