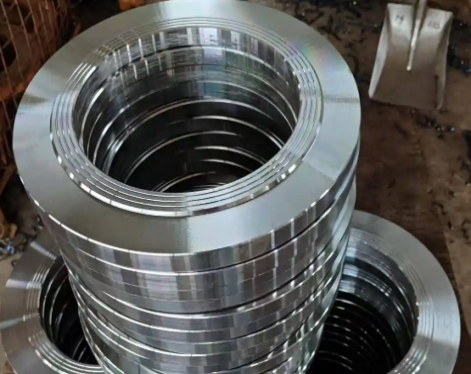

Pressure vessel flanges are common parts of pressure vessels. They are widely used in petrochemical, electric power, atomic energy, light industry and other industrial fields, and they are the basic components for connecting various pressure vessel components.

For the container, the flange is a pipe fitting, and its function is to combine different pressure components together while ensuring that there is no leakage at the connection part.

The medium inside the pressure vessel has the characteristics of high temperature and high pressure, as well as flammable and explosive characteristics or toxicity. The main failure mode of the flange connection is the failure of the rigidity of the joint, and the external manifestation is leakage. Once a leak occurs, a serious secondary disaster will occur, which will threaten the safety of the pressure vessel body and surrounding equipment and personnel. Therefore, the overall sealing performance should be a priority factor in the design and selection of container flanges.

The sealing form of the pressure vessel flange: self-tightening, the pressure of the medium in the vessel is used to generate a pressing force on the sealing surface, so as to achieve the purpose of sealing, and the sealing force increases with the increase of the medium pressure. Therefore, it can maintain reliable sealing performance under higher pressure, such as combined seal, C-ring seal, B-ring seal, O-ring seal, wedge seal, octagonal gasket and oval gasket seal, flat gasket self-tightening seal , Nitrogen type sealing, etc.; forced sealing, tightly pressing the sealing surface by tightening the connecting bolts between the end cover and the cylinder flange to achieve the purpose of sealing, such as flat gasket sealing, etc.; semi-self-tightening sealing. It not only uses the connection of fasteners to generate pressure on the sealing surface, but also uses the pressure of the medium in the container to achieve the purpose of sealing, such as double cone sealing.

The working principle of pressure vessel flange

When the bolt force reaches a certain value, due to the deformation of the gasket, the flange sealing surface and the four bumps on the gasket are forced to fill up, thereby creating an initial sealing condition for preventing the leakage of the fluid medium; when applying the flange bolts When pre-tightening, the bolt force will compress the gasket through the flange ring, forcing the flange gasket to produce compression deformation.

When the equipment or pipeline is subjected to medium pressure, the bolts are stretched under tensile stress, and the flange sealing surfaces move in the direction of separation from each other. At this time, the pressing force per unit effective sealing area of the gasket is called the initial pressure of the gasket. Seal specific pressure. The compression force between the sealing surface and the gasket decreases, the diameter of the compressed gasket decreases, and the specific pressure of the pre-tightened seal decreases.

If the elasticity of the gasket is insufficient, the specific pressure of the seal drops below the specific pressure of the working seal, or there is a gap in the sealing port again, the seal will fail; if the gasket has sufficient resilience at this time, the gasket The deformation can compensate the separation value of the bolt and the sealing surface. The pre-tightened seal specific pressure only drops to no less than the working seal specific pressure, that is, the flange maintains a good sealing state.

For the container, the flange is a pipe fitting, and its function is to combine different pressure components together while ensuring that there is no leakage at the connection part.

The medium inside the pressure vessel has the characteristics of high temperature and high pressure, as well as flammable and explosive characteristics or toxicity. The main failure mode of the flange connection is the failure of the rigidity of the joint, and the external manifestation is leakage. Once a leak occurs, a serious secondary disaster will occur, which will threaten the safety of the pressure vessel body and surrounding equipment and personnel. Therefore, the overall sealing performance should be a priority factor in the design and selection of container flanges.

The sealing form of the pressure vessel flange: self-tightening, the pressure of the medium in the vessel is used to generate a pressing force on the sealing surface, so as to achieve the purpose of sealing, and the sealing force increases with the increase of the medium pressure. Therefore, it can maintain reliable sealing performance under higher pressure, such as combined seal, C-ring seal, B-ring seal, O-ring seal, wedge seal, octagonal gasket and oval gasket seal, flat gasket self-tightening seal , Nitrogen type sealing, etc.; forced sealing, tightly pressing the sealing surface by tightening the connecting bolts between the end cover and the cylinder flange to achieve the purpose of sealing, such as flat gasket sealing, etc.; semi-self-tightening sealing. It not only uses the connection of fasteners to generate pressure on the sealing surface, but also uses the pressure of the medium in the container to achieve the purpose of sealing, such as double cone sealing.

The working principle of pressure vessel flange

When the bolt force reaches a certain value, due to the deformation of the gasket, the flange sealing surface and the four bumps on the gasket are forced to fill up, thereby creating an initial sealing condition for preventing the leakage of the fluid medium; when applying the flange bolts When pre-tightening, the bolt force will compress the gasket through the flange ring, forcing the flange gasket to produce compression deformation.

When the equipment or pipeline is subjected to medium pressure, the bolts are stretched under tensile stress, and the flange sealing surfaces move in the direction of separation from each other. At this time, the pressing force per unit effective sealing area of the gasket is called the initial pressure of the gasket. Seal specific pressure. The compression force between the sealing surface and the gasket decreases, the diameter of the compressed gasket decreases, and the specific pressure of the pre-tightened seal decreases.

If the elasticity of the gasket is insufficient, the specific pressure of the seal drops below the specific pressure of the working seal, or there is a gap in the sealing port again, the seal will fail; if the gasket has sufficient resilience at this time, the gasket The deformation can compensate the separation value of the bolt and the sealing surface. The pre-tightened seal specific pressure only drops to no less than the working seal specific pressure, that is, the flange maintains a good sealing state.