Both steel pipe piles and steel sheet piles are structural members used in construction projects, but they differ in shape, application and installation method.Steel pipe piles and steel sheet piles are both types of structural elements used in construction projects, but they have different shapes, applications, and installation methods

Read more

Square tube (such as a500 square tube) is a hollow square cross-section light-weight thin-walled steel tube, also known as steel cold-formed profile. It is a section steel with a square cross-section shape and size made of hot-rolled or cold-rolled strip or coil as the base material, which is cold-bent and then high-frequency welded.

Read more

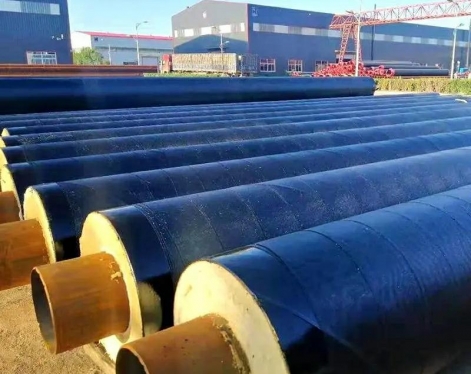

Insulation spiral steel pipe is to insulate spiral steel pipe (SSAW pipe). The most important method of heat preservation is polyurethane heat preservation spiral pipe. After pre-treatment such as rust removal, the steel pipe is covered with a layer of polyethylene or steel.

Read more

Spiral steel pipe (SSAW pipe) is a welded pipe made of strip steel coil as raw material, extruded at regular temperature, and welded by automatic double-wire double-sided submerged arc welding process. The spiral steel pipe sends the strip steel into the welded pipe unit, and after rolling by multiple rollers, the strip steel is gradually rolled up to form a circular tube blank with an opening gap.

Read more

The vacuum heat treatment of steel pipes (such as seamless pipes and welded pipes) is a new heat treatment technology that combines vacuum technology and heat treatment technology. The vacuum environment in which vacuum heat treatment is located refers to the atmosphere environment below one atmospheric pressure, including low vacuum, medium vacuum, high vacuum and ultra-high vacuum.

Read more

Hydraulic steel pipes are basically divided into fluid pipes and oil steel tubes used in hydraulic systems, also known as honing pipes, and cold drawn or cold rolled seamless steel pipes also include hydraulic steel pipes.

Read more