Nowadays, the surface of the welded tubes we use are required to be coated for corrosion protection. The common anticorrosion coatings for welded tubes are petroleum asphalt, epoxy coal tar asphalt, PE sheath and PE foam sheath, epoxy powder, coal tar enamel and three-layer composite structure. The more used pipe anti-corrosion methods are 3PE composite structure and single-layer powder epoxy resin. So do you know how the welded tube is anti-corrosion?

1)Coating anti-corrosion

Coating anti-corrosion refers to the uniform, dense coating on the surface of the rusted metal tube to isolate it from various corrosive media. This method of corrosion protection is usually used for steel tubes. Coating anti-corrosion materials are brushed coatings, which are paints, but with special properties that act as isolators. These materials and structures have better dielectric properties, physical properties, chemical properties and temperature range. Composite materials or anti-corrosion coatings that meet the structural requirements are widely used in our pipelines.

2) Cold-wrap tape

Cold-wrap tape has the advantages of corrosion resistance and simple operation. But weak adhesion, low waterproof function and low strength are its weaknesses, and it is greatly influenced by the environment. Epoxy powder anti-corrosion, using electrostatic spraying method. Good integration with the same material anti-corrosion tube body, strong adhesion, but poor water resistance of epoxy powder (high water absorption rate, up to 0.83%).

3)Electrochemical anti-corrosion

Electrochemical anti-corrosion is mainly cathodic protection. The welded tube pipeline is transported in a liquid or gas, if it is a liquid, you can add rust inhibitor or anticorrosion agent, if the steel pipe dimension is relatively large, and the transported liquid allows, you can add a sacrificial anode.

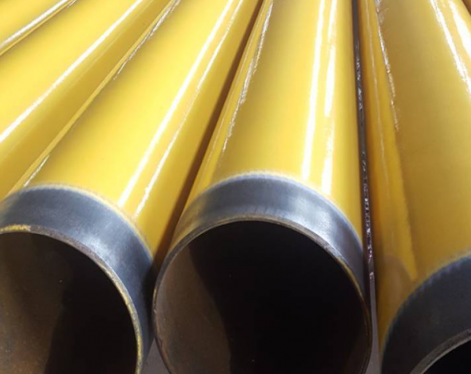

4) Add heat insulation and anti-corrosion composite layer

Adding heat insulation and anti-corrosion compound layer on the surface of welded tube can reduce the heat dissipation to soil on medium and small diameter pipes transporting crude oil or fuel oil. Rigid polyurethane foam is a relatively common insulation material with a soft texture and a temperature of -185 to 95°C. To improve the strength, a high-density polyethylene layer is added to the outside of the insulation layer to form a composite structure that can prevent groundwater from penetrating into the insulation layer.

Welded tube is a steel tube made of steel plate or strip after being rolled and formed and welded. Its production process is simple, with high production efficiency, many varieties and specifications, and low investment in equipment, but its strength is generally lower than that of seamless steel pipe.

1)Coating anti-corrosion

Coating anti-corrosion refers to the uniform, dense coating on the surface of the rusted metal tube to isolate it from various corrosive media. This method of corrosion protection is usually used for steel tubes. Coating anti-corrosion materials are brushed coatings, which are paints, but with special properties that act as isolators. These materials and structures have better dielectric properties, physical properties, chemical properties and temperature range. Composite materials or anti-corrosion coatings that meet the structural requirements are widely used in our pipelines.

2) Cold-wrap tape

Cold-wrap tape has the advantages of corrosion resistance and simple operation. But weak adhesion, low waterproof function and low strength are its weaknesses, and it is greatly influenced by the environment. Epoxy powder anti-corrosion, using electrostatic spraying method. Good integration with the same material anti-corrosion tube body, strong adhesion, but poor water resistance of epoxy powder (high water absorption rate, up to 0.83%).

3)Electrochemical anti-corrosion

Electrochemical anti-corrosion is mainly cathodic protection. The welded tube pipeline is transported in a liquid or gas, if it is a liquid, you can add rust inhibitor or anticorrosion agent, if the steel pipe dimension is relatively large, and the transported liquid allows, you can add a sacrificial anode.

4) Add heat insulation and anti-corrosion composite layer

Adding heat insulation and anti-corrosion compound layer on the surface of welded tube can reduce the heat dissipation to soil on medium and small diameter pipes transporting crude oil or fuel oil. Rigid polyurethane foam is a relatively common insulation material with a soft texture and a temperature of -185 to 95°C. To improve the strength, a high-density polyethylene layer is added to the outside of the insulation layer to form a composite structure that can prevent groundwater from penetrating into the insulation layer.

Welded tube is a steel tube made of steel plate or strip after being rolled and formed and welded. Its production process is simple, with high production efficiency, many varieties and specifications, and low investment in equipment, but its strength is generally lower than that of seamless steel pipe.