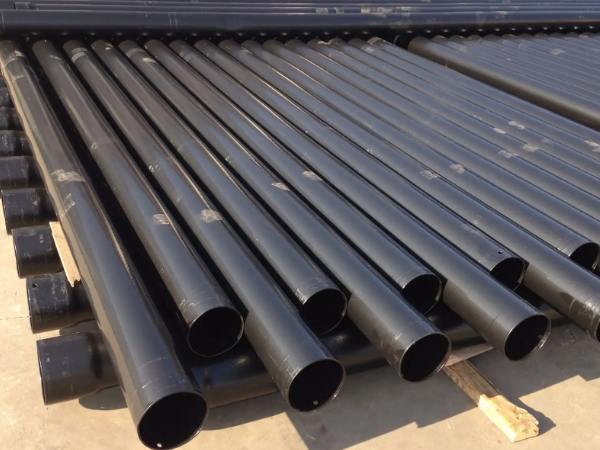

Seamless black steel pipe refers to a steel pipe that is perforated from a whole round steel and has no welds on the surface. Seamless black steel pipe has the advantages of high pressure resistance and good toughness, which determines that it has a wide range of industrial applications, such as widely used in chemical and petroleum industries.

Seamless black steel pipes for chemical and petroleum industries need to be degreased according to special requirements. The purpose of degreasing is to avoid handling degreased or stored materials where grease or organics could cause an explosion, and to avoid mixing of stored oils and organic materials. In order to ensure the activity of the degreasing catalyst, the content of grease can also be controlled. In addition, degreasing controls oil and organic content to ensure product purity. Regardless of the advantages of seamless black steel pipes, they must be degreased section by section after installation. If the seamless black steel pipe cannot be disassembled, it should be degreased before installation. For steel pipes with obvious oil stains or severe corrosion, they should be cleaned by steam blowing, sandblasting or other methods before degreasing.

Seamless black steel pipes can be degreased with organic solvents (such as dichloroethylene, trichloroethylene, solvents, benzene, carbon tetrachloride, industrial alcohol, acetone, etc.), concentrated nitric acid or lye. Industrial dichloroethane is suitable for metal degreasing. Industrial carbon tetrachloride is suitable for degreasing of ferrous and non-metallic parts. Trichloroethylene is suitable for degreasing metal and non-ferrous metal parts, and 88% concentrated nitric acid is suitable for degreasing part of concentrated nitric acid device pipe parts and ceramic rings.

When the outer surface of the seamless black steel pipe is covered with dirt, the dirt should be removed with water first and dried naturally. Then wipe with a dry cloth dampened with degreaser and let dry. When degreasing seamless black steel pipe, one end of the pipe can be tightly cork or closed by other means. Put the steel pipe in a flat and clean place with sleepers or workbench soaked for 60-80min, and rotate it every 20min. Valves, gaskets and other accessories should also be pickled separately, degreased and degreasing.

Seamless black steel pipes for chemical and petroleum industries need to be degreased according to special requirements. The purpose of degreasing is to avoid handling degreased or stored materials where grease or organics could cause an explosion, and to avoid mixing of stored oils and organic materials. In order to ensure the activity of the degreasing catalyst, the content of grease can also be controlled. In addition, degreasing controls oil and organic content to ensure product purity. Regardless of the advantages of seamless black steel pipes, they must be degreased section by section after installation. If the seamless black steel pipe cannot be disassembled, it should be degreased before installation. For steel pipes with obvious oil stains or severe corrosion, they should be cleaned by steam blowing, sandblasting or other methods before degreasing.

Seamless black steel pipes can be degreased with organic solvents (such as dichloroethylene, trichloroethylene, solvents, benzene, carbon tetrachloride, industrial alcohol, acetone, etc.), concentrated nitric acid or lye. Industrial dichloroethane is suitable for metal degreasing. Industrial carbon tetrachloride is suitable for degreasing of ferrous and non-metallic parts. Trichloroethylene is suitable for degreasing metal and non-ferrous metal parts, and 88% concentrated nitric acid is suitable for degreasing part of concentrated nitric acid device pipe parts and ceramic rings.

When the outer surface of the seamless black steel pipe is covered with dirt, the dirt should be removed with water first and dried naturally. Then wipe with a dry cloth dampened with degreaser and let dry. When degreasing seamless black steel pipe, one end of the pipe can be tightly cork or closed by other means. Put the steel pipe in a flat and clean place with sleepers or workbench soaked for 60-80min, and rotate it every 20min. Valves, gaskets and other accessories should also be pickled separately, degreased and degreasing.