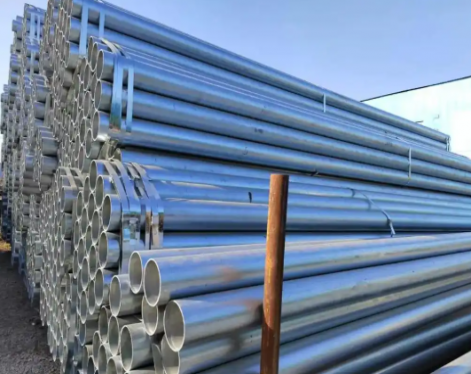

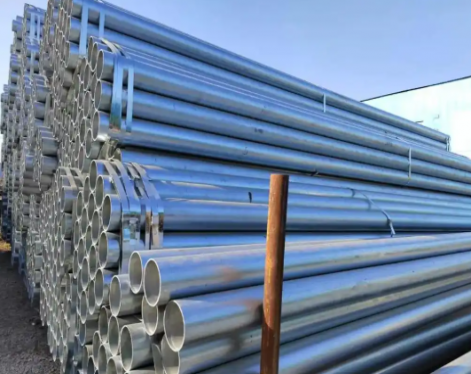

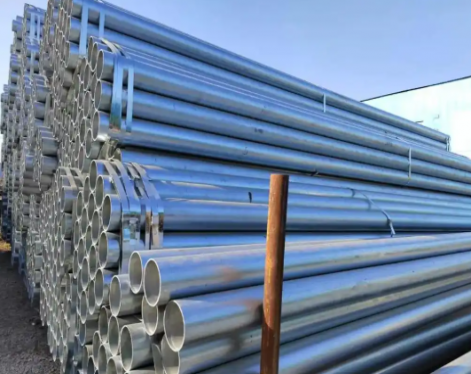

Hot-dip galvanized steel pipe is a type of steel pipe whose surface has been treated with hot-dip galvanizing. Although most hot-dip galvanized steel pipes commonly found on the market are welded pipes (such as ERW), seamless steel pipes can also be produced and supplied after hot-dip galvanizing – that is, hot-dip galvanizing is applied to regular seamless pipes to enhance their corrosion resistance.

This type of steel pipe features strong corrosion resistance (with a lifespan of 20-30 years), high strength (suitable for high-pressure and heavy-load environments), and an aesthetically pleasing appearance (silver-gray zinc coating). Common specifications include outer diameters from Φ10mm to Φ600mm and wall thicknesses from 1.0mm to 50mm. It is widely used in petroleum and natural gas transportation, building structures, machinery manufacturing, power generation, and chemical industries.

1. Steel pipe preparation: High-quality carbon structural steel is selected as the raw material. The steel pipes undergo processes such as cutting, straightening, and cleaning to ensure a smooth and flawless surface, free from oil and impurities.

2. Pickling: The steel pipes are immersed in an acidic solution for pickling to remove the oxide layer and rust from the surface, ensuring the adhesion and quality of the coating.

3. Cleaning: The pickled steel pipes are cleaned to remove residual pickling solution and prevent adverse effects on the coating.

4. Hot-dip galvanizing: The cleaned steel pipes are immersed in molten zinc. Through a chemical reaction, a zinc-iron alloy coating is formed on the surface of the steel pipe, providing excellent corrosion resistance.

5. Inspection and packaging: The hot-dip galvanized seamless steel pipes undergo strict quality inspection and are then packaged to ensure the product is intact and undamaged.

ASTM A106 / ASTM A53 Type S

API 5L

EN 10216

GB/T 8163, GB/T 3087

Galvanizing thickness typically complies with standards like ASTM A123 or EN ISO 1461, depending on project requirements.

For projects exposed to harsh environments or requiring high pressure resistance, hot-dip galvanized seamless steel pipes remain one of the most reliable options in the global steel pipe market.

This type of steel pipe features strong corrosion resistance (with a lifespan of 20-30 years), high strength (suitable for high-pressure and heavy-load environments), and an aesthetically pleasing appearance (silver-gray zinc coating). Common specifications include outer diameters from Φ10mm to Φ600mm and wall thicknesses from 1.0mm to 50mm. It is widely used in petroleum and natural gas transportation, building structures, machinery manufacturing, power generation, and chemical industries.

How are hot-dip galvanized seamless steel pipes manufactured?

The manufacturing process of hot-dip galvanized seamless steel pipes includes the following main steps:1. Steel pipe preparation: High-quality carbon structural steel is selected as the raw material. The steel pipes undergo processes such as cutting, straightening, and cleaning to ensure a smooth and flawless surface, free from oil and impurities.

2. Pickling: The steel pipes are immersed in an acidic solution for pickling to remove the oxide layer and rust from the surface, ensuring the adhesion and quality of the coating.

3. Cleaning: The pickled steel pipes are cleaned to remove residual pickling solution and prevent adverse effects on the coating.

4. Hot-dip galvanizing: The cleaned steel pipes are immersed in molten zinc. Through a chemical reaction, a zinc-iron alloy coating is formed on the surface of the steel pipe, providing excellent corrosion resistance.

5. Inspection and packaging: The hot-dip galvanized seamless steel pipes undergo strict quality inspection and are then packaged to ensure the product is intact and undamaged.

Applicable Standards and Specifications for Hot-Dip Galvanized SMLS Pipes

Hot-dip galvanized seamless steel pipes are usually manufactured in accordance with international standards such as:ASTM A106 / ASTM A53 Type S

API 5L

EN 10216

GB/T 8163, GB/T 3087

Galvanizing thickness typically complies with standards like ASTM A123 or EN ISO 1461, depending on project requirements.

Conclusion

Hot-dip galvanized seamless steel pipe is a high-performance piping solution that combines seamless pipe strength with long-lasting corrosion protection. Although it has a higher initial cost than welded alternatives, its durability, reliability, and reduced maintenance needs make it a cost-effective choice over the long term.For projects exposed to harsh environments or requiring high pressure resistance, hot-dip galvanized seamless steel pipes remain one of the most reliable options in the global steel pipe market.