Spiral seam submerged arc welded steel pipe (SSAW) refers to a metal pipe with a spiral seam welded by submerged arc welding process. Widely used in water supply engineering, petrochemical industry (such as octg casing), chemical industry, electric power industry, agricultural irrigation, urban construction,

Read more

The main purpose of alloy steel pipe is to be used in high-pressure and high-temperature pipelines and equipment such as power plants, nuclear power plants, high-pressure boilers, high-temperature superheaters and reheaters. It is made of high-quality carbon steel, alloy structural steel and stainless heat-resistant steel.

Read more

Seamless steel pipe is an important type of steel pipe in production and life, and is an important and durable steel in steel pipes. Seamless steel pipes also encounter bending deformation during use. When the seamless steel pipe is bent and deformed, as long as it can be corrected, the seamless steel pipe can continue to be used, otherwise the seamless steel pipe will affect its use. The curvature of the seamless steel pipe can also be controlled, and it should be controlled from the following aspects:

Read more

Fluid pipes are pipes (mostly seamless steel pipes) that are specially used to transport media with fluid properties. The media with fluid properties, in addition to liquid media such as water, oil, solution, etc., solid media such as cement, grain, coal powder, etc., can also flow under certain conditions. Fluid pipes can be made of steel, non-ferrous metals such as copper and titanium, or even non-metallic materials such as plastics.

Read more

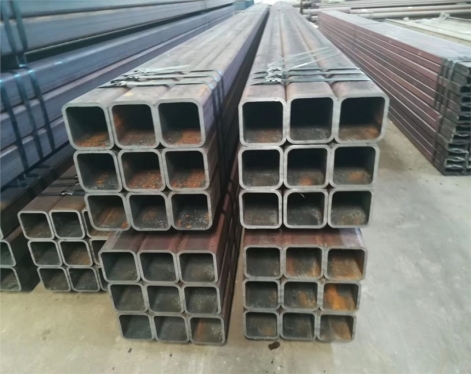

Special-shaped seamless steel pipe is a general term for seamless steel pipes with cross-sectional shapes other than round pipes. Special-shaped seamless steel pipes are widely used in various structural parts, tools and mechanical parts. Compared with round pipes, special-shaped pipes generally have a larger moment of inertia and section modulus, and have greater bending and torsion resistance, which can greatly reduce the structural weight and save steel.

Read more

Steel pipes have a hollow section whose length is much greater than the diameter or circumference of steel. According to the cross-sectional shape, it is divided into round, square, rectangular and special-shaped steel pipes.

Read more