Although both OCTG Pipe and Line Pipe are commonly used steel pipes in the energy sector, they differ significantly in definition, performance, structure, and other dimensions due to different application scenarios and functional requirements. The specific differences can be compared from the following five core dimensions:

Core definitions and application scenarios

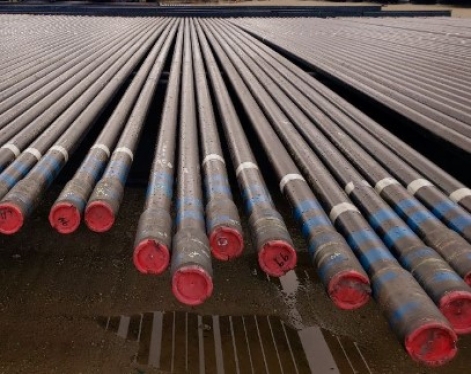

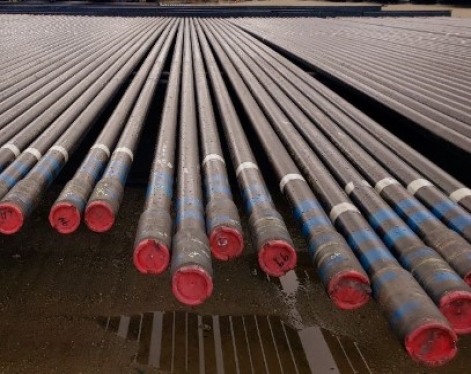

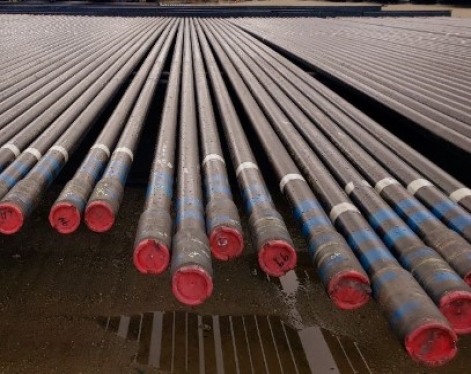

OCTG Pipe (Oil Country Tubular Goods): The full name is "Oil Country Tubular Goods" (OCTG Pipe), which is a steel pipe directly used in the oil and gas well production process, equivalent to the "skeleton and channel" of the oil and gas well. Application scenarios cover the entire process of drilling, cementing, completion, and oil/gas production, specifically including drill pipe (transmitting drilling power), casing pipe (reinforcing the well wall to prevent collapse), and oil pipe (transporting underground oil and gas to the surface), and must face the complex working conditions of high pressure, high temperature, and corrosion underground.

Line Pipe: A steel pipe mainly used for long-distance transportation of fluid media such as oil, natural gas, refined oil, and water. It is the core component of the energy "transportation channel". Application scenarios are concentrated in long-distance onshore pipelines, submarine oil/gas pipelines, urban gas, water supply and drainage pipelines, etc., which need to adapt to long-distance, low-pressure fluctuation transportation environments.

Differences in performance requirements

Pressure level

1. OCTG pipe: Need to withstand downhole high pressure (up to 30MPa or more), emphasizing high pressure resistance to prevent the fluid in the well from breaking through the pipe body

2. Line pipe: Need to adapt to long-distance transmission pressure (usually 10-15MPa), focus on pressure stability, and avoid leakage risks during long-distance transportation

Corrosion resistance

1. OCTG pipe: Need to resist downhole acidic fluids (H₂S, CO₂) and salt water corrosion, need to use sulfur-resistant steel (such as N80Q), special coatings, and some need to resist hydrogen-induced cracking (HIC) performance

2. Line pipe: Focus on soil corrosion (onshore) and seawater corrosion (undersea), and often use external anti-corrosion layers (such as 3PE) to improve corrosion resistance

Mechanical strength

1. OCTG pipe: Emphasis on high strength and fatigue resistance (drill pipe needs to withstand drilling torque repeatedly, and casing pipe needs to resist formation compression), higher strength grade (such as casing P110, drill pipe S135)

2. Line pipe: Emphasis on toughness and weldability (long-distance pipelines require a lot of welding), moderate strength grade (such as API 5L B, X65)

Low temperature performance

Product structure and specifications

OCTG Pipe (Oil-Terrain Tubular Goods): Primarily seamless pipe (with a few welded pipes used for low-pressure wells), it requires special fittings (such as API trapezoidal threads for casing and through-hole fittings for drill pipe) for quick connection and sealing. OCTG pipes are typically 9-13 meters in length (to accommodate derrick height) and have a relatively small diameter (typically 4-13¾ inches for casing and 2-4½ inches for tubing). Some products (such as drill pipe) require thickening of the pipe body to enhance wear resistance.

Line Pipe: Mostly straight seam welded (ERW) or spiral welded (SSAW) pipe, with a few high-pressure pipelines using seamless pipe. Line Pipes are typically 6-12 meters in length (for long-distance installation) and come in a wide range of diameters (from DN100 to DN2000+, with large diameters being the main focus). They have relatively uniform wall surfaces and require no complex joints, requiring only weld grooves at both ends.

