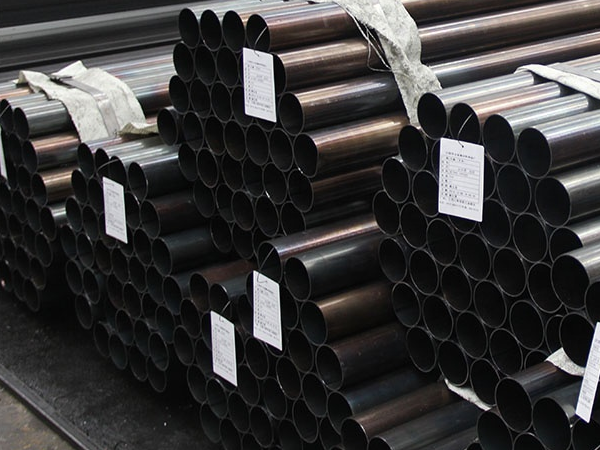

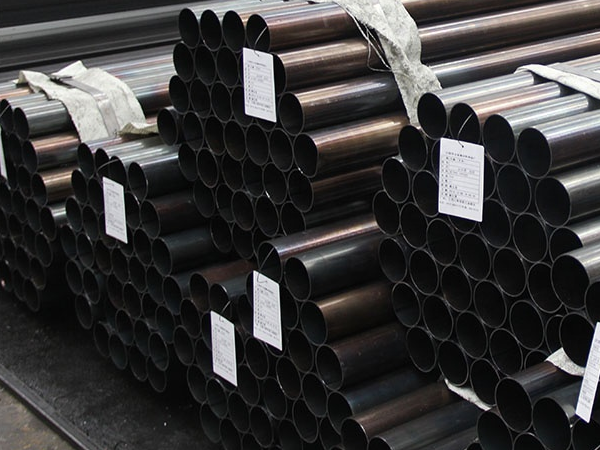

Black steel seamless pipe is a steel pipe that is perforated from a whole round steel and has no welds on the surface. Bending degree means that the steel pipe is curved in the length direction, and its curve degree is expressed by numbers. The curvature specified by the standard is generally divided into the following two types:

1) Local bending degree: measure the bending part of the steel pipe with a one-meter-long ruler, and measure its chord height in mm, which is the local bending degree value, the unit is mm/m, and the expression method is 2.5 mm/m. Suitable for measuring the curvature of tube ends.

2) The total bending degree of the whole length: Use a thin rope to tighten from both ends of the pipe, measure the chord height mm at the bend of the steel pipe, and then convert it into a percentage of the length in meters, which is the full-length bending of the steel pipe in the length direction.

For example: the length of the steel pipe is 10m, and the measured maximum chord height is 30mm, then the bending degree of the whole length of the pipe should be:

0.03/10m*100%=0.3%

The wall thickness of black steel seamless pipe is uneven: the wall thickness of the steel pipe cannot be the same everywhere, and there is uneven wall thickness in its cross section and longitudinal pipe body. In order to control this unevenness, some steel pipe specifications stipulate the allowable indicators of uneven wall thickness, and the general regulations generally do not exceed 80% of the wall thickness tolerance (executed after negotiation between the supplier and the buyer).

How to measure the bending degree of black steel seamless pipe?

With thin steel wire or string, attach the two ends of the bent side of the steel pipe. Tighten the wire rope, and use a steel ruler to measure the maximum distance from the bend of the steel pipe to the wire rope. The ratio of the maximum distance value to the length of the steel pipe is the curvature of the steel pipe.

The bending degree of black steel seamless pipe:

The bending degree of black steel seamless pipe with thickness <15mm shall not be greater than 1.5mm/m

The bending degree of black steel seamless pipe with wall thickness >15mm~30mm shall not be greater than 2.0mm/m

The bending degree of black steel seamless pipe with wall thickness > 30mm or outer diameter ≥ 351mm shall not be greater than 3.0mm/m

Out of tolerance: the seamless pipe specification exceeds the allowable deviation of the national standard. The deviation may be "positive" or "negative", and it is rare that both "positive and negative" deviations are out of line in the same batch of steel pipes. There is a phenomenon of unequal outer diameters on the cross section of seamless steel pipes, that is, there are outer diameters and small outer diameters that are not necessarily perpendicular to each other, and the difference between the outer diameter and the small outer diameter is called the ovality (or not roundness). In order to control the ovality, some seamless steel pipes specify the allowable index of ovality, which is generally specified as not exceeding 80% of the outer diameter tolerance (executed after negotiation between the supplier and the buyer).

1) Local bending degree: measure the bending part of the steel pipe with a one-meter-long ruler, and measure its chord height in mm, which is the local bending degree value, the unit is mm/m, and the expression method is 2.5 mm/m. Suitable for measuring the curvature of tube ends.

2) The total bending degree of the whole length: Use a thin rope to tighten from both ends of the pipe, measure the chord height mm at the bend of the steel pipe, and then convert it into a percentage of the length in meters, which is the full-length bending of the steel pipe in the length direction.

For example: the length of the steel pipe is 10m, and the measured maximum chord height is 30mm, then the bending degree of the whole length of the pipe should be:

0.03/10m*100%=0.3%

The wall thickness of black steel seamless pipe is uneven: the wall thickness of the steel pipe cannot be the same everywhere, and there is uneven wall thickness in its cross section and longitudinal pipe body. In order to control this unevenness, some steel pipe specifications stipulate the allowable indicators of uneven wall thickness, and the general regulations generally do not exceed 80% of the wall thickness tolerance (executed after negotiation between the supplier and the buyer).

How to measure the bending degree of black steel seamless pipe?

With thin steel wire or string, attach the two ends of the bent side of the steel pipe. Tighten the wire rope, and use a steel ruler to measure the maximum distance from the bend of the steel pipe to the wire rope. The ratio of the maximum distance value to the length of the steel pipe is the curvature of the steel pipe.

The bending degree of black steel seamless pipe:

The bending degree of black steel seamless pipe with thickness <15mm shall not be greater than 1.5mm/m

The bending degree of black steel seamless pipe with wall thickness >15mm~30mm shall not be greater than 2.0mm/m

The bending degree of black steel seamless pipe with wall thickness > 30mm or outer diameter ≥ 351mm shall not be greater than 3.0mm/m

Out of tolerance: the seamless pipe specification exceeds the allowable deviation of the national standard. The deviation may be "positive" or "negative", and it is rare that both "positive and negative" deviations are out of line in the same batch of steel pipes. There is a phenomenon of unequal outer diameters on the cross section of seamless steel pipes, that is, there are outer diameters and small outer diameters that are not necessarily perpendicular to each other, and the difference between the outer diameter and the small outer diameter is called the ovality (or not roundness). In order to control the ovality, some seamless steel pipes specify the allowable index of ovality, which is generally specified as not exceeding 80% of the outer diameter tolerance (executed after negotiation between the supplier and the buyer).