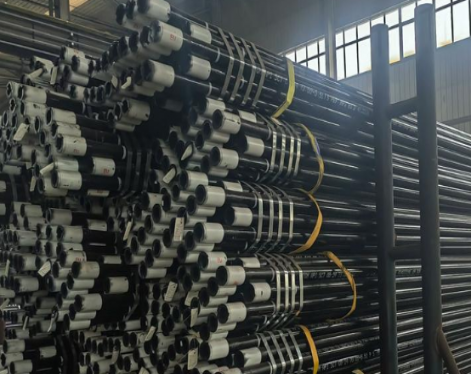

The pre-finishing welding process technology is the most advanced tube-making process technology in the spiral submerged arc welded pipe (SSAW pipe). Its advantage is to effectively solve the problem of mutual interference between forming and welding, give full play to the respective advantages of forming and welding, and realize the organic combination of high-speed forming and low-speed welding. The output and quality of the production line are greatly improved, and the production cost is effectively reduced.

The pre-finishing welding process is to separate the spiral forming and welding, also known as the two-step method.

1.the steel strip is formed into a tube at high speed, and carbon dioxide gas shielded welding is used for pre-welding.

2.The pre-welded steel pipes are finally welded on the separate finishing welding equipment in the finishing area. The internal and external welding can be multi-wire submerged arc welding according to different situations.

Spiral steel pipe two-step welding process

Steel strip flattening→steel strip edge milling→steel pipe forming→mixed gas shielded high-speed pre-welding internal welding→pipe cutting→pre-welding finishing (pre-weld seam repair, steel pipe internal cleaning, arc-extinguishing plate welding)→Precision welding internal and external submerged arc automatic welding

Compared with one-step welding spiral steel pipe, the two-step welding spiral steel pipe can reduce the influence of dynamic stress on the quality of internal welding during the steel pipe forming process. At the same time, the high-speed pre-welded pipe billet of the welded pipe host can be matched with an appropriate number of fine welding machines to greatly increase the production capacity of the steel pipe. Therefore, more and more welded pipe companies use the two-step method to weld spiral steel pipes.

Tips: The fine welding unit is composed of lead and arc extinguishing plate welding devices, pipe transport trolley, conveying roller table, fine welding bench and so on.

The fine welding bench is composed of conveying roller table, longitudinal transmission track, transverse transport vehicle, orthogonal roller table and driving frame, internal welding system, external welding system, operating system and so on.

The pre-finishing welding process is to separate the spiral forming and welding, also known as the two-step method.

1.the steel strip is formed into a tube at high speed, and carbon dioxide gas shielded welding is used for pre-welding.

2.The pre-welded steel pipes are finally welded on the separate finishing welding equipment in the finishing area. The internal and external welding can be multi-wire submerged arc welding according to different situations.

Spiral steel pipe two-step welding process

Steel strip flattening→steel strip edge milling→steel pipe forming→mixed gas shielded high-speed pre-welding internal welding→pipe cutting→pre-welding finishing (pre-weld seam repair, steel pipe internal cleaning, arc-extinguishing plate welding)→Precision welding internal and external submerged arc automatic welding

Compared with one-step welding spiral steel pipe, the two-step welding spiral steel pipe can reduce the influence of dynamic stress on the quality of internal welding during the steel pipe forming process. At the same time, the high-speed pre-welded pipe billet of the welded pipe host can be matched with an appropriate number of fine welding machines to greatly increase the production capacity of the steel pipe. Therefore, more and more welded pipe companies use the two-step method to weld spiral steel pipes.

Tips: The fine welding unit is composed of lead and arc extinguishing plate welding devices, pipe transport trolley, conveying roller table, fine welding bench and so on.

The fine welding bench is composed of conveying roller table, longitudinal transmission track, transverse transport vehicle, orthogonal roller table and driving frame, internal welding system, external welding system, operating system and so on.