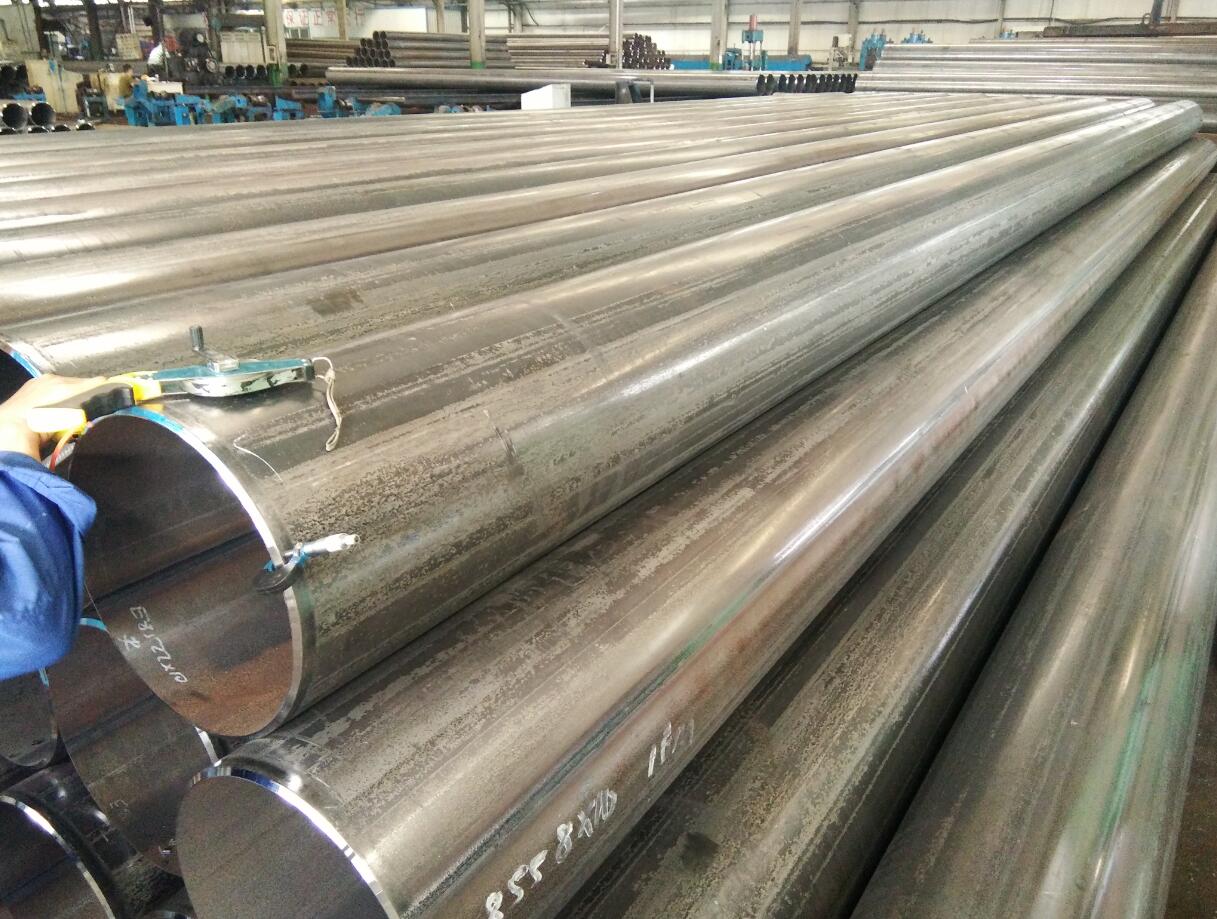

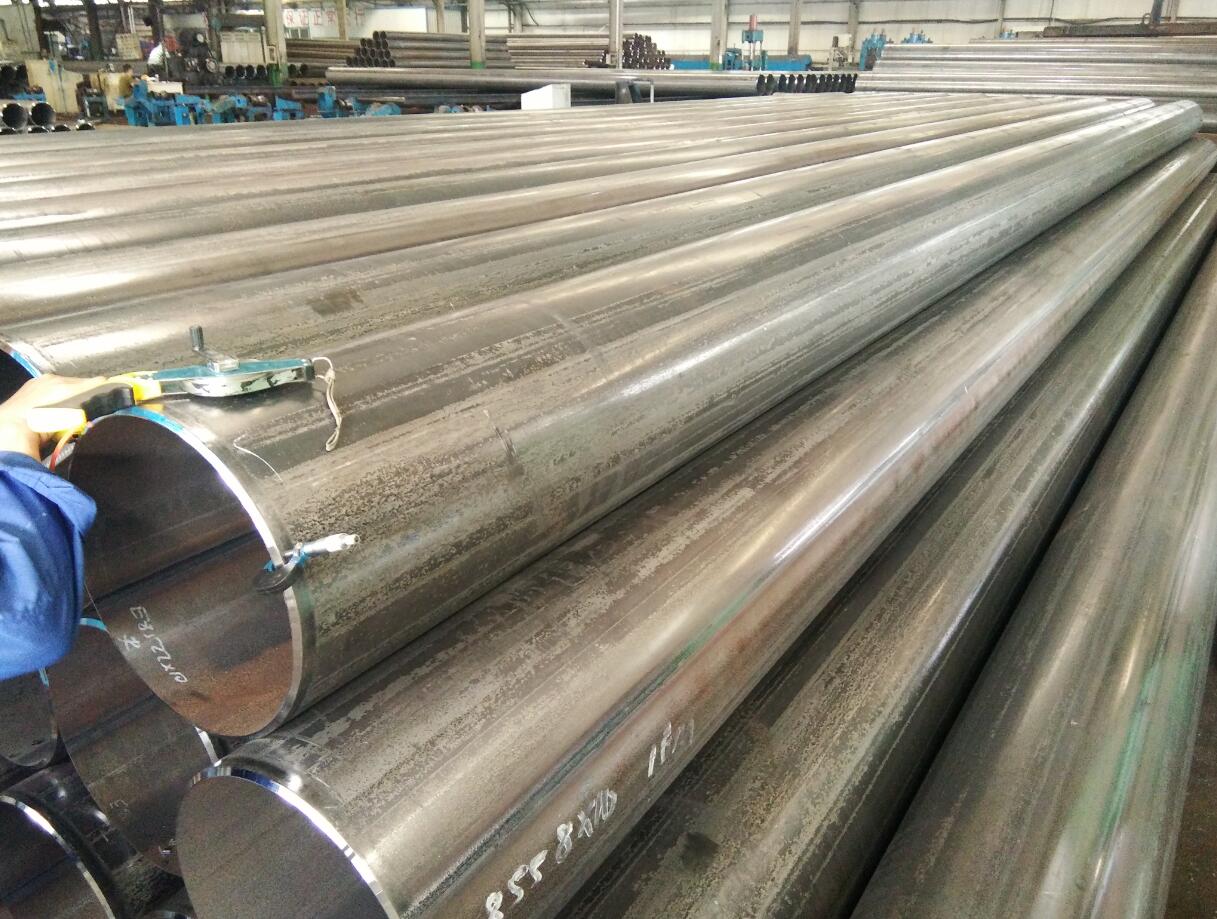

Straight seam steel pipe is a welded steel tube in which the weld seam is parallel to the longitudinal direction of the steel pipe. According to the production process, it can be divided into ERW pipe and LSAW pipe. The production process of straight seam welded pipe is simple, the production efficiency is high, the cost is low, and the development is rapid.

Features of straight seam steel pipe:

1. The steel pipe is a closed section; when the average thickness and cross-sectional area are the same, its exposed surface area is about 50% to 60% of the open section, which is beneficial to prevent corrosion and save coating materials.

2. The geometric characteristics of the pipe section are good, the pipe wall is generally thin, the section material is distributed around the centroid, the section radius of gyration is large, and it has relatively good torsional rigidity. As a compression, compression bending and two-way bending member, its bearing capacity is relatively good, and the straightness and cross-sectional dimension accuracy of cold-formed pipes are better than those of hot-rolled open cross-sections.

3. The appearance is more beautiful, especially the pipe truss composed of steel pipe members, without redundant node connections, and has a strong sense of modernity.

4. In terms of anti-hydrodynamic characteristics, the cross-section of the round pipe is good, and the effect of wind and water flow is greatly reduced. Rectangular tube sections are similar to other open sections in this regard.

5. When necessary, concrete can also be poured in the pipe to form a composite member.

6. Its node connection is suitable for direct welding, which does not need to pass through the gusset plate or other connecting parts, which saves labor and materials.

Disadvantages of straight seam steel pipe:

1. Residual stress caused by uneven cooling. Residual stress is the internal self-equilibrium stress without external force. Hot-rolled steel sections of various cross-sections have this kind of residual stress. Generally, the larger the section size of the steel section, the greater the residual stress. Although the residual stress is self-equilibrium, it still has some influence on the performance of the steel member under the action of external force. For example, it may have adverse effects on deformation, stability, fatigue resistance, etc.

