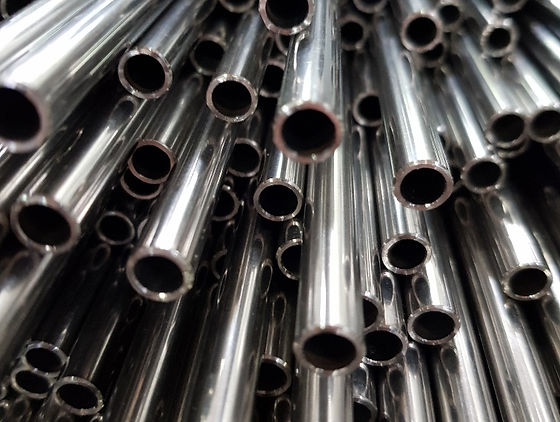

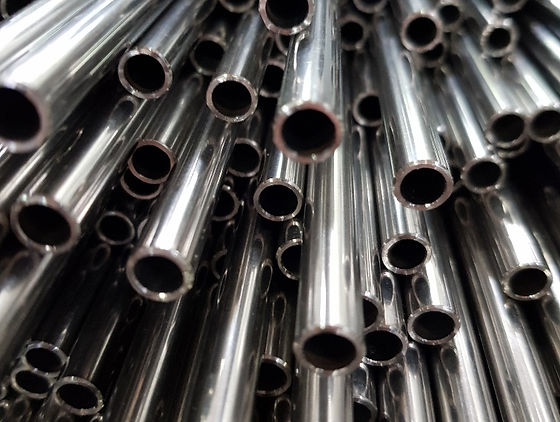

Stainless steel pipes can be divided into many varieties, such as stainless steel seamless pipes, stainless welded steel pipes, stainless steel capillary pipes, etc. Stainless steel pipe has the advantages of corrosion resistance and high temperature resistance, which determines its wide application in industry. For example, stainless steel pipes are used in the chemical and petroleum industries.

Sometimes, stainless steel seamless pipes used in factories may have grease on them. These greases may affect the sealing performance of seamless pipes. Therefore, many factories will choose different methods for degreasing.

The purpose of degreasing stainless steel seamless pipes

Stainless steel pipes for the chemical and petroleum industries are degreased according to special requirements. The purpose of degreasing is to avoid handling of degreased or stored materials in situations where oils or organic materials could cause an explosion, and to avoid mixing of stored oils and organic materials. In order to ensure the activity of the degreasing catalyst, the content of grease can also be controlled. In addition, degreasing controls the oil and organic matter content to ensure the purity of the product. No matter how many advantages stainless steel pipes have, the installed stainless steel pipes must be degreased section by section. If the stainless steel pipe cannot be disassembled, it should be degreased before installation. Stainless steel pipes with obvious oil stains or serious corrosion should be cleaned by steam blowing, sandblasting or other methods before degreasing.

Degreasing solvent

When choosing a degreasing solvent, the following factors should be considered:

1. Degreasing effect: The degreasing solvent should have a good degreasing effect and be able to completely remove grease and stains on the surface of the steel pipe.

2. Environmental protection: The degreasing solvent should have good environmental protection, contain no harmful substances, and be harmless to the human body and the environment.

3. Safety: The degreasing solvent should have good safety and be non-flammable, explosive and corrosive.

Stainless steel pipes can be skimmed using organic solvents (dichloroethylene, trichlorethylene, solvents, benzene, carbon tetrachloride, industrial alcohol, acetone, etc.), concentrated nitric acid or alkali liquid. Industrial dichloroethane is suitable for metal degreasing. Industrial carbon tetrachloride is suitable for degreasing ferrous metal and non-metallic parts. Trichlorethylene is suitable for degreasing metal and non-ferrous metal parts, and 88% concentrated nitric acid is suitable for degreasing pipe parts and ceramic rings of concentrated nitric acid equipment.

When the outer surface of the stainless steel pipe is covered with dirt, the dirt should be removed with water and allowed to dry naturally. Then wipe it with a dry cloth dampened with degreaser and let dry. When degreasing stainless steel pipes, you can tightly plug one end of the pipe with a cork or use other methods to close it. Place the stainless steel pipe in a flat, clean place with sleepers or a workbench and soak it for 60-80 minutes. Rotate it every 20 minutes. Valves, gaskets and other accessories should also be pickled separately and degreased.

Sometimes, stainless steel seamless pipes used in factories may have grease on them. These greases may affect the sealing performance of seamless pipes. Therefore, many factories will choose different methods for degreasing.

The purpose of degreasing stainless steel seamless pipes

Stainless steel pipes for the chemical and petroleum industries are degreased according to special requirements. The purpose of degreasing is to avoid handling of degreased or stored materials in situations where oils or organic materials could cause an explosion, and to avoid mixing of stored oils and organic materials. In order to ensure the activity of the degreasing catalyst, the content of grease can also be controlled. In addition, degreasing controls the oil and organic matter content to ensure the purity of the product. No matter how many advantages stainless steel pipes have, the installed stainless steel pipes must be degreased section by section. If the stainless steel pipe cannot be disassembled, it should be degreased before installation. Stainless steel pipes with obvious oil stains or serious corrosion should be cleaned by steam blowing, sandblasting or other methods before degreasing.

Degreasing solvent

When choosing a degreasing solvent, the following factors should be considered:

1. Degreasing effect: The degreasing solvent should have a good degreasing effect and be able to completely remove grease and stains on the surface of the steel pipe.

2. Environmental protection: The degreasing solvent should have good environmental protection, contain no harmful substances, and be harmless to the human body and the environment.

3. Safety: The degreasing solvent should have good safety and be non-flammable, explosive and corrosive.

Stainless steel pipes can be skimmed using organic solvents (dichloroethylene, trichlorethylene, solvents, benzene, carbon tetrachloride, industrial alcohol, acetone, etc.), concentrated nitric acid or alkali liquid. Industrial dichloroethane is suitable for metal degreasing. Industrial carbon tetrachloride is suitable for degreasing ferrous metal and non-metallic parts. Trichlorethylene is suitable for degreasing metal and non-ferrous metal parts, and 88% concentrated nitric acid is suitable for degreasing pipe parts and ceramic rings of concentrated nitric acid equipment.

When the outer surface of the stainless steel pipe is covered with dirt, the dirt should be removed with water and allowed to dry naturally. Then wipe it with a dry cloth dampened with degreaser and let dry. When degreasing stainless steel pipes, you can tightly plug one end of the pipe with a cork or use other methods to close it. Place the stainless steel pipe in a flat, clean place with sleepers or a workbench and soak it for 60-80 minutes. Rotate it every 20 minutes. Valves, gaskets and other accessories should also be pickled separately and degreased.