Rectangular tubes (such as a500 square tube and a500 rectangular tube) are a name for square tubes and rectangular tubes, that is, steel tubes with equal and unequal side lengths. It is made of strip steel after process treatment. Generally, the strip steel is unpacked, flattened, crimped, welded to form a round tube, and then rolled into a square tube from the round tube and then cut to the required length.

Choose the right square tube according to your needs

1. Material selection: The common materials of rectangular tubes are steel, aluminum and stainless steel. According to the specific application environment and requirements, select the corresponding material. Steel has the characteristics of high strength, wear resistance and corrosion resistance, and is suitable for places with high load-bearing requirements. Aluminum has the characteristics of lightness, easy processing and oxidation resistance, and is suitable for places with lighter requirements. Stainless steel has the characteristics of high temperature resistance and corrosion resistance, and is suitable for special environments.

2. Size selection: Choose the right size according to your specific needs. The size of the square rectangular tube is usually determined by two parameters of width and height. Common specifications are 25x25mm, 50x50mm, 100x100mm, etc. The space constraints of the place of use and the load-bearing requirements of specific applications need to be considered.

3. Thickness selection: The thickness of the square tube determines its load-bearing capacity and bending resistance. The larger the thickness, the higher the strength, and it is suitable for places with higher load-bearing requirements. Common thicknesses are 1.5mm, 2.0mm, 3.0mm, etc., which can be selected according to specific needs.

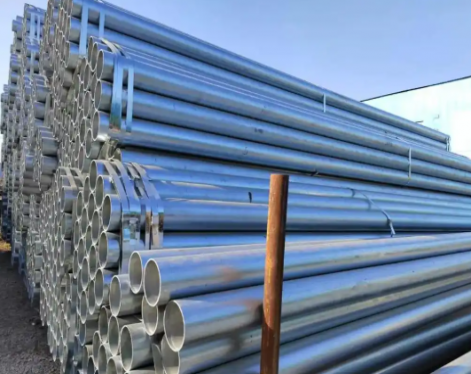

4. Surface treatment: Rectangular pipes are usually surface treated to increase their ability to resist rust and corrosion. Common surface treatment methods include hot-dip galvanizing and spraying. According to the specific environment and requirements, choose the appropriate surface treatment method.

5. Quality certification: When purchasing, make sure that the square tube meets the relevant standards and quality certification requirements to ensure its reliable quality.

6. Price comparison: While considering the above factors, it is also necessary to compare the prices of square and rectangular tubes from different suppliers or brands, and consider the final purchase in combination with the cost performance.

How to identify inferior square and rectangular tubes

1. Look at its folded condition. Inferior square rectangular tubes are prone to folds, and we can see some folded lines on the outside of the tubes, which fully demonstrate that the product is easy to fold. The reason why low-quality products have many fold lines is generally because the manufacturer pursues high output and high efficiency when producing products, which leads to a large amount of processed products, and folding marks will inevitably appear due to the large amount during rolling. If these square tubes are purchased, these broken lines are prone to breakage. Therefore special attention must be paid.

2. It depends on the surface appearance of the product. The surface of inferior products will have unevenness, and it will feel numb to the touch, while high-quality steel will not have such a bad feel. The reason for the tactility and appearance of the product is that the manufacturer's rolling exceeds the standard, which is often caused by the irresponsibility of the manufacturer who one-sidedly pursues production profits. In addition, the appearance of poor-quality pipes is prone to some cracks, usually because the production process is not strictly controlled, and there are problems in the procedure.

3. When purchasing, you can also judge its quality by its gloss. Inferior products lack the luster of metal and tend to appear reddish. There are two main reasons for this. First, the temperature set by the industrial workshop is not up to the standard during rolling. Secondly, the steel temperature is not measured accurately, often by visual inspection, so the rigidity of the steel naturally cannot meet the standard.

Choose the right square tube according to your needs

1. Material selection: The common materials of rectangular tubes are steel, aluminum and stainless steel. According to the specific application environment and requirements, select the corresponding material. Steel has the characteristics of high strength, wear resistance and corrosion resistance, and is suitable for places with high load-bearing requirements. Aluminum has the characteristics of lightness, easy processing and oxidation resistance, and is suitable for places with lighter requirements. Stainless steel has the characteristics of high temperature resistance and corrosion resistance, and is suitable for special environments.

2. Size selection: Choose the right size according to your specific needs. The size of the square rectangular tube is usually determined by two parameters of width and height. Common specifications are 25x25mm, 50x50mm, 100x100mm, etc. The space constraints of the place of use and the load-bearing requirements of specific applications need to be considered.

3. Thickness selection: The thickness of the square tube determines its load-bearing capacity and bending resistance. The larger the thickness, the higher the strength, and it is suitable for places with higher load-bearing requirements. Common thicknesses are 1.5mm, 2.0mm, 3.0mm, etc., which can be selected according to specific needs.

4. Surface treatment: Rectangular pipes are usually surface treated to increase their ability to resist rust and corrosion. Common surface treatment methods include hot-dip galvanizing and spraying. According to the specific environment and requirements, choose the appropriate surface treatment method.

5. Quality certification: When purchasing, make sure that the square tube meets the relevant standards and quality certification requirements to ensure its reliable quality.

6. Price comparison: While considering the above factors, it is also necessary to compare the prices of square and rectangular tubes from different suppliers or brands, and consider the final purchase in combination with the cost performance.

How to identify inferior square and rectangular tubes

1. Look at its folded condition. Inferior square rectangular tubes are prone to folds, and we can see some folded lines on the outside of the tubes, which fully demonstrate that the product is easy to fold. The reason why low-quality products have many fold lines is generally because the manufacturer pursues high output and high efficiency when producing products, which leads to a large amount of processed products, and folding marks will inevitably appear due to the large amount during rolling. If these square tubes are purchased, these broken lines are prone to breakage. Therefore special attention must be paid.

2. It depends on the surface appearance of the product. The surface of inferior products will have unevenness, and it will feel numb to the touch, while high-quality steel will not have such a bad feel. The reason for the tactility and appearance of the product is that the manufacturer's rolling exceeds the standard, which is often caused by the irresponsibility of the manufacturer who one-sidedly pursues production profits. In addition, the appearance of poor-quality pipes is prone to some cracks, usually because the production process is not strictly controlled, and there are problems in the procedure.

3. When purchasing, you can also judge its quality by its gloss. Inferior products lack the luster of metal and tend to appear reddish. There are two main reasons for this. First, the temperature set by the industrial workshop is not up to the standard during rolling. Secondly, the steel temperature is not measured accurately, often by visual inspection, so the rigidity of the steel naturally cannot meet the standard.