There are significant differences between boiler tubes and ordinary steel tubes in terms of materials, manufacturing processes, performance requirements, and application areas. The following is a detailed analysis of the differences between boiler tubes and ordinary steel tubes from multiple dimensions.

Material composition: boiler tube vs ordinary steel tube

Boiler tubes and ordinary steel pipes differ in material composition. Boiler tubes are usually made of high-quality carbon steel, alloy steel or stainless steel, which have high resistance to high temperature, pressure and corrosion. Common boiler tube materials include 20G, 15CrMo, 12Cr1MoV, etc. The chemical composition of these materials is strictly controlled to ensure their stability under high temperature and high pressure environments.

The material composition of ordinary steel tubes is relatively wide, which can be low carbon steel, medium carbon steel or high carbon steel, depending on its application scenario. The material selection of ordinary steel tubes considers cost and economy more than performance requirements under extreme conditions.

Manufacturing process: boiler tube vs ordinary steel tube

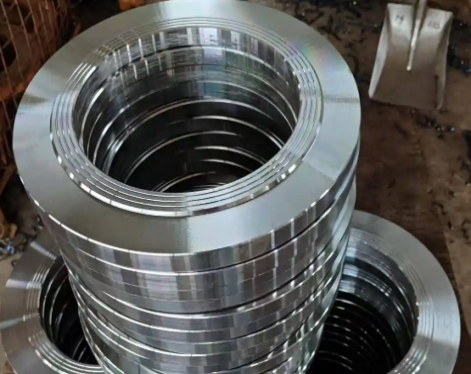

The manufacturing process of boiler tubes is more complex and strict than that of ordinary steel tubes. The production of boiler tubes usually adopts seamless steel tube manufacturing process, including hot rolling, cold drawing, heat treatment and other steps. The dimensional accuracy, surface quality and internal structure of the steel tube need to be strictly controlled during the manufacturing process to ensure its reliability under high temperature and high pressure environment.

The manufacturing process of ordinary steel tubes is relatively simple, and can adopt seamless steel tube or welded steel tube process. Welded steel tubes are usually manufactured by high-frequency welding or submerged arc welding process, which is lower in cost, but the performance requirements are not as strict as boiler tubes.

Performance requirements: boiler tube vs ordinary steel tube

Boiler tubes need to withstand extreme conditions of high temperature and high pressure during use, so their performance requirements are very high. Boiler tubes must have the following characteristics:

High temperature resistance: When boiler tubes work in high temperature environments, the material should maintain good strength and toughness to avoid creep, oxidation or thermal fatigue.

Pressure resistance: Boiler tubes need to withstand high internal pressure, so they must have sufficient compressive strength and burst resistance.

Corrosion resistance: Boiler tubes may be exposed to corrosive media such as water vapor and flue gas during operation, so they need to have good corrosion resistance.

Dimensional accuracy and surface quality: The dimensional accuracy and surface quality of boiler tubes directly affect their sealing and service life, so high requirements are required.

The performance requirements of ordinary steel tubes are relatively low, and they are mainly used to transport fluids, gases or as structural materials. Ordinary steel tubes need to have certain strength and toughness, but their high temperature resistance, pressure resistance and corrosion resistance requirements are much lower than boiler tubes.

Application areas: boiler tube vs ordinary steel tube

Boiler tubes are mainly used in boiler equipment, including power station boilers, industrial boilers, waste heat boilers, etc. Boiler tubes play an important role in boilers and are used to manufacture key components such as superheaters, reheaters, economizers, water walls, etc. These components work under high temperature and high pressure environments and are directly related to the safety and efficiency of the boiler.

Ordinary steel tubes are widely used in construction, machinery manufacturing, petrochemical industry, natural gas transportation, water supply and drainage, etc. Ordinary steel tubes are mainly used to transport fluids and gases or as structural support materials. Their use environment is relatively mild and their performance requirements are relatively low.

