Stainless steel angle steel is a widely used type of stainless steel profile, which has the characteristics of stable structure, corrosion resistance, strong deformation resistance, stable chemical properties, etc. Compared with profiles made of other metal materials, it has incomparable advantages.

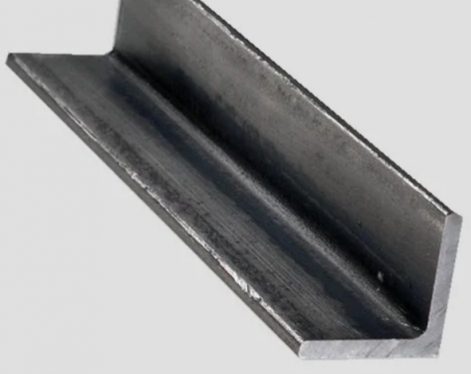

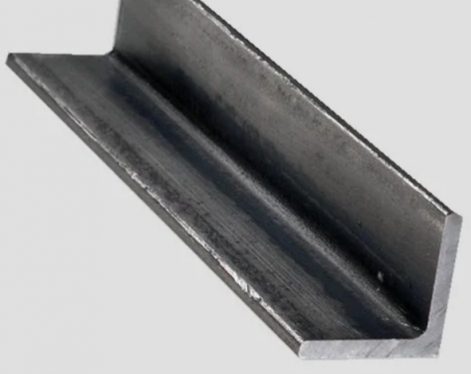

Definition of stainless steel angle steel

Stainless steel angle steel generally refers to a long steel strip made of stainless steel with two sides at right angles. According to the length of the sides, it is divided into equilateral stainless steel angle steel and unequal-sided stainless steel angle steel. The equilateral stainless steel angle steel has two sides of equal width.

Common stainless steel materials for manufacturing stainless steel angle steel

Stainless steel angles can be classified according to their materials. Common types include martensitic stainless steel, ferritic stainless steel, duplex stainless steel, austenitic stainless steel and precipitation hardening stainless steel, etc.

1. Austenitic stainless steel

The output and usage of this type of material occupy the mainstream position of products, accounting for 70.1% of the total amount of stainless steel. It is a very important category of stainless steel. According to the alloy ratio, austenitic stainless steel can be divided into two categories: chromium-nickel steel and iron-chromium-manganese steel. The former uses nickel as the austenitizing element and is the main component of austenitic steel. Considering the production cost, the latter is a nickel-saving steel that uses manganese and nitrogen instead of expensive nickel. Austenitic steel has good corrosion resistance, good comprehensive mechanical properties and processing properties, but its strength and hardness are relatively weak.

2. Ferritic stainless steel

Ferritic stainless steel contains 11%-30% chromium and basically no nickel. It is a nickel-saving steel type and its structure is mainly ferrite when in use. Ferritic stainless steel has higher strength and lower tendency to harden by cold work. It has excellent resistance to local corrosion such as chloride stress corrosion, pitting corrosion, and crevice corrosion. However, it is sensitive to intergranular corrosion and has poor low-temperature toughness.

3. Duplex stainless steel

Traditionally, it is believed that when there is more than 15% ferrite on an austenite matrix, and vice versa, when there is more than 15% austenite on a ferrite matrix, we can call it austenite + ferrite duplex stainless steel. Duplex stainless steel has the advantages of both austenitic steel and ferritic steel.

4. Martensitic stainless steel

Martensitic stainless steel is a type of steel whose properties can be adjusted by heat treatment and has high strength and hardness. Precipitation hardening stainless steel is a steel that is made by precipitating carbides in the steel through heat treatment to increase its strength.

Specifications of common stainless steel angle steels

1. Dimensions

"∠30×30×3" means an equilateral stainless steel angle with a side width of 30 mm and a side thickness of 3 mm. This is expressed in millimeters as side width × side width × side thickness.

2. Model Notation

The model number is the width of the side in centimeters, such as ∠3#. The model number cannot indicate product information with different edge thicknesses in the same model number. Therefore, when customizing the contract, the buyer and seller still need to fill in the edge width and thickness of the stainless steel angle steel in full, rather than using the model number alone, to avoid ambiguity and disputes.

Currently, the common specifications of domestic stainless steel angle steels range from 2 to 20, with the number being based on the length in centimeters of the side. The same angle steel has approximately 2 to 7 different side thicknesses. Imported stainless steel angle steels are marked with the actual dimensions and thickness of both sides and the relevant standards. Generally, large stainless steel angle steels have a side length of more than 12.5 cm, medium-sized stainless steel angle steels are between 12.5 cm and 5 cm, and small stainless steel angle steels are less than 5 cm.

Delivery length of stainless steel angle steel

In addition to indicating stainless steel angle products by edge thickness, in the actual transaction process, it is also necessary to order products according to length. To meet the needs of different application scenarios. The delivery length of stainless steel angle steel is divided into fixed length and multiple length. The fixed length selection range of domestic stainless steel angle steel includes four ranges: 3-9m, 4-12m, 4-19m, and 6-19m according to different specifications. The length selection range of Japanese stainless steel angle steel is 6-15m. The cross-sectional height of unequal stainless steel angle steel is calculated according to the long side width of unequal stainless steel angle steel.

Appearance quality requirements of stainless steel angle steel

Stainless steel angles are generally required not to have defects that are harmful to use, such as delamination, scarring, cracks, etc. The surface quality is specifically stipulated in the standard, and the allowable range of geometric deviation of stainless steel angle steel is also stipulated in the standard, generally including curvature, edge width, edge thickness, top angle, theoretical weight, etc., and it is stipulated that stainless steel angle steel shall not have significant torsion.