2. After welding, the non-metallic inclusions inside the straight seam steel pipe are pressed into thin sheets, and stratification occurs. Delamination makes the 20# straight seam steel pipe tensile in the thickness direction, and there may be interlaminar tearing when the weld shrinks. The local strain induced by weld shrinkage often reaches several times the yield point strain, which is much larger than the strain caused by the load.

Features of straight seam steel pipe:

1. The steel pipe is a closed section; when the average thickness and cross-sectional area are the same, its exposed surface area is about 50% to 60% of the open section, which is beneficial to prevent corrosion and save coating materials.

2. The geometric characteristics of the pipe section are good, the pipe wall is generally thin, the section material is distributed around the centroid, the section radius of gyration is large, and it has relatively good torsional rigidity. As a compression, compression bending and two-way bending member, its bearing capacity is relatively good, and the straightness and cross-sectional dimension accuracy of cold-formed pipes are better than those of hot-rolled open cross-sections.

3. The appearance is more beautiful, especially the pipe truss composed of steel pipe members, without redundant node connections, and has a strong sense of modernity.

4. In terms of anti-hydrodynamic characteristics, the cross-section of the round pipe is good, and the effect of wind and water flow is greatly reduced. Rectangular tube sections are similar to other open sections in this regard.

5. When necessary, concrete can also be poured in the pipe to form a composite member.

6. Its node connection is suitable for direct welding, which does not need to pass through the gusset plate or other connecting parts, which saves labor and materials.

Disadvantages of straight seam steel pipe:

1. Residual stress caused by uneven cooling. Residual stress is the internal self-equilibrium stress without external force. Hot-rolled steel sections of various cross-sections have this kind of residual stress. Generally, the larger the section size of the steel section, the greater the residual stress. Although the residual stress is self-equilibrium, it still has some influence on the performance of the steel member under the action of external force. For example, it may have adverse effects on deformation, stability, fatigue resistance, etc.

2. After welding, the non-metallic inclusions inside the straight seam steel pipe are pressed into thin sheets, and stratification occurs. Delamination makes the 20# straight seam steel pipe tensile in the thickness direction, and there may be interlaminar tearing when the weld shrinks. The local strain induced by weld shrinkage often reaches several times the yield point strain, which is much larger than the strain caused by the load.