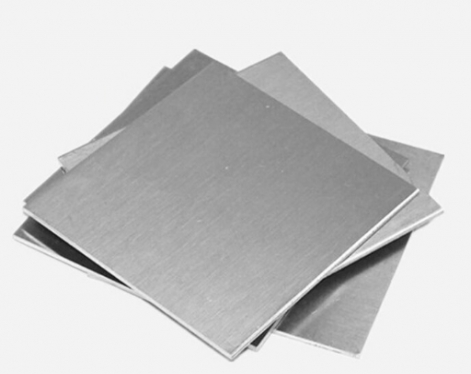

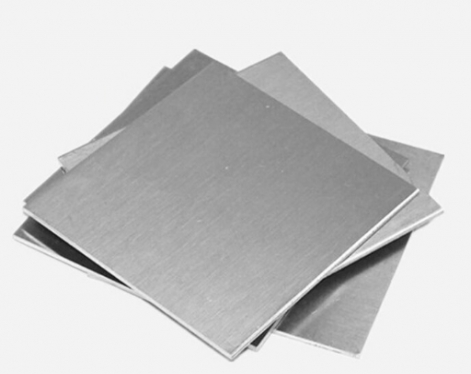

Stainless steel plate is a corrosion-resistant steel based on iron with alloy elements such as chromium, nickel and molybdenum added. A dense oxide film is formed on its surface, which can resist acid and alkali corrosion and rust, and has both strength and toughness. According to the organizational type, it can be divided into austenite (such as 304, 316L), ferrite, martensite, etc. Austenitic stainless steel has the best comprehensive performance and is the most widely used.

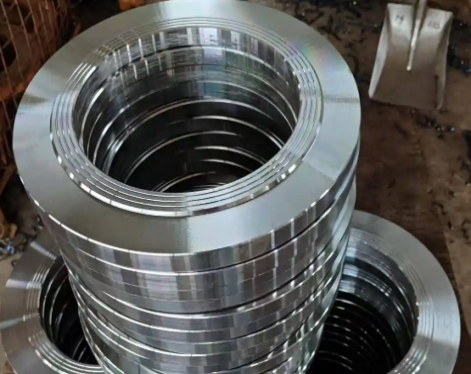

It is widely used in food machinery, chemical equipment, architectural decoration, medical equipment and other fields. It can be made into plates with different thicknesses (0.3-100mm+) and surface accuracy (such as mirror finish, brushed finish) through cold rolling and hot rolling processes to meet diverse needs such as corrosion resistance, wear resistance and aesthetics.

Why does steel change color?

When steel heats up, its internal structure changes. As the temperature rises, the surface of the steel meets the atmosphere and oxidation occurs. The color of the steel surface is not fixed, but is affected by many factors. From the perspective of steel itself, the color change is different due to its different metal composition. Steel with a high carbon content and steel with a low carbon content will have different colors after oxidation under the same conditions.

The composition of the atmosphere is also critical. In an environment with high oxygen content, steel oxidizes faster and the color change is more obvious; Under some special atmospheres, a special oxide film may be formed, presenting a unique color. The influence of temperature and exposure time should not be underestimated. The higher the temperature, the more intense the oxidation reaction and the faster the color change. The longer the exposure time, the deeper the oxidation and the corresponding color change will occur.

Causes of stainless steel plate weld color

When stainless steel plates are welded, pores are created on the surface due to oxidation, through which shielding gas or flux enters. Its purpose is to protect the hot welding area from the influence of atmospheric pressure until the weld is cooled. If the steel mixes with the atmosphere and reacts before the weld bead cools, it can cause color in the weld.

Therefore, it is not just because welding is done at a certain temperature that the weld will have a specific color. Its formation is actually affected by a combination of factors. On stainless steel plates, as long as there is color in the weld or heat-affected zone, it means that an oxide layer has been formed. The darker the color and the thicker the oxide layer, the greater the impact on the corrosion resistance of the stainless steel plate. The color change generally follows the rule from gold to blue to purple.

