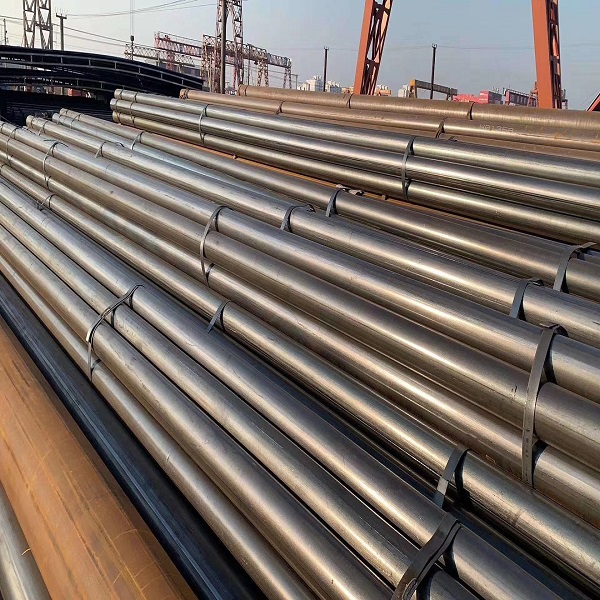

Seamless pipe is a metal pipe with a seamless structure, which is widely used in petroleum, natural gas, chemical industry, electric power, aerospace and other fields. Compared with welded pipes, seamless steel pipes have higher strength and pressure resistance, so they perform well in high-pressure and high-temperature environments.

Fluid seamless pipe is a pipe used to transport fluid. Its inner wall is smooth and seamless, which can ensure smooth flow of fluid. The specifications of fluid seamless pipes vary according to different needs and application areas. Some common fluid seamless pipe specifications are introduced below.

1. Outside diameter and wall thickness. The outer diameter and wall thickness of fluid seamless pipes are the basic specifications. The larger the outer diameter, the stronger the carrying capacity of the pipe, and it is suitable for transporting large flows of fluid. The larger the wall thickness, the stronger the pressure resistance of the pipeline, making it suitable for transporting high-pressure fluids. Common outer diameter and wall thickness specifications include 6mm×1mm, 8mm×1mm, 10mm×1mm, 12mm×1mm, etc.

2. Material fluid. The material of the seamless pipe is also an important part of its specifications. Common materials include stainless steel, copper, aluminum, plastic, etc. Different materials have different characteristics and are suitable for different working environments and fluid media. For example, stainless steel seamless pipes are corrosion-resistant and high-temperature resistant and are suitable for chemical industry, petroleum and other fields; copper seamless pipes have good thermal conductivity and are suitable for refrigeration, air conditioning and other fields.

3. Length fluid. The length of seamless pipe is also part of its specifications. Common lengths include fixed length and random length. Fixed lengths are generally 6 meters, 3 meters, etc., which are suitable for occasions where length is required; random lengths are generally 12 meters, 18 meters, etc., which are suitable for occasions where cutting is required according to actual conditions.

4. Surface treatment. The surface treatment of fluid seamless pipes is also part of its specifications. Common surface treatment methods include brightening, sandblasting, pickling, etc. Brightening treatment can increase the aesthetics of the pipeline and is suitable for occasions with higher requirements; sandblasting treatment can increase the roughness of the pipeline and improve the anti-skid performance of the pipeline, and is suitable for occasions where anti-skid is required; pickling treatment can remove oxidation on the surface of the pipeline layer to improve the corrosion resistance of the pipeline and is suitable for occasions requiring high corrosion resistance.

5. Connection method. The way fluid seamless pipes are connected is also part of their specifications. Common connection methods include welding, threaded connection, flange connection, etc. The welded connection can provide strong connection strength and is suitable for high-pressure and high-temperature situations; the threaded connection can provide better sealing performance and is suitable for low-pressure and low-temperature situations; the flange connection can provide a larger connection range and is suitable for needs Frequent disassembly situations.

The specifications of fluid seamless pipes include outer diameter and wall thickness, material, length, surface treatment and connection method, etc. When selecting fluid seamless pipes, appropriate specifications need to be determined based on actual needs and application environment to ensure safe and reliable operation of the pipeline.

Fluid seamless pipe is a pipe used to transport fluid. Its inner wall is smooth and seamless, which can ensure smooth flow of fluid. The specifications of fluid seamless pipes vary according to different needs and application areas. Some common fluid seamless pipe specifications are introduced below.

1. Outside diameter and wall thickness. The outer diameter and wall thickness of fluid seamless pipes are the basic specifications. The larger the outer diameter, the stronger the carrying capacity of the pipe, and it is suitable for transporting large flows of fluid. The larger the wall thickness, the stronger the pressure resistance of the pipeline, making it suitable for transporting high-pressure fluids. Common outer diameter and wall thickness specifications include 6mm×1mm, 8mm×1mm, 10mm×1mm, 12mm×1mm, etc.

2. Material fluid. The material of the seamless pipe is also an important part of its specifications. Common materials include stainless steel, copper, aluminum, plastic, etc. Different materials have different characteristics and are suitable for different working environments and fluid media. For example, stainless steel seamless pipes are corrosion-resistant and high-temperature resistant and are suitable for chemical industry, petroleum and other fields; copper seamless pipes have good thermal conductivity and are suitable for refrigeration, air conditioning and other fields.

3. Length fluid. The length of seamless pipe is also part of its specifications. Common lengths include fixed length and random length. Fixed lengths are generally 6 meters, 3 meters, etc., which are suitable for occasions where length is required; random lengths are generally 12 meters, 18 meters, etc., which are suitable for occasions where cutting is required according to actual conditions.

4. Surface treatment. The surface treatment of fluid seamless pipes is also part of its specifications. Common surface treatment methods include brightening, sandblasting, pickling, etc. Brightening treatment can increase the aesthetics of the pipeline and is suitable for occasions with higher requirements; sandblasting treatment can increase the roughness of the pipeline and improve the anti-skid performance of the pipeline, and is suitable for occasions where anti-skid is required; pickling treatment can remove oxidation on the surface of the pipeline layer to improve the corrosion resistance of the pipeline and is suitable for occasions requiring high corrosion resistance.

5. Connection method. The way fluid seamless pipes are connected is also part of their specifications. Common connection methods include welding, threaded connection, flange connection, etc. The welded connection can provide strong connection strength and is suitable for high-pressure and high-temperature situations; the threaded connection can provide better sealing performance and is suitable for low-pressure and low-temperature situations; the flange connection can provide a larger connection range and is suitable for needs Frequent disassembly situations.

The specifications of fluid seamless pipes include outer diameter and wall thickness, material, length, surface treatment and connection method, etc. When selecting fluid seamless pipes, appropriate specifications need to be determined based on actual needs and application environment to ensure safe and reliable operation of the pipeline.