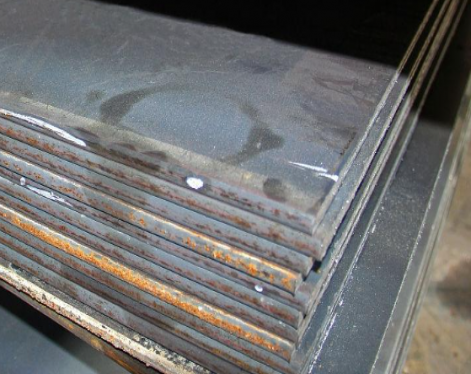

Steel sheet piling have been widely used in road construction, coastal protection, and even in rescue and disaster relief activities. However, the steel sheet piling is a kind of iron product, so the anti-corrosion work during use is very important, so how to complete the anti-corrosion work of the steel sheet piling?

steel sheet piling construction

1. The aluminum spray coating has a strong bond with the steel substrate, and the coating has a long service life. The anticorrosive steel structure has good long-term economic benefits.

2. Improve the production process. The role of excellent technology in the production and production process is very obvious. Therefore, it is necessary to pay attention to its production process when producing steel sheet pilings.

Galvanized steel sheet piling

1. Spray zinc or aluminum coating and anti-corrosion coating, which can make the steel sheet piling more difficult to rust, and will be safer, more reliable and reliable during use. Use organic protective coating or concrete envelope;

2. Use cathodic protection.

If the sheet pile wall is located in an area prone to local corrosion, one or more protective measures need to be considered in the design stage to ensure its effective life, especially in the low water level area and its vicinity. For the steel platform, rust is inevitable during the use process. Doing a good job of protection and maintenance in the application can ensure the safety and effect of the platform.

Note: Steel pile pipe are driven vertically into the ground and used as a deep foundation for large commercial and industrial buildings.

steel sheet piling construction

1. The aluminum spray coating has a strong bond with the steel substrate, and the coating has a long service life. The anticorrosive steel structure has good long-term economic benefits.

2. Improve the production process. The role of excellent technology in the production and production process is very obvious. Therefore, it is necessary to pay attention to its production process when producing steel sheet pilings.

Galvanized steel sheet piling

1. Spray zinc or aluminum coating and anti-corrosion coating, which can make the steel sheet piling more difficult to rust, and will be safer, more reliable and reliable during use. Use organic protective coating or concrete envelope;

2. Use cathodic protection.

If the sheet pile wall is located in an area prone to local corrosion, one or more protective measures need to be considered in the design stage to ensure its effective life, especially in the low water level area and its vicinity. For the steel platform, rust is inevitable during the use process. Doing a good job of protection and maintenance in the application can ensure the safety and effect of the platform.

Note: Steel pile pipe are driven vertically into the ground and used as a deep foundation for large commercial and industrial buildings.