Relationship between weld color, quality and application

Welds of different colors represent different quality conditions. Generally speaking, a silvery white weld indicates that the welding process conditions are well controlled and the physical and chemical values are optimal; The quality of the golden weld is also acceptable. But when the weld appears colorful, blue or even dark blue, the situation is not optimistic. The colorful welds have partially produced intergranular corrosion and chromium depletion, that is, chromium carbide has been formed, which will cause the stainless steel to lose its original corrosion resistance. The welding quality of blue, dark blue and darker welds is even more difficult to guarantee.

Different industries also have different levels of acceptance of weld color. In industries such as pharmaceuticals, which have extremely high requirements for hygiene and corrosion resistance, any color beyond chrome (close to silvery white) in welds is unacceptable; while in the dairy industry, light blue to dark welds are allowed.

Conclusion

The generation of stainless steel plate weld color is a complex process, which is affected by many factors. The color of the weld is determined by the properties of steel itself, protective measures during welding, various parameters of the welding process, and the needs of different industries. Understanding this knowledge can not only help us judge the quality of welding, but also adjust the welding process in a targeted manner according to the specific requirements of different industries in actual production, thereby improving welding quality and meeting diverse industry needs.

Read more: Annealing Process of Stainless Steel Plates

It is widely used in food machinery, chemical equipment, architectural decoration, medical equipment and other fields. It can be made into plates with different thicknesses (0.3-100mm+) and surface accuracy (such as mirror finish, brushed finish) through cold rolling and hot rolling processes to meet diverse needs such as corrosion resistance, wear resistance and aesthetics.

Why does steel change color?

When steel heats up, its internal structure changes. As the temperature rises, the surface of the steel meets the atmosphere and oxidation occurs. The color of the steel surface is not fixed, but is affected by many factors. From the perspective of steel itself, the color change is different due to its different metal composition. Steel with a high carbon content and steel with a low carbon content will have different colors after oxidation under the same conditions.

The composition of the atmosphere is also critical. In an environment with high oxygen content, steel oxidizes faster and the color change is more obvious; Under some special atmospheres, a special oxide film may be formed, presenting a unique color. The influence of temperature and exposure time should not be underestimated. The higher the temperature, the more intense the oxidation reaction and the faster the color change. The longer the exposure time, the deeper the oxidation and the corresponding color change will occur.

Causes of stainless steel plate weld color

When stainless steel plates are welded, pores are created on the surface due to oxidation, through which shielding gas or flux enters. Its purpose is to protect the hot welding area from the influence of atmospheric pressure until the weld is cooled. If the steel mixes with the atmosphere and reacts before the weld bead cools, it can cause color in the weld.

Therefore, it is not just because welding is done at a certain temperature that the weld will have a specific color. Its formation is actually affected by a combination of factors. On stainless steel plates, as long as there is color in the weld or heat-affected zone, it means that an oxide layer has been formed. The darker the color and the thicker the oxide layer, the greater the impact on the corrosion resistance of the stainless steel plate. The color change generally follows the rule from gold to blue to purple.

Relationship between weld color, quality and application

Welds of different colors represent different quality conditions. Generally speaking, a silvery white weld indicates that the welding process conditions are well controlled and the physical and chemical values are optimal; The quality of the golden weld is also acceptable. But when the weld appears colorful, blue or even dark blue, the situation is not optimistic. The colorful welds have partially produced intergranular corrosion and chromium depletion, that is, chromium carbide has been formed, which will cause the stainless steel to lose its original corrosion resistance. The welding quality of blue, dark blue and darker welds is even more difficult to guarantee.

Different industries also have different levels of acceptance of weld color. In industries such as pharmaceuticals, which have extremely high requirements for hygiene and corrosion resistance, any color beyond chrome (close to silvery white) in welds is unacceptable; while in the dairy industry, light blue to dark welds are allowed.

Conclusion

The generation of stainless steel plate weld color is a complex process, which is affected by many factors. The color of the weld is determined by the properties of steel itself, protective measures during welding, various parameters of the welding process, and the needs of different industries. Understanding this knowledge can not only help us judge the quality of welding, but also adjust the welding process in a targeted manner according to the specific requirements of different industries in actual production, thereby improving welding quality and meeting diverse industry needs.

Read more: Annealing Process of Stainless Steel Plates