Testing and standards: boiler tube vs ordinary steel tube

The production and use of boiler tubes must comply with strict national standards and industry specifications. For example, China's boiler tube standards include GB 5310 "Seamless Steel Tubes for High-Pressure Boilers" and GB 3087 "Seamless Steel Tubes for Low- and Medium-Pressure Boilers". These standards provide detailed regulations on the materials, manufacturing processes, performance indicators, and testing methods of boiler tubes.

The standards for ordinary steel tubes are relatively loose, and common standards include GB/T 8163 "Seamless Steel Pipes for Transporting Fluids", GB/T 3091 "Welded Steel Pipes for Transporting Low-Pressure Fluids", etc. These standards have lower performance requirements for ordinary steel tubes, and the inspection items are relatively simple.

Service life and maintenance: boiler tube vs ordinary steel tube

Boiler tubes work under high temperature and high pressure environment and are easily affected by oxidation, corrosion, creep and other factors. Therefore, their service life is relatively short and they need regular inspection and maintenance. The replacement and maintenance costs of boiler tubes are high, which is directly related to the safety and economy of boiler equipment.

Ordinary steel tubes have a long service life and low maintenance costs. Under normal use conditions, ordinary steel tubes can work stably for a long time without frequent replacement or maintenance.

Price and cost: boiler tube vs ordinary steel tube

Due to the high standards of boiler tubes in terms of materials, manufacturing processes, performance requirements, etc., their production costs and prices are usually higher than ordinary steel tubes. The production of boiler tubes requires high-quality raw materials and complex manufacturing processes, so the price is higher.

Ordinary steel tubes have low production costs and are relatively cheap. Ordinary steel tubes have simple production processes and a wide range of raw material choices, so their prices are more competitive.

Conclusion

There are significant differences between boiler tubes and ordinary steel tubes in terms of materials, manufacturing processes, performance requirements, and application areas. Boiler tubes are mainly used in boiler equipment under high temperature and high pressure environments. They have extremely high requirements on the material's high temperature resistance, pressure resistance, and corrosion resistance. The manufacturing process is complex and the price is relatively high. Ordinary steel tubes are widely used in construction, machinery manufacturing, petrochemical and other fields. They have relatively low performance requirements and are more economical in production costs and prices.

In practical applications, the choice of boiler tubes or ordinary steel tubes should be determined based on the specific use environment and performance requirements. Although boiler tubes are more expensive, they have irreplaceable advantages in high temperature and high pressure environments; ordinary steel tubes have more advantages in terms of economy and versatility.

Read more: Maintenance and Selection of Boiler Tubes

Material composition: boiler tube vs ordinary steel tube

Boiler tubes and ordinary steel pipes differ in material composition. Boiler tubes are usually made of high-quality carbon steel, alloy steel or stainless steel, which have high resistance to high temperature, pressure and corrosion. Common boiler tube materials include 20G, 15CrMo, 12Cr1MoV, etc. The chemical composition of these materials is strictly controlled to ensure their stability under high temperature and high pressure environments.

The material composition of ordinary steel tubes is relatively wide, which can be low carbon steel, medium carbon steel or high carbon steel, depending on its application scenario. The material selection of ordinary steel tubes considers cost and economy more than performance requirements under extreme conditions.

Manufacturing process: boiler tube vs ordinary steel tube

The manufacturing process of boiler tubes is more complex and strict than that of ordinary steel tubes. The production of boiler tubes usually adopts seamless steel tube manufacturing process, including hot rolling, cold drawing, heat treatment and other steps. The dimensional accuracy, surface quality and internal structure of the steel tube need to be strictly controlled during the manufacturing process to ensure its reliability under high temperature and high pressure environment.

The manufacturing process of ordinary steel tubes is relatively simple, and can adopt seamless steel tube or welded steel tube process. Welded steel tubes are usually manufactured by high-frequency welding or submerged arc welding process, which is lower in cost, but the performance requirements are not as strict as boiler tubes.

Performance requirements: boiler tube vs ordinary steel tube

Boiler tubes need to withstand extreme conditions of high temperature and high pressure during use, so their performance requirements are very high. Boiler tubes must have the following characteristics:

High temperature resistance: When boiler tubes work in high temperature environments, the material should maintain good strength and toughness to avoid creep, oxidation or thermal fatigue.