Common uses of stainless steel angle steel

Stainless steel angle steel is widely used in various building structures and engineering structures, from civil beams, warehouse shelves, equipment rack bases, to industrial bridges, transmission towers, lifting and transportation machinery, and even military ships, industrial furnaces, reaction towers, and container racks. It can be used to form various load-bearing components according to different structural needs, and can also be used as connecting parts between components. Compared with angle steels made of other materials (such as angle iron), stainless steel angle steels are incomparable in material performance. However, the cost is relatively high, and stainless steel angle steels are not used in all applicable occasions.

Read more: Stainless Steel Angle Steel:Material,Specification,Delivery Length

Definition of stainless steel angle steel

Stainless steel angle steel generally refers to a long steel strip made of stainless steel with two sides at right angles. According to the length of the sides, it is divided into equilateral stainless steel angle steel and unequal-sided stainless steel angle steel. The equilateral stainless steel angle steel has two sides of equal width.

Common stainless steel materials for manufacturing stainless steel angle steel

Stainless steel angles can be classified according to their materials. Common types include martensitic stainless steel, ferritic stainless steel, duplex stainless steel, austenitic stainless steel and precipitation hardening stainless steel, etc.

1. Austenitic stainless steel

The output and usage of this type of material occupy the mainstream position of products, accounting for 70.1% of the total amount of stainless steel. It is a very important category of stainless steel. According to the alloy ratio, austenitic stainless steel can be divided into two categories: chromium-nickel steel and iron-chromium-manganese steel. The former uses nickel as the austenitizing element and is the main component of austenitic steel. Considering the production cost, the latter is a nickel-saving steel that uses manganese and nitrogen instead of expensive nickel. Austenitic steel has good corrosion resistance, good comprehensive mechanical properties and processing properties, but its strength and hardness are relatively weak.

2. Ferritic stainless steel

Ferritic stainless steel contains 11%-30% chromium and basically no nickel. It is a nickel-saving steel type and its structure is mainly ferrite when in use. Ferritic stainless steel has higher strength and lower tendency to harden by cold work. It has excellent resistance to local corrosion such as chloride stress corrosion, pitting corrosion, and crevice corrosion. However, it is sensitive to intergranular corrosion and has poor low-temperature toughness.

3. Duplex stainless steel

Traditionally, it is believed that when there is more than 15% ferrite on an austenite matrix, and vice versa, when there is more than 15% austenite on a ferrite matrix, we can call it austenite + ferrite duplex stainless steel. Duplex stainless steel has the advantages of both austenitic steel and ferritic steel.

4. Martensitic stainless steel

Martensitic stainless steel is a type of steel whose properties can be adjusted by heat treatment and has high strength and hardness. Precipitation hardening stainless steel is a steel that is made by precipitating carbides in the steel through heat treatment to increase its strength.

Specifications of common stainless steel angle steels

1. Dimensions

"∠30×30×3" means an equilateral stainless steel angle with a side width of 30 mm and a side thickness of 3 mm. This is expressed in millimeters as side width × side width × side thickness.

2. Model Notation

The model number is the width of the side in centimeters, such as ∠3#. The model number cannot indicate product information with different edge thicknesses in the same model number. Therefore, when customizing the contract, the buyer and seller still need to fill in the edge width and thickness of the stainless steel angle steel in full, rather than using the model number alone, to avoid ambiguity and disputes.

Currently, the common specifications of domestic stainless steel angle steels range from 2 to 20, with the number being based on the length in centimeters of the side. The same angle steel has approximately 2 to 7 different side thicknesses. Imported stainless steel angle steels are marked with the actual dimensions and thickness of both sides and the relevant standards. Generally, large stainless steel angle steels have a side length of more than 12.5 cm, medium-sized stainless steel angle steels are between 12.5 cm and 5 cm, and small stainless steel angle steels are less than 5 cm.

Delivery length of stainless steel angle steel

In addition to indicating stainless steel angle products by edge thickness, in the actual transaction process, it is also necessary to order products according to length. To meet the needs of different application scenarios. The delivery length of stainless steel angle steel is divided into fixed length and multiple length. The fixed length selection range of domestic stainless steel angle steel includes four ranges: 3-9m, 4-12m, 4-19m, and 6-19m according to different specifications. The length selection range of Japanese stainless steel angle steel is 6-15m. The cross-sectional height of unequal stainless steel angle steel is calculated according to the long side width of unequal stainless steel angle steel.

Appearance quality requirements of stainless steel angle steel

Stainless steel angles are generally required not to have defects that are harmful to use, such as delamination, scarring, cracks, etc. The surface quality is specifically stipulated in the standard, and the allowable range of geometric deviation of stainless steel angle steel is also stipulated in the standard, generally including curvature, edge width, edge thickness, top angle, theoretical weight, etc., and it is stipulated that stainless steel angle steel shall not have significant torsion.

Common uses of stainless steel angle steel

Stainless steel angle steel is widely used in various building structures and engineering structures, from civil beams, warehouse shelves, equipment rack bases, to industrial bridges, transmission towers, lifting and transportation machinery, and even military ships, industrial furnaces, reaction towers, and container racks. It can be used to form various load-bearing components according to different structural needs, and can also be used as connecting parts between components. Compared with angle steels made of other materials (such as angle iron), stainless steel angle steels are incomparable in material performance. However, the cost is relatively high, and stainless steel angle steels are not used in all applicable occasions.

Read more: Stainless Steel Angle Steel:Material,Specification,Delivery Length