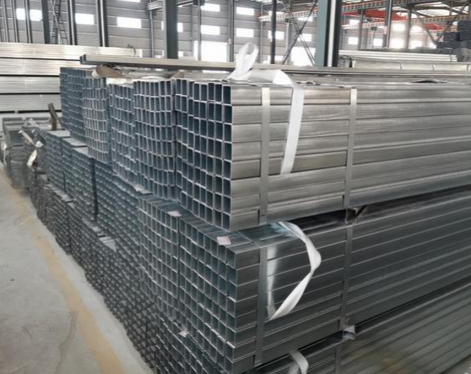

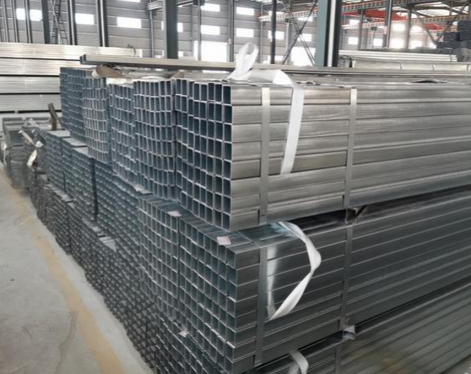

Both hot-rolled and cold-drawn hollow sections are forming processes for seamless square and rectangular tubes. Analyzing them in terms of performance and price, cold-drawn square and rectangular tubes are superior to hot-rolled ones.Cold drawn hollow sections are typically produced from seamless tubes, while hot rolled hollow sections are usually formed from welded pipes, with seamless options used only in special applications.

Hot-rolled hollow sections are manufactured by repeatedly heating and rolling a tube blank. Tubes processed using this method are called hot-rolled tubes.

The R-angle in hollow sections refers to the transitional arc at the connection of two planes. It is generally the radius of the center line of the curved arc. The value of the curved arc R is usually 1.5 to 2.0 times the tube diameter. The size of the R-angle is determined by the wall thickness of the square and rectangular tube. The R-angle is divided into inner R-angle and outer R-angle. The inner R-angle is generally 1.5 to 2 times the wall thickness, and square steel tubes with different R-angles can also be produced according to customer requirements.

For example: For a rectangular steel tube with a rounded corner R, A = 1.0 MM, diagonal = 1.15 MM, how to determine the R-angle? If it is a square steel tube with rounded corners, is the calculation method the same? For a rectangle with length A, width B, diagonal C, and equal corner radii R, the formula for finding R is as follows: (C/2-R)^2=(A/2-R)^2+(B/2-R)^2 C^2/4-CR+R^2=A^2/4-AR+R^2+B^2/4-BR+R^2 4R^2-4(A+B-C)R+(A^2+B^2-C^2)=0 The quadratic formula can be used to find R.

It should be emphasized here that the R-angle of the square and rectangular tube does not refer to the arc, but the central angle. An arc is a segment on the circumference of a circle, and the angle between the lines connecting the two ends of the arc to the center of the circle is the central angle. Since the circumference of a circle is 2πR, and the corresponding central angle is 2π, the arc length corresponding to a unit central angle is 2πR/2π=R. Therefore, the arc length corresponding to any central angle a (in radians) is aR. Methods and tools for measuring the R-angle of square and rectangular tubes include R-gauges and projectors. R-gauges can be used for rough measurements, projectors for more precise measurements, and coordinate measuring machines for even higher accuracy requirements. Cold-drawn square and rectangular tubes are produced through further processing of hot-rolled tubes. Hot-rolled tubes serve as the raw material for this secondary processing. The processing method involves reducing the diameter of the steel tube using a die, pulling the tube through the die with a pulling force. This process does not require heating, hence the term "cold drawing." The purpose of cold drawing is to reduce the diameter of the steel tube. Because the hot-rolling process cannot produce tubes with very small diameters due to its limitations, very thin tubes can only be produced through cold drawing, such as tubes with a diameter of less than 60mm.

Hot-rolled hollow sections are produced by piercing. During production, only the outer diameter of the tube can be controlled. Therefore, the wall thickness of the tube has variations, meaning that during piercing, it is impossible to perfectly pierce the tube blank exactly in the center. Even a slight deviation will result in uneven wall thickness.

Cold-drawn hollow sections, due to the additional processing step, have a more uniform wall thickness compared to hot-rolled tubes. The wall thickness variation is smaller, but it still exists because the raw tubes used for cold drawing already have some wall thickness variations.

Hot-rolled hollow sections are manufactured by repeatedly heating and rolling a tube blank. Tubes processed using this method are called hot-rolled tubes.

The R-angle in hollow sections refers to the transitional arc at the connection of two planes. It is generally the radius of the center line of the curved arc. The value of the curved arc R is usually 1.5 to 2.0 times the tube diameter. The size of the R-angle is determined by the wall thickness of the square and rectangular tube. The R-angle is divided into inner R-angle and outer R-angle. The inner R-angle is generally 1.5 to 2 times the wall thickness, and square steel tubes with different R-angles can also be produced according to customer requirements.

For example: For a rectangular steel tube with a rounded corner R, A = 1.0 MM, diagonal = 1.15 MM, how to determine the R-angle? If it is a square steel tube with rounded corners, is the calculation method the same? For a rectangle with length A, width B, diagonal C, and equal corner radii R, the formula for finding R is as follows: (C/2-R)^2=(A/2-R)^2+(B/2-R)^2 C^2/4-CR+R^2=A^2/4-AR+R^2+B^2/4-BR+R^2 4R^2-4(A+B-C)R+(A^2+B^2-C^2)=0 The quadratic formula can be used to find R.

It should be emphasized here that the R-angle of the square and rectangular tube does not refer to the arc, but the central angle. An arc is a segment on the circumference of a circle, and the angle between the lines connecting the two ends of the arc to the center of the circle is the central angle. Since the circumference of a circle is 2πR, and the corresponding central angle is 2π, the arc length corresponding to a unit central angle is 2πR/2π=R. Therefore, the arc length corresponding to any central angle a (in radians) is aR. Methods and tools for measuring the R-angle of square and rectangular tubes include R-gauges and projectors. R-gauges can be used for rough measurements, projectors for more precise measurements, and coordinate measuring machines for even higher accuracy requirements. Cold-drawn square and rectangular tubes are produced through further processing of hot-rolled tubes. Hot-rolled tubes serve as the raw material for this secondary processing. The processing method involves reducing the diameter of the steel tube using a die, pulling the tube through the die with a pulling force. This process does not require heating, hence the term "cold drawing." The purpose of cold drawing is to reduce the diameter of the steel tube. Because the hot-rolling process cannot produce tubes with very small diameters due to its limitations, very thin tubes can only be produced through cold drawing, such as tubes with a diameter of less than 60mm.

Hot-rolled hollow sections are produced by piercing. During production, only the outer diameter of the tube can be controlled. Therefore, the wall thickness of the tube has variations, meaning that during piercing, it is impossible to perfectly pierce the tube blank exactly in the center. Even a slight deviation will result in uneven wall thickness.

Cold-drawn hollow sections, due to the additional processing step, have a more uniform wall thickness compared to hot-rolled tubes. The wall thickness variation is smaller, but it still exists because the raw tubes used for cold drawing already have some wall thickness variations.