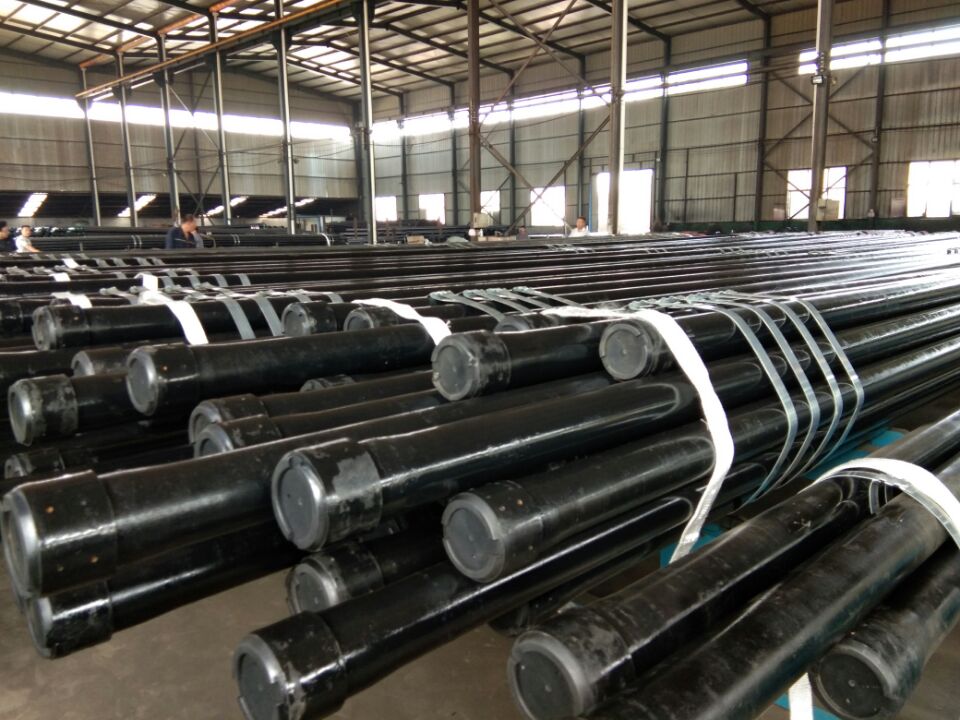

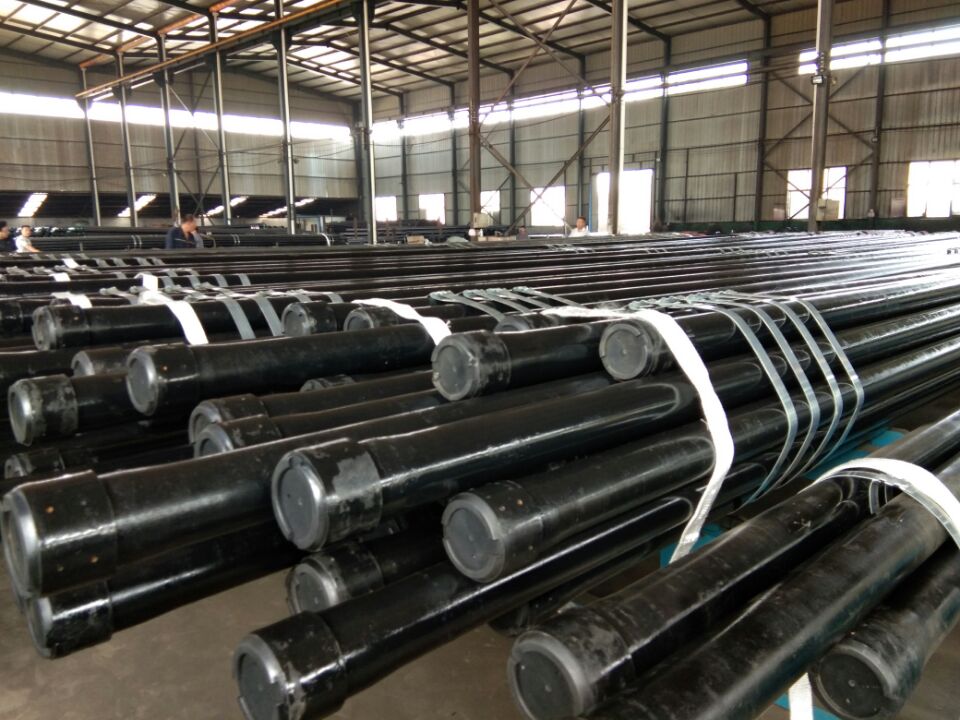

Casing pipe is a steel pipe used to support the walls of oil and gas wells to ensure the normal operation of the entire oil well after the drilling process and completion. Each well uses several layers of casing according to different drill pipe and geological conditions. Cement cementing is used after the casing is lowered into the well. Unlike oil pipes and drill pipes, it cannot be reused and is a one-time consumable material. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes.

