During the smelting and rolling (forging) process of carbon steel pipes, steel is lacking due to reasons such as equipment, technology and operation. It mainly includes scars, cracks, shrinkage cavity residues, delamination, white spots, segregation, non-metallic inclusions, loose and banded tissues, etc.

1. Scarring

Metal or non-metal scars on the steel pipe surface that are not welded to the substrate. Some parts are connected to the base body and are tongue-shaped; some are not connected to the base body and are scale-like. The latter sometimes falls off during processing, forming pits. Scabs caused by steelmaking (casting) generally have non-metallic inclusions visible to the naked eye under the scars. The scars caused by steel rolling are generally called "rolling scars", and there is usually only iron oxide scale under the scars.

2. Cracks

There are many names according to the shape and cause of cracks, such as tensile cracks, transverse cracks, cracks, cracks, hairlines, bursts (sound cracks), brittle cracks (straightening cracks), rolling cracks, and shear cracks. From steelmaking, steel rolling to steel deep processing, almost every process has factors that cause cracks.

3. Shrinkage cavity residue

During the solidification process of molten steel, due to volume shrinkage, the core of the steel ingot or continuous casting slab is not fully filled and formed as tubular or scattered holes. Before thermal processing, because the cutting head is too small or the shrinkage cavity is deep, the cutting is not complete, and the remaining part is called shrinkage cavity residue.

Shrinkage cavity residues seriously damage the continuity of the steel pipe, which is a defect that is not allowed to exist in the steel pipe. Cracks will inevitably occur on the billet during rolling (forging). In order to prevent the generation of shrinkage cavity, it is required to correctly design the size of the steel pipe mold and the heat preservation cap, and to use mold powder, heat preservation agent (heating agent) and heat insulation board with excellent performance. Control the shrinkage cavity at the head of the ingot to ensure that it will be cut off when the billet is opened. Control the casting speed not to be too fast and the temperature not to be too high to prevent shrinkage cavity.

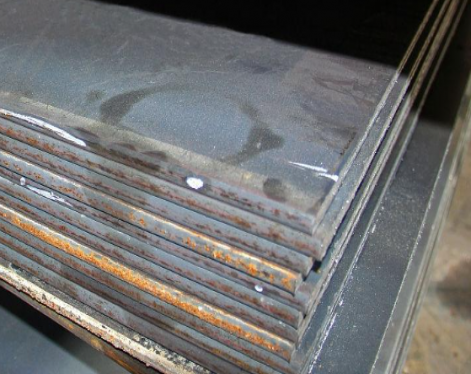

4. Layering

The two-layer structure that does not combine with each other appears on the steel pipe substrate. The delamination is generally parallel to the press-processed surface, and there are black lines on the low-magnification test pieces in the longitudinal and transverse sections. When the delamination is serious, cracks occur, and there are often iron oxide, non-metallic inclusions and serious segregation substances in the cracks.

5. Non-metallic inclusions

Steel contains non-metallic substances that are different in composition from the base metal. It destroys the continuity and isotropy properties of the metal matrix.

6. Loose

The phenomenon that the structure of the hot acid etching test piece of the steel cross section is not dense. On the steel cross-section hot acid etching test piece, there are many pores and small black spots, showing that the structure is not compact. When these pores and small black spots are distributed on the entire test piece, it is called a loose, and the one that is concentrated in the center is called central looseness. .

7. Ribbon tissue

The microstructure of the low-carbon structural steel pipe after thermal processing, the ferrite and pearlite are arranged in parallel along the rolling direction, and are distributed in a band shape, forming a steel band structure.

Precautions

Water cooling is usually used for carbon steel pipe quenching, but for small-sized medium-carbon steel pipes, especially steel pipes with a diameter of 8-12mm, cracks are prone to occur during quenching, which is a relatively complicated problem. The measures taken are to stir the sample rapidly in water during quenching, or use oil cooling to avoid cracks

1. Scarring

Metal or non-metal scars on the steel pipe surface that are not welded to the substrate. Some parts are connected to the base body and are tongue-shaped; some are not connected to the base body and are scale-like. The latter sometimes falls off during processing, forming pits. Scabs caused by steelmaking (casting) generally have non-metallic inclusions visible to the naked eye under the scars. The scars caused by steel rolling are generally called "rolling scars", and there is usually only iron oxide scale under the scars.

2. Cracks

There are many names according to the shape and cause of cracks, such as tensile cracks, transverse cracks, cracks, cracks, hairlines, bursts (sound cracks), brittle cracks (straightening cracks), rolling cracks, and shear cracks. From steelmaking, steel rolling to steel deep processing, almost every process has factors that cause cracks.

3. Shrinkage cavity residue

During the solidification process of molten steel, due to volume shrinkage, the core of the steel ingot or continuous casting slab is not fully filled and formed as tubular or scattered holes. Before thermal processing, because the cutting head is too small or the shrinkage cavity is deep, the cutting is not complete, and the remaining part is called shrinkage cavity residue.

Shrinkage cavity residues seriously damage the continuity of the steel pipe, which is a defect that is not allowed to exist in the steel pipe. Cracks will inevitably occur on the billet during rolling (forging). In order to prevent the generation of shrinkage cavity, it is required to correctly design the size of the steel pipe mold and the heat preservation cap, and to use mold powder, heat preservation agent (heating agent) and heat insulation board with excellent performance. Control the shrinkage cavity at the head of the ingot to ensure that it will be cut off when the billet is opened. Control the casting speed not to be too fast and the temperature not to be too high to prevent shrinkage cavity.

4. Layering

The two-layer structure that does not combine with each other appears on the steel pipe substrate. The delamination is generally parallel to the press-processed surface, and there are black lines on the low-magnification test pieces in the longitudinal and transverse sections. When the delamination is serious, cracks occur, and there are often iron oxide, non-metallic inclusions and serious segregation substances in the cracks.

5. Non-metallic inclusions

Steel contains non-metallic substances that are different in composition from the base metal. It destroys the continuity and isotropy properties of the metal matrix.

6. Loose

The phenomenon that the structure of the hot acid etching test piece of the steel cross section is not dense. On the steel cross-section hot acid etching test piece, there are many pores and small black spots, showing that the structure is not compact. When these pores and small black spots are distributed on the entire test piece, it is called a loose, and the one that is concentrated in the center is called central looseness. .

7. Ribbon tissue

The microstructure of the low-carbon structural steel pipe after thermal processing, the ferrite and pearlite are arranged in parallel along the rolling direction, and are distributed in a band shape, forming a steel band structure.

Precautions

Water cooling is usually used for carbon steel pipe quenching, but for small-sized medium-carbon steel pipes, especially steel pipes with a diameter of 8-12mm, cracks are prone to occur during quenching, which is a relatively complicated problem. The measures taken are to stir the sample rapidly in water during quenching, or use oil cooling to avoid cracks