In the oil and gas extraction industry, two types of pipelines are indispensable: tubing and casing. These two types of pipelines play a crucial role in the extraction process. Their respective pressure ratings and pressure differences are key factors determining the safe operation of oilfield equipment and are also important conditions for the effective extraction of oil and gas.

First, let's explain what tubing is. As the name suggests, tubing is used to transport oil. However, in the oil extraction industry, its role goes far beyond that. Tubing is a type of deep-well tubing, and its main responsibility is to transport liquids, gases, and mixtures from the bottom of the well to the surface during drilling, completion, and other operations in oil and gas wells. This means that tubing needs to withstand high pressure from underground; therefore, its design and production must ensure sufficient safety factors to prevent safety problems during actual operation.

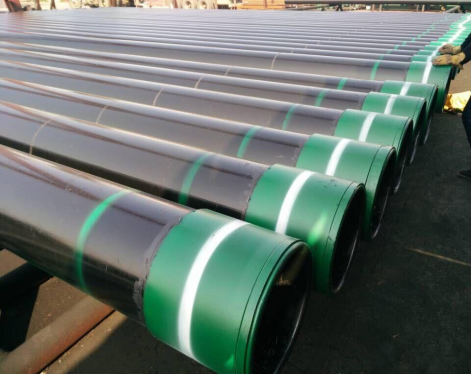

Next, let's understand casing. Casing is also a type of steel pipe, but its main purpose is to stabilize the borehole wall of oil or gas wells, preventing wellbore collapse, and also providing protection for oil and gas extraction. This necessitates that the design and manufacturing of casing must consider its safety factor under ultimate pressure to ensure its safety and stability during actual operation.

Comparing tubing and casing, we find significant differences in their pressure ratings and specific pressures. Generally speaking, because tubing needs to withstand high-pressure oil and gas from underground, it typically needs to withstand higher pressures than casing. On the other hand, while casing also withstands some pressure, its primary function is to stabilize and protect the wellbore, so its pressure rating is usually lower than that of tubing.

Functions of Tubing and Casing Pressure

Casing, installed during drilling and completion, supports the wellbore, isolates formations, and protects the structure. Cemented in place, it withstands long-term formation and annular pressures with relative stability. Unusual readings may indicate sealing issues or formation problems.

Tubing, used during production, transports fluids to the surface and experiences higher, more dynamic pressures from flow, friction, and temperature changes. Packers separate tubing and casing, keeping their pressures independent.

The following table highlights the key differences between tubing and casing pressures:

| Aspect | Tubing (Tubing) | Casing (Casing) |

| Primary Function | Transport oil and gas | Support wellbore and isolate formations |

| Pressure Source | Fluid flow, throttling, friction | Formation pressure, gas migration, injection pressure |

| Pressure Variation | Dynamic, frequent fluctuations | Relatively stable, slow changes |

| Pressure Level | Generally higher | Usually lower but may increase under abnormal conditions |

| Safety Focus | Production efficiency, wellhead safety | Wellbore integrity, annular seal effectiveness |

| Design Standard | API 5CT, wellhead pressure control | Casing strength checks, resistance to collapse and tension |

Why Tubing Pressure Is Usually Higher?

Tubing pressure is generally higher because the fluid inside directly carries reservoir energy or mechanical pump pressure to the surface. In contrast, the casing annulus typically does not transport fluids and maintains a lower, more stable pressure. Understanding this difference is crucial for monitoring well performance and avoiding equipment overpressure or operational disruptions.

In short, the design and manufacturing of both tubing and casing must fully consider their respective operating environments and pressure characteristics to ensure their safe and efficient operation during oil and gas extraction. By understanding and comparing the pressures of tubing and casing, we can gain a deeper understanding of their important roles and requirements in oil and gas extraction, providing valuable reference for our selection and use.