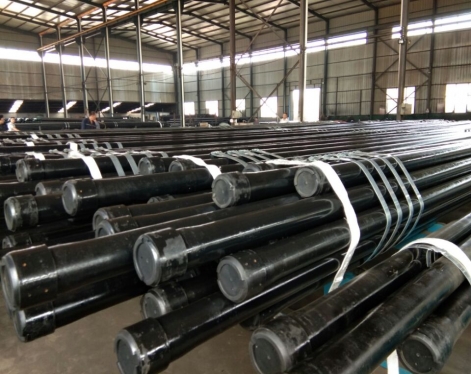

Oil casing is a steel pipe used to support the walls of oil and gas wells to ensure the normal operation of the entire oil well after the drilling process and completion. Each well uses several layers of casing according to different drilling depths and geological conditions.

Read more

Straight seam steel pipe is a welded steel pipe in which the weld seam is parallel to the longitudinal direction of the steel pipe. According to the production process, it can be divided into ERW steel pipe and LSAW steel pipe. The production process of straight seam welded pipe is simple, the production efficiency is high, the cost is low, and the development is rapid.

Read more

Continuous seamless oil pipe is a new type of oil steel pipe with a single length of several thousand meters that can be bent repeatedly and achieve multiple plastic deformations. Continuous seamless tubing and its operating equipment are called "universal working machines".

Read more

Large-diameter steel pipes are steel pipes with an outer diameter of 1000MM or more. Large-diameter steel pipes are mainly completed by tension reduction and continuous rolling of hollow base metals without mandrels. On the premise of determining the welded steel pipe, the whole welded steel pipe is heated to a high temperature above 950°C, and then rolled into seamless steel pipes of various specifications through a tension reducing machine.

Read more

Welded pipes can be divided into carbon steel welded pipes and stainless steel welded pipes in terms of material. Carbon steel welded pipe can also be called carbon welded steel pipe, and carbon steel can also be called magnet alloy steel.

Read more

Galvanized degaussing steel pipe is used as a material for pre-embedded threading in subways, high-speed rail stations, civil air defense construction, and high-voltage substations. It has a wide range of applications. Degaussing steel pipes can effectively prevent signal loss caused by wires and cables passing through pipes.

Read more