1.What is the ASTM Standard for Black Steel Pipe?

ASTM black steel pipe refers to a black steel pipe that conforms to the ASTM (American Society for Testing and Materials) standards.(1)What is the ASTM Standard?

ASTM standards are issued by ASTM International. It is one of the oldest and largest non-profit standards organizations globally and one of the largest international standard-setting bodies. It is dedicated to developing and publishing standards for various materials, including voluntary consensus technical standards for products, systems, and services. ASTM standards encompass six types: standard test methods, standard specifications, standard practices, standard terminology, standard guides, and standard classifications.These standards provide fundamental assurances for global product production, product quality and trade, and product research and development. They are widely utilized in over 100 industries such as metals, coatings, plastics, textiles, petrochemicals, construction, aviation, energy, environment, consumer goods, and medical devices. In the aerospace and defense industry, ASTM standards are also crucial reference standards, covering metals, plastics, coatings, rubber, fire-resistant textiles, electronic insulation, instrumentation, fuels, lubricants, and other areas.

(2)What is Black Steel Pipe?

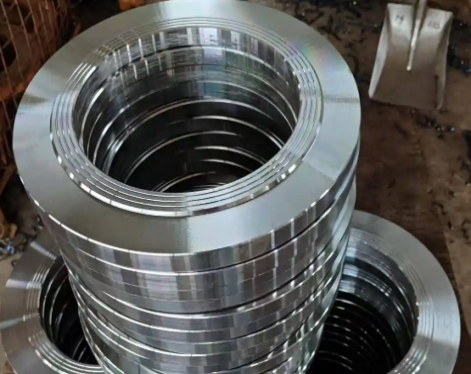

Black steel pipes are untreated carbon steel pipes. The black color on the surface comes from iron oxide. Black steel pipes can be galvanized or painted to achieve anti-corrosion purposes. They are often used to transport natural gas, although some individuals also use them for water transportation. However, it's not recommended for water transport because black steel pipes are prone to rusting in humid environments, and iron filings can contaminate drinking water, posing health risks.Black steel pipe can be either seamless or welded, depending on the production method. You can obtain high-quality steel pipes from black steel pipe manufacturers, such as Nansteel Manufacturing Co., Ltd., based on your project requirements.

2.ASTM A53/A53M Black Steel Pipe

ASTM A53/A53M is a common black steel pipe specification, covering seamless and welded black and hot-dipped galvanized steel pipes from NPS 1/8 to NPS 26.(1)Chemical Composition

Carbon ≤ 0.30%Manganese ≤ 1.20%

Phosphorus ≤ 0.05%

Sulfur ≤ 0.045%

Chromium ≤ 0.40%

Nickel ≤ 0.40%

Copper ≤ 0.40%

These chemical composition restrictions ensure the strength, toughness, and corrosion resistance of the pipeline.

(2)Mechanical Properties

The mechanical properties of a material refer to its ability to resist cracking and excessive deformation under external forces. The tensile strength is ≥ 330MPa, and the yield strength is ≥ 205MPa. Additionally, the elongation of the pipe also has specific requirements to ensure it is not prone to breakage or deformation during use.(3)Appearance Quality

ASTM A53/A53M standards require that the surface of black steel pipes be smooth and free from obvious oxidation, cracks, and defects. Steel pipe manufacturers can enhance the corrosion resistance, wear resistance, and aging resistance of the pipe through surface treatment. Common surface treatment methods for black steel pipes include mechanical methods (shot blasting, grinding, rust removal), chemical methods (pickling, alkali washing, electrolytic polishing, and solution heat treatment), and paint protection.(4)Wall Thickness

In industrial pipelines, schedule 40 and schedule 80 black pipes are more common. Schedule (sch) represents the standard pipe wall thickness, with 40 representing the specified value of wall thickness (in centimeters). Pipes of different standards and materials have varying wall thicknesses corresponding to sch40.

Previous:Mild steel erw pipe