Among the common problems of seamless pipes, wall thickness difference and eccentricity take the first place. In fact, wall thickness difference and eccentricity are the same thing. As the name suggests, it is the difference between the maximum wall thickness and the minimum wall thickness. But how much of this deviation will not affect the customer's later processing? If the wall thickness deviation is too large, what will be the impact on the customer's finished pipe?

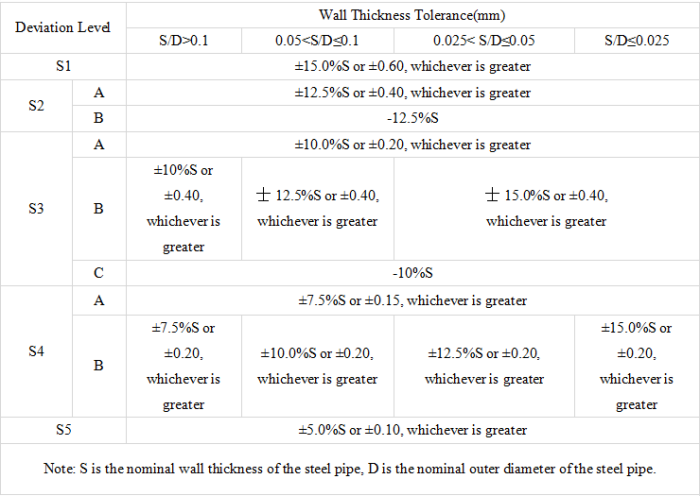

What is the allowable deviation of the seamless pipe wall thickness? According to national regulations, as shown in the figure below:

According to the above national standards for the allowable deviation of wall thickness of seamless pipes, for example:

What is the allowable deviation of the wall thickness of the 25*5 seamless pipe?

Answer: The allowable deviation of the wall thickness of the 25*5 seamless pipe is 0.5-0.625mm.

The uneven thickness of the eccentric will affect the production cost. In some precision machining machinery equipment and hydraulic pipe applications, wall thickness deviation is a very important indicator. Because the eccentricity of the seamless pipe will involve a problem of processing volume, the size of the processing volume directly affects the size of the production cost. If the eccentricity is too large, it cannot be processed to the finished product size required by the customer, resulting in the whole batch of seamless pipes directly becoming waste products, that is, Increased production costs for customers can also lead to delays in delivery. Therefore, customers with wall thickness difference requirements should pay special attention to the detection of steel pipe wall thickness difference when purchasing seamless pipes.

Seamless pipes are made of steel ingots or solid tube blanks through perforation into capillary pipes, which are then hot-rolled, cold-rolled or cold-drawn. According to its production process, it can be divided into two types: cold-drawing and hot-rolling. The outer diameter of hot-rolled seamless pipes is generally greater than 32mm, and the wall thickness is 2.5-200mm. The outer diameter of cold-rolled seamless pipes can reach 6mm and the wall thickness can reach 0.25mm. The outer diameter of the thin-walled pipe can reach 5mm and the wall thickness is less than 0.25mm, and the accuracy of cold-rolled seamless pipes sizes is higher than that of hot-rolled seamless pipes.