Pressure resistance: Boiler tubes need to withstand high internal pressure, so they must have sufficient compressive strength and burst resistance.

Corrosion resistance: Boiler tubes may be exposed to corrosive media such as water vapor and flue gas during operation, so they need to have good corrosion resistance.

Dimensional accuracy and surface quality: The dimensional accuracy and surface quality of boiler tubes directly affect their sealing and service life, so high requirements are required.

The performance requirements of ordinary steel tubes are relatively low, and they are mainly used to transport fluids, gases or as structural materials. Ordinary steel tubes need to have certain strength and toughness, but their high temperature resistance, pressure resistance and corrosion resistance requirements are much lower than boiler tubes.

Application areas: boiler tube vs ordinary steel tube

Boiler tubes are mainly used in boiler equipment, including power station boilers, industrial boilers, waste heat boilers, etc. Boiler tubes play an important role in boilers and are used to manufacture key components such as superheaters, reheaters, economizers, water walls, etc. These components work under high temperature and high pressure environments and are directly related to the safety and efficiency of the boiler.

Ordinary steel tubes are widely used in construction, machinery manufacturing, petrochemical industry, natural gas transportation, water supply and drainage, etc. Ordinary steel tubes are mainly used to transport fluids and gases or as structural support materials. Their use environment is relatively mild and their performance requirements are relatively low.

Testing and standards: boiler tube vs ordinary steel tube

The production and use of boiler tubes must comply with strict national standards and industry specifications. For example, China's boiler tube standards include GB 5310 "Seamless Steel Tubes for High-Pressure Boilers" and GB 3087 "Seamless Steel Tubes for Low- and Medium-Pressure Boilers". These standards provide detailed regulations on the materials, manufacturing processes, performance indicators, and testing methods of boiler tubes.

The standards for ordinary steel tubes are relatively loose, and common standards include GB/T 8163 "Seamless Steel Pipes for Transporting Fluids", GB/T 3091 "Welded Steel Pipes for Transporting Low-Pressure Fluids", etc. These standards have lower performance requirements for ordinary steel tubes, and the inspection items are relatively simple.

Service life and maintenance: boiler tube vs ordinary steel tube

Boiler tubes work under high temperature and high pressure environment and are easily affected by oxidation, corrosion, creep and other factors. Therefore, their service life is relatively short and they need regular inspection and maintenance. The replacement and maintenance costs of boiler tubes are high, which is directly related to the safety and economy of boiler equipment.

Ordinary steel tubes have a long service life and low maintenance costs. Under normal use conditions, ordinary steel tubes can work stably for a long time without frequent replacement or maintenance.

Price and cost: boiler tube vs ordinary steel tube

Due to the high standards of boiler tubes in terms of materials, manufacturing processes, performance requirements, etc., their production costs and prices are usually higher than ordinary steel tubes. The production of boiler tubes requires high-quality raw materials and complex manufacturing processes, so the price is higher.

Ordinary steel tubes have low production costs and are relatively cheap. Ordinary steel tubes have simple production processes and a wide range of raw material choices, so their prices are more competitive.

Conclusion

There are significant differences between boiler tubes and ordinary steel tubes in terms of materials, manufacturing processes, performance requirements, and application areas. Boiler tubes are mainly used in boiler equipment under high temperature and high pressure environments. They have extremely high requirements on the material's high temperature resistance, pressure resistance, and corrosion resistance. The manufacturing process is complex and the price is relatively high. Ordinary steel tubes are widely used in construction, machinery manufacturing, petrochemical and other fields. They have relatively low performance requirements and are more economical in production costs and prices.

In practical applications, the choice of boiler tubes or ordinary steel tubes should be determined based on the specific use environment and performance requirements. Although boiler tubes are more expensive, they have irreplaceable advantages in high temperature and high pressure environments; ordinary steel tubes have more advantages in terms of economy and versatility.

Read more: Maintenance and Selection of Boiler Tubes