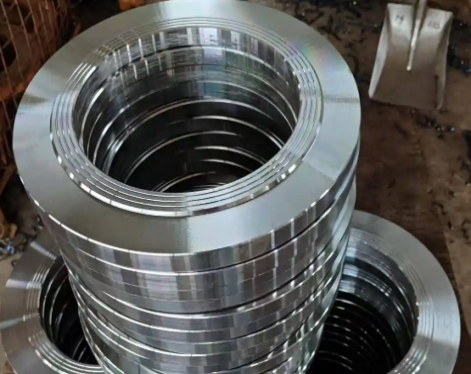

The thickness of a stainless steel flange is not only the physical foundation supporting the piping system, but also the first line of defense against media leakage. Flanges that are too thin are prone to deformation under high pressure, leading to seal failure, while overly thick flanges result in unnecessary material costs and economic burden.

Flanges form a tight connection with opposing flanges through bolts and gaskets, and their thickness directly determines the connection strength and sealing performance. The appropriate thickness allows the flange to withstand internal pipe pressure, temperature fluctuations, and external loads, ensuring the long-term stable operation of the system.

Depending on the application scenario, flange thickness is subject to strict standard specifications. These standards are based on the accumulated experience of engineering practice and are technical regulations that guarantee industrial safety and production.

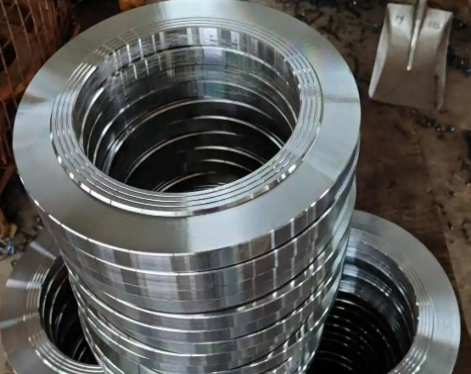

Pressure Requirements: High-pressure environments require thicker flanges to ensure secure and safe connections. For example, a DN50 flange with a PN10 rating has a thickness of approximately 20mm, while a flange of the same specification with a PN16 rating has a thickness increased to 24mm.

Temperature Conditions: In high-temperature environments, material thermal expansion and strength changes must be considered, and an appropriate thickness must be selected to ensure the stability of the flange at high temperatures.

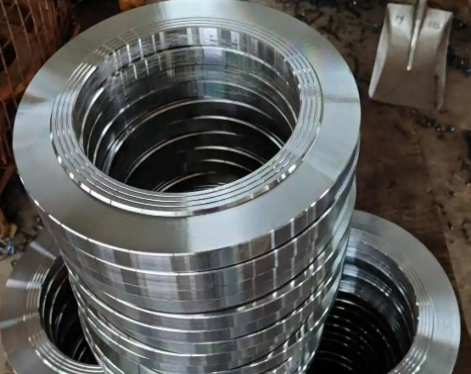

Medium Characteristics: When conveying corrosive media, thicker flanges (especially those made of corrosion-resistant materials such as stainless steel) are required to ensure that the connection is not affected by corrosion and to extend its service life. Different flange types also have different thickness standards. According to national standards, ordinary flanges, high-pressure flanges, and wear-resistant flanges each have corresponding thickness specifications.

Taking a DN50 stainless steel flange as an example, the thickness of a raised-face flange with a PN10 rating is typically 20mm, while the thickness for a PN16 rating increases to 24mm. For a DN100 flange, the PN10 thickness is approximately 22mm, the PN16 thickness is approximately 26mm, and the PN25 thickness may reach 30mm or more.

Flanges in high-pressure environments require greater thickness to withstand internal pressure and prevent deformation and leakage. For example, high-pressure flanges generally have a thickness greater than 20mm, with common thicknesses being 22mm or thicker.

Wear-resistant flanges are used in applications requiring resistance to significant wear, such as piping systems conveying granular media, and their thickness is usually around 20mm.

Chinese national standard flanges (GB/T) are the preferred choice for domestic engineering projects, with GB/T 9112-2010 "Integral Steel Pipe Flanges" as the core standard. For example, a DN50 flange has an outer diameter of 60mm, 4 bolt holes, and a bolt circle diameter of 100mm, with a tolerance control within ±0.5mm.

American standard flanges (ANSI) are classified by Class ratings, such as Class 150 corresponding to the Chinese national standard PN2.0MPa, with units in inches. The dimensions of a DN200 (8-inch) flange are slightly larger than the Chinese national standard; unit conversion should be considered during procurement.

European standard flanges (EN) have a dimension system similar to the Chinese national standard, but with more detailed pressure ratings (e.g., PN10/PN16/PN25), suitable for European piping systems, and requiring higher precision in bolt hole distribution (within ±1mm).

