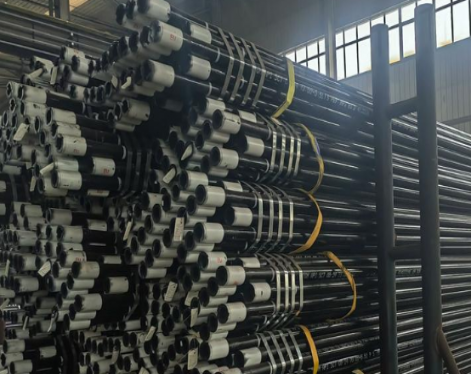

Packaging of spiral steel pipe (SSAW pipe)

1. Spiral steel pipe packaging should be able to avoid loosening and damage during normal loading, unloading, transportation and storage.

2. If the buyer has special requirements for the packaging materials and methods of spiral steel pipes, it should be specified in the contract. If not specified, the packaging material and packaging method are optional by the supplier.

3. Packaging materials should comply with relevant regulations. If there is no requirement for packaging materials, they should meet the intended purpose and avoid waste and environmental pollution.

4. If the customer requires that the spiral steel pipes not have damage such as bumps on the outside, it can be considered to use a protective device between the spiral steel pipes. The protective device can use rubber, straw rope, fiber cloth, plastic, pipe cap and so on.

5. Thin-walled spiral steel pipes can be protected by internal support or external frame protection due to their thick walls and thin walls. The material of the bracket and the outer frame adopts the same steel material as the spiral steel pipe.

6. The state stipulates that the spiral steel pipes shall be packed in bulk. If the customer requires bundling, it can be considered as appropriate, but the caliber must be between 159MM and 500MM. The bundled materials are packed and fastened with steel belts, and each strand should be twisted into at least two strands, and should be appropriately increased according to the outer diameter and weight of the spiral steel pipe to prevent loosening.

7. The fixed-length spiral steel pipe may not be bundled.

8. If there are threaded buckles at both ends of the spiral steel pipe, it should be protected by a thread protector. Apply lubricating oil or anti-rust agent to the threaded fasteners. Both ends of the spiral steel pipe are breached, and nozzle protectors can be added at both ends according to requirements.

9. If the spiral steel pipe is put into the container, the container should be covered with soft moisture-proof devices such as textile cloth and straw mat. In order to scatter the spiral steel pipe in the container, it can be bundled or welded with protective brackets outside the spiral steel pipe, etc.

Installation and use of spiral steel pipe

After the spiral steel pipe is transported to the destination, there are strict technical requirements for the installation and use of the spiral steel pipe, which must be carried out according to the actual situation and the operating procedures to ensure safety and quality. In the general use process, the spiral steel pipe needs to pay attention to the following points

1. Construction preparation before use of spiral steel pipe

Pipeline trenches should be dug well, and pipe wells should be built well. All kinds of spiral steel pipes and tools needed, including welding machines, cutting machines, electric hammers, polishing machines, etc., must be fully prepared. Only after a series of preparations can the installation begin.

2. Installation of spiral steel pipe

According to the drawing design, prefabricate the pipe support according to the site conditions, then punch out according to the design and site, then polish the groove with a polishing machine, and then weld it.

3. Use quality requirements

(1) The vertical installation deviation of the riser should be less than 3 mm per meter, and the horizontal installation deviation should be less than 1 mm.

(2) The branch pipe should not be welded at the weld, and welding should be avoided at the bend.

(3) The welding must be straight, the weld seam is complete, and the surface of the weld seam has no burn-through and cracks.

Tips: SSAW pipe refers to the welded steel tube with spiral seam welded by submerged arc welding process. Generally used in: welding into pipelines for fluid transportation, metal structures, pile foundations, etc. The feature is that it can produce welded pipes with larger diameters with narrower blanks, and it can also produce welded pipes with different diameters with the same width blanks. The production cost is low, the process is simple, and it is easy to produce large-diameter pipes.

1. Spiral steel pipe packaging should be able to avoid loosening and damage during normal loading, unloading, transportation and storage.

2. If the buyer has special requirements for the packaging materials and methods of spiral steel pipes, it should be specified in the contract. If not specified, the packaging material and packaging method are optional by the supplier.

3. Packaging materials should comply with relevant regulations. If there is no requirement for packaging materials, they should meet the intended purpose and avoid waste and environmental pollution.

4. If the customer requires that the spiral steel pipes not have damage such as bumps on the outside, it can be considered to use a protective device between the spiral steel pipes. The protective device can use rubber, straw rope, fiber cloth, plastic, pipe cap and so on.

5. Thin-walled spiral steel pipes can be protected by internal support or external frame protection due to their thick walls and thin walls. The material of the bracket and the outer frame adopts the same steel material as the spiral steel pipe.

6. The state stipulates that the spiral steel pipes shall be packed in bulk. If the customer requires bundling, it can be considered as appropriate, but the caliber must be between 159MM and 500MM. The bundled materials are packed and fastened with steel belts, and each strand should be twisted into at least two strands, and should be appropriately increased according to the outer diameter and weight of the spiral steel pipe to prevent loosening.

7. The fixed-length spiral steel pipe may not be bundled.

8. If there are threaded buckles at both ends of the spiral steel pipe, it should be protected by a thread protector. Apply lubricating oil or anti-rust agent to the threaded fasteners. Both ends of the spiral steel pipe are breached, and nozzle protectors can be added at both ends according to requirements.

9. If the spiral steel pipe is put into the container, the container should be covered with soft moisture-proof devices such as textile cloth and straw mat. In order to scatter the spiral steel pipe in the container, it can be bundled or welded with protective brackets outside the spiral steel pipe, etc.

Installation and use of spiral steel pipe

After the spiral steel pipe is transported to the destination, there are strict technical requirements for the installation and use of the spiral steel pipe, which must be carried out according to the actual situation and the operating procedures to ensure safety and quality. In the general use process, the spiral steel pipe needs to pay attention to the following points

1. Construction preparation before use of spiral steel pipe

Pipeline trenches should be dug well, and pipe wells should be built well. All kinds of spiral steel pipes and tools needed, including welding machines, cutting machines, electric hammers, polishing machines, etc., must be fully prepared. Only after a series of preparations can the installation begin.

2. Installation of spiral steel pipe

According to the drawing design, prefabricate the pipe support according to the site conditions, then punch out according to the design and site, then polish the groove with a polishing machine, and then weld it.

3. Use quality requirements

(1) The vertical installation deviation of the riser should be less than 3 mm per meter, and the horizontal installation deviation should be less than 1 mm.

(2) The branch pipe should not be welded at the weld, and welding should be avoided at the bend.

(3) The welding must be straight, the weld seam is complete, and the surface of the weld seam has no burn-through and cracks.

Tips: SSAW pipe refers to the welded steel tube with spiral seam welded by submerged arc welding process. Generally used in: welding into pipelines for fluid transportation, metal structures, pile foundations, etc. The feature is that it can produce welded pipes with larger diameters with narrower blanks, and it can also produce welded pipes with different diameters with the same width blanks. The production cost is low, the process is simple, and it is easy to produce large-diameter pipes.

Previous:Chemical cleaning of steel pipes

Next:Types of fire hoses