The seamless pipe is transported by a special trailer with a length of 18m. The trailer is covered with 100mm×200mm wooden squares, and the wooden squares are covered with rubber cushions or straw bags. The thickness is not less than 10mm and the width is not less than 300mm.A rubber band or fine soil bag is laid between the two layers of the seamless pipe. During transportation, the pipes must be tied firmly to prevent the phenomenon of pipe rolling and pipe shooting, and special slings are used for bundling.

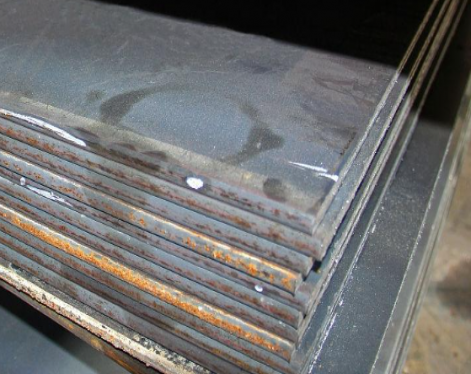

During the whole process of hoisting, transportation and stacking, the nozzle should be kept intact and not damaged. Use a cross to fix and protect the nozzle to prevent deformation. The stacking site should be flat and solid, and two sleepers with a distance of 4-8m should be placed under the stacking (section 300×300mm).Sandbags or fine soil bags should be placed between sleepers and anti-corrosion pipes. There should be fixed wedge blocks on the sleepers at the edge of the pipe stack to prevent the pipes from slipping.

Before unloading the seamless pipe, the unloading pipe pier should be laid at the pre-unloading position.The distance between the lower surface of the seamless pipe and the ground is 0.5~0.7m, and a straw mat is placed on the fine soil pillow to protect the anti-corrosion layer.Three seamless pipes are unloaded from the bottom of each group of pipe piers, and the distance between each seamless pipe is 0.2m, which is convenient for the wearing and hanging of slings. The distance between each group of pipe piers should be 6-8 meters, and the distance between two piles of pipe piers should be about 8 meters. It is convenient for the crane to stand in the middle to unload pipes on both sides. Both sides of the pipe pier shall be covered with woven bags or compacted fine earth mounds;If multi-layer stacking is required, no more than two layers are allowed, and the upper pipe must fall between the lower two pipes to prevent the pipe from rolling (climbing is strictly prohibited by spraying on the surface of the pipe). In general areas (except the stacking yard), the on-site unloading must be unloaded to the first floor, and it is strictly forbidden to have two floors.

When unloading, check the integrity of the seamless pipe in time, record the damage of the nozzle and the anti-corrosion layer in the seamless pipe receiving book, and the manufacturer will arrange personnel to repair it in time. For unqualified quality, such as the seamless pipe with serious damage and serious pipe deformation, it shall not be accepted.

Note: When loading and unloading, special pipe lifting tools such as iron poles, steel wire ropes, 5T lifting belts, etc. should be used. Four slings are wound on the seamless pipe at equal distances, and the iron pole is connected with the sling through steel wire ropes and hooks to lift the seamless pipe. It is absolutely not allowed to use wire rope directly to prevent damage to the nozzle. When loading and unloading, pay attention that the pipes cannot collide or scratch each other.

According to the completion of the excavation base of the pipe trench, the pipes are unloaded one by one at the exact position of the construction site along the pipeline, and the pipes are padded with soil-filled woven bags. Pay attention to control the arrangement length of the seamless pipe and the length of the pipe trench to avoid missing pipes and multiple pipes, which will lead to pipe supplementation and pipe transfer. Pipeline transportation and pipe layout are completed in one step to avoid secondary reverse transportation. Pipes are installed in areas where roads, rivers, etc. pass through.

Stack the site, and the pipes are padded with soil-filled woven bags. In the uneven area along the pipe trench, the site should be leveled to facilitate on-site pipe layout and welding.

During the whole process of hoisting, transportation and stacking, the nozzle should be kept intact and not damaged. Use a cross to fix and protect the nozzle to prevent deformation. The stacking site should be flat and solid, and two sleepers with a distance of 4-8m should be placed under the stacking (section 300×300mm).Sandbags or fine soil bags should be placed between sleepers and anti-corrosion pipes. There should be fixed wedge blocks on the sleepers at the edge of the pipe stack to prevent the pipes from slipping.

Before unloading the seamless pipe, the unloading pipe pier should be laid at the pre-unloading position.The distance between the lower surface of the seamless pipe and the ground is 0.5~0.7m, and a straw mat is placed on the fine soil pillow to protect the anti-corrosion layer.Three seamless pipes are unloaded from the bottom of each group of pipe piers, and the distance between each seamless pipe is 0.2m, which is convenient for the wearing and hanging of slings. The distance between each group of pipe piers should be 6-8 meters, and the distance between two piles of pipe piers should be about 8 meters. It is convenient for the crane to stand in the middle to unload pipes on both sides. Both sides of the pipe pier shall be covered with woven bags or compacted fine earth mounds;If multi-layer stacking is required, no more than two layers are allowed, and the upper pipe must fall between the lower two pipes to prevent the pipe from rolling (climbing is strictly prohibited by spraying on the surface of the pipe). In general areas (except the stacking yard), the on-site unloading must be unloaded to the first floor, and it is strictly forbidden to have two floors.

When unloading, check the integrity of the seamless pipe in time, record the damage of the nozzle and the anti-corrosion layer in the seamless pipe receiving book, and the manufacturer will arrange personnel to repair it in time. For unqualified quality, such as the seamless pipe with serious damage and serious pipe deformation, it shall not be accepted.

Note: When loading and unloading, special pipe lifting tools such as iron poles, steel wire ropes, 5T lifting belts, etc. should be used. Four slings are wound on the seamless pipe at equal distances, and the iron pole is connected with the sling through steel wire ropes and hooks to lift the seamless pipe. It is absolutely not allowed to use wire rope directly to prevent damage to the nozzle. When loading and unloading, pay attention that the pipes cannot collide or scratch each other.

According to the completion of the excavation base of the pipe trench, the pipes are unloaded one by one at the exact position of the construction site along the pipeline, and the pipes are padded with soil-filled woven bags. Pay attention to control the arrangement length of the seamless pipe and the length of the pipe trench to avoid missing pipes and multiple pipes, which will lead to pipe supplementation and pipe transfer. Pipeline transportation and pipe layout are completed in one step to avoid secondary reverse transportation. Pipes are installed in areas where roads, rivers, etc. pass through.

Stack the site, and the pipes are padded with soil-filled woven bags. In the uneven area along the pipe trench, the site should be leveled to facilitate on-site pipe layout and welding.