In actual engineering projects, domestic projects should prioritize the use of GB/T standards, which offer better compatibility with valves and pipes, stricter tolerance control, and reduced installation errors.

In summary, the thickness standard of stainless steel flanges is a complex and important issue. It is influenced by various factors, including the type of stainless steel material, flange specifications, operating temperature, impact strength, and the type of fluid being handled. When selecting and using stainless steel flanges, these factors should be fully considered, and adjustments should be made based on the specific operating environment and conditions. It is also important to choose reputable manufacturers and high-quality products to ensure that the flange's quality and performance meet the requirements. (Editor: admin)

Flanges form a tight connection with opposing flanges through bolts and gaskets, and their thickness directly determines the connection strength and sealing performance. The appropriate thickness allows the flange to withstand internal pipe pressure, temperature fluctuations, and external loads, ensuring the long-term stable operation of the system.

Depending on the application scenario, flange thickness is subject to strict standard specifications. These standards are based on the accumulated experience of engineering practice and are technical regulations that guarantee industrial safety and production.

Main Factors Determining Flange Thickness Standards

The nominal pressure rating is the core factor determining flange thickness. National standards classify flange pressure ratings into multiple levels, such as PN10, PN16, and PN25, corresponding to working pressures of 1.0 MPa, 1.6 MPa, and 2.5 MPa, respectively.Pressure Requirements: High-pressure environments require thicker flanges to ensure secure and safe connections. For example, a DN50 flange with a PN10 rating has a thickness of approximately 20mm, while a flange of the same specification with a PN16 rating has a thickness increased to 24mm.

Temperature Conditions: In high-temperature environments, material thermal expansion and strength changes must be considered, and an appropriate thickness must be selected to ensure the stability of the flange at high temperatures.

Medium Characteristics: When conveying corrosive media, thicker flanges (especially those made of corrosion-resistant materials such as stainless steel) are required to ensure that the connection is not affected by corrosion and to extend its service life. Different flange types also have different thickness standards. According to national standards, ordinary flanges, high-pressure flanges, and wear-resistant flanges each have corresponding thickness specifications.

Thickness Requirements Under Different Pressure Ratings

The thickness of stainless steel flanges is closely related to their pressure rating. As the pressure rating increases, the flange thickness also increases accordingly.Taking a DN50 stainless steel flange as an example, the thickness of a raised-face flange with a PN10 rating is typically 20mm, while the thickness for a PN16 rating increases to 24mm. For a DN100 flange, the PN10 thickness is approximately 22mm, the PN16 thickness is approximately 26mm, and the PN25 thickness may reach 30mm or more.

Flanges in high-pressure environments require greater thickness to withstand internal pressure and prevent deformation and leakage. For example, high-pressure flanges generally have a thickness greater than 20mm, with common thicknesses being 22mm or thicker.

Wear-resistant flanges are used in applications requiring resistance to significant wear, such as piping systems conveying granular media, and their thickness is usually around 20mm.

Comparison of Thickness Standards in Different Countries

Different countries and regions have established their own standard systems for stainless steel flange thickness. Chinese national standards (GB), American standards (ANSI), and European standards (EN) have certain differences in thickness specifications.Chinese national standard flanges (GB/T) are the preferred choice for domestic engineering projects, with GB/T 9112-2010 "Integral Steel Pipe Flanges" as the core standard. For example, a DN50 flange has an outer diameter of 60mm, 4 bolt holes, and a bolt circle diameter of 100mm, with a tolerance control within ±0.5mm.

American standard flanges (ANSI) are classified by Class ratings, such as Class 150 corresponding to the Chinese national standard PN2.0MPa, with units in inches. The dimensions of a DN200 (8-inch) flange are slightly larger than the Chinese national standard; unit conversion should be considered during procurement.

European standard flanges (EN) have a dimension system similar to the Chinese national standard, but with more detailed pressure ratings (e.g., PN10/PN16/PN25), suitable for European piping systems, and requiring higher precision in bolt hole distribution (within ±1mm).

In actual engineering projects, domestic projects should prioritize the use of GB/T standards, which offer better compatibility with valves and pipes, stricter tolerance control, and reduced installation errors.

In summary, the thickness standard of stainless steel flanges is a complex and important issue. It is influenced by various factors, including the type of stainless steel material, flange specifications, operating temperature, impact strength, and the type of fluid being handled. When selecting and using stainless steel flanges, these factors should be fully considered, and adjustments should be made based on the specific operating environment and conditions. It is also important to choose reputable manufacturers and high-quality products to ensure that the flange's quality and performance meet the requirements. (Editor: admin)