The application of steel pipes in marine engineering can be roughly classified into three types:

Read more

In order to slow down and prevent the corrosion and depreciation of steel pipes under the chemical and electrochemical action of internal and external media or due to the metabolism of microorganisms, it is necessary to do a good job of anti-corrosion of pipelines. In addition to the corrosion protection technology for the conveying medium, most steel pipes for conveying oil and natural gas are in a relatively complex soil environment, and the conveyed medium is also corrosive, so the inner and outer walls of the pipeline are likely to corrode.

Read more

Steel is widely used and has a variety of varieties. According to the different cross-sectional shapes, steel is generally divided into four categories: profiles, plates, pipes and metal products, and can be divided into heavy rails, light rails, large steels, medium steels, small steels, and steel cold-formed steels. , High-quality section steel, wire rod, medium and thick steel plate, thin steel plate, silicon steel sheet for electrical purposes, strip steel, seamless steel pipe, welded steel pipe, metal products and other varieties.

Read more

Passivation is due to the interaction between the metal and the oxidizing properties, and a very thin, dense, good covering performance, and a passivation film firmly adsorbed on the metal surface are formed on the metal surface. This film exists in phases, usually compounds of oxidized metals. It plays the role of completely separating the metal from the corrosive medium, preventing the metal from contacting the corrosive medium, so that the metal basically stops dissolving and forms a passive state to prevent corrosion.

Read more

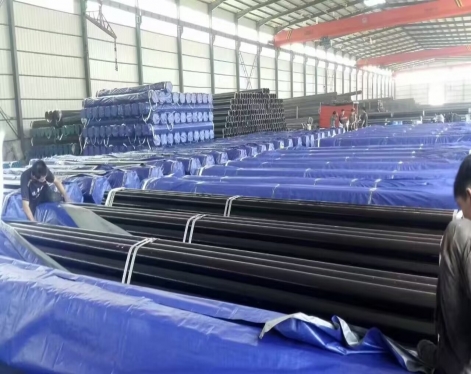

Anti-corrosion steel pipe base materials include spiral pipes, straight seam pipes, seamless pipes, etc. Widely used in pipeline engineering fields such as long-distance water transmission, petroleum, chemical industry, natural gas, thermal power, sewage treatment, water source, bridge, steel structure, marine water transportation piling, etc.

Read more

Electric resistance welded steel pipes, referred to as ERW pipes, have many advantages such as high productivity, low cost, high dimensional accuracy and beautiful appearance. In recent years, countries are actively researching the use of ERW steel pipes instead of seamless steel pipes and spiral seam welded steel pipes.

Read more