Casing pipe hydrostatic pressure test procedure:

Each pipe shall be hydrostatically tested over its full length after upsetting (if applicable) and after final heat treatment (if applicable) and shall be free from leakage to at least the hydrostatic test pressure. The holding time of the full pressure test state should not be less than 5s. For electric welded pipes, the pipe welds should be checked for leaks under full pressure. The mill performing the threading shall hydrostatically test the pipe (or make arrangements for such a test) over the full length of the pipe unless the full length test has been previously performed at least at the pressure required by the final pipe end condition. The test should be carried out under one of the following conditions:

1. Flat-end non-upset tubes that are no longer upset or heat-treated;

2. Flat-end non-thickened tube after heat treatment;

3. Plain-end tubes that are no longer heat-treated after thickening;

Note: If this pipe has been tested for its full length under the test pressure of threaded and jointed box in the plain end state before thickening. Then, after thickening, the pressure test of the thickened part can be carried out with a test device with a pressure test wall head seal behind the heated pipe section during thickening.

4. Flat end thickening tube after heat treatment;

5. Pipe with thread and machine tight connection.

Matters needing attention in hydrostatic pressure test of oil casing

1. For pipes requiring heat treatment, the test should be carried out after the final heat treatment. For all pipes with threaded ends, the test pressure shall be at least that of the threaded and boxed ends.

2. The pup joints processed to the final plain end size and after any heat treatment shall be tested in the plain end or threaded state.

3. The testing machine should be equipped with a device to ensure that the specified test pressure and time interval requirements are met. The test pressure measuring device should be calibrated with a static load pressure testing machine or equivalent equipment within 4 months before each use.

4. Pup joints made from a single piece of tubing or casing that has been previously hydrostatically tested are not required to be hydrostatically tested if they are not subsequently heat treated.

Note 1: The surface of martensitic steel is easy to be scratched, so special measures may need to be taken to treat the thread surface and/or apply lubricating oil to minimize surface damage during the hydrostatic test (installation and removal of plugs) .

Note 2: Various types of hydrostatic testing systems are available. It is the responsibility of the plant performing the hydrostatic testing to develop a test procedure to ensure that the possibility of damage to the threads of the pipe and the pipe and connection box is minimized.

Casing pipe hydrostatic pressure test procedure:

Each pipe shall be hydrostatically tested over its full length after upsetting (if applicable) and after final heat treatment (if applicable) and shall be free from leakage to at least the hydrostatic test pressure. The holding time of the full pressure test state should not be less than 5s. For electric welded pipes, the pipe welds should be checked for leaks under full pressure. The mill performing the threading shall hydrostatically test the pipe (or make arrangements for such a test) over the full length of the pipe unless the full length test has been previously performed at least at the pressure required by the final pipe end condition. The test should be carried out under one of the following conditions:

1. Flat-end non-upset tubes that are no longer upset or heat-treated;

2. Flat-end non-thickened tube after heat treatment;

3. Plain-end tubes that are no longer heat-treated after thickening;

Note: If this pipe has been tested for its full length under the test pressure of threaded and jointed box in the plain end state before thickening. Then, after thickening, the pressure test of the thickened part can be carried out with a test device with a pressure test wall head seal behind the heated pipe section during thickening.

4. Flat end thickening tube after heat treatment;

5. Pipe with thread and machine tight connection.

Matters needing attention in hydrostatic pressure test of oil casing

1. For pipes requiring heat treatment, the test should be carried out after the final heat treatment. For all pipes with threaded ends, the test pressure shall be at least that of the threaded and boxed ends.

2. The pup joints processed to the final plain end size and after any heat treatment shall be tested in the plain end or threaded state.

3. The testing machine should be equipped with a device to ensure that the specified test pressure and time interval requirements are met. The test pressure measuring device should be calibrated with a static load pressure testing machine or equivalent equipment within 4 months before each use.

4. Pup joints made from a single piece of tubing or casing that has been previously hydrostatically tested are not required to be hydrostatically tested if they are not subsequently heat treated.

Note 1: The surface of martensitic steel is easy to be scratched, so special measures may need to be taken to treat the thread surface and/or apply lubricating oil to minimize surface damage during the hydrostatic test (installation and removal of plugs) .

Note 2: Various types of hydrostatic testing systems are available. It is the responsibility of the plant performing the hydrostatic testing to develop a test procedure to ensure that the possibility of damage to the threads of the pipe and the pipe and connection box is minimized.