Implementation standards and certification

OCTG Pipe (Oil Well Tubing): OCTG pipe complies with specialized standards such as API 5CT (casing/tubing) and API 5D (drill pipe). In addition to basic mechanical properties, testing is also required for thread accuracy, sealing performance (such as airtightness testing), and corrosion resistance (such as NACE TM0177). Some high-end products require user-specific certification (such as supplier qualification review by CNPC and Sinopec).

Line Pipe: The core implementation standard is API 5L (American Petroleum Institute standard) or GB/T 9711 (Chinese national standard). The focus is on chemical composition, tensile strength, impact toughness, welding quality and anti-corrosion layer performance. Certification is mainly based on standard compliance testing.

Read more: Types of OCTG Pipe

Core definitions and application scenarios

OCTG Pipe (Oil Country Tubular Goods): The full name is "Oil Country Tubular Goods" (OCTG Pipe), which is a steel pipe directly used in the oil and gas well production process, equivalent to the "skeleton and channel" of the oil and gas well. Application scenarios cover the entire process of drilling, cementing, completion, and oil/gas production, specifically including drill pipe (transmitting drilling power), casing pipe (reinforcing the well wall to prevent collapse), and oil pipe (transporting underground oil and gas to the surface), and must face the complex working conditions of high pressure, high temperature, and corrosion underground.

Line Pipe: A steel pipe mainly used for long-distance transportation of fluid media such as oil, natural gas, refined oil, and water. It is the core component of the energy "transportation channel". Application scenarios are concentrated in long-distance onshore pipelines, submarine oil/gas pipelines, urban gas, water supply and drainage pipelines, etc., which need to adapt to long-distance, low-pressure fluctuation transportation environments.

Differences in performance requirements

Pressure level

1. OCTG pipe: Need to withstand downhole high pressure (up to 30MPa or more), emphasizing high pressure resistance to prevent the fluid in the well from breaking through the pipe body

2. Line pipe: Need to adapt to long-distance transmission pressure (usually 10-15MPa), focus on pressure stability, and avoid leakage risks during long-distance transportation

Corrosion resistance

1. OCTG pipe: Need to resist downhole acidic fluids (H₂S, CO₂) and salt water corrosion, need to use sulfur-resistant steel (such as N80Q), special coatings, and some need to resist hydrogen-induced cracking (HIC) performance

2. Line pipe: Focus on soil corrosion (onshore) and seawater corrosion (undersea), and often use external anti-corrosion layers (such as 3PE) to improve corrosion resistance

Mechanical strength

1. OCTG pipe: Emphasis on high strength and fatigue resistance (drill pipe needs to withstand drilling torque repeatedly, and casing pipe needs to resist formation compression), higher strength grade (such as casing P110, drill pipe S135)

2. Line pipe: Emphasis on toughness and weldability (long-distance pipelines require a lot of welding), moderate strength grade (such as API 5L B, X65)

Low temperature performance

1. OCTG pipe: Except for polar wells, the requirements for low-temperature performance are relatively low, and more attention is paid to high-temperature stability (downhole temperatures can reach over 150°C)

2. Line pipe: Pipelines in cold regions must have low-temperature toughness (e.g., impact energy at -40°C must meet standards) to prevent low-temperature cracking.

Product structure and specifications

OCTG Pipe (Oil-Terrain Tubular Goods): Primarily seamless pipe (with a few welded pipes used for low-pressure wells), it requires special fittings (such as API trapezoidal threads for casing and through-hole fittings for drill pipe) for quick connection and sealing. OCTG pipes are typically 9-13 meters in length (to accommodate derrick height) and have a relatively small diameter (typically 4-13¾ inches for casing and 2-4½ inches for tubing). Some products (such as drill pipe) require thickening of the pipe body to enhance wear resistance.

Line Pipe: Mostly straight seam welded (ERW) or spiral welded (SSAW) pipe, with a few high-pressure pipelines using seamless pipe. Line Pipes are typically 6-12 meters in length (for long-distance installation) and come in a wide range of diameters (from DN100 to DN2000+, with large diameters being the main focus). They have relatively uniform wall surfaces and require no complex joints, requiring only weld grooves at both ends.

Implementation standards and certification

OCTG Pipe (Oil Well Tubing): OCTG pipe complies with specialized standards such as API 5CT (casing/tubing) and API 5D (drill pipe). In addition to basic mechanical properties, testing is also required for thread accuracy, sealing performance (such as airtightness testing), and corrosion resistance (such as NACE TM0177). Some high-end products require user-specific certification (such as supplier qualification review by CNPC and Sinopec).

Line Pipe: The core implementation standard is API 5L (American Petroleum Institute standard) or GB/T 9711 (Chinese national standard). The focus is on chemical composition, tensile strength, impact toughness, welding quality and anti-corrosion layer performance. Certification is mainly based on standard compliance testing.

Read more: Types of OCTG Pipe