Carbon steel plates, as a fundamental material in modern industry, occupy an irreplaceable position in the automotive manufacturing sector due to their excellent mechanical properties, processability, and cost-effectiveness. From body structures to chassis components, from exterior panels to structural parts, the application of carbon steel plates permeates every aspect of automobile manufacturing. With the continuous improvement of requirements for vehicle lightweighting, safety, and environmental protection, carbon steel material technology is also constantly evolving, providing a solid material foundation for the development of the automotive industry.In addition to carbon steel plates, the types of steel pipes commonly used in automobile manufacturing mainly include seamless steel pipes, welded steel pipes, galvanized steel pipes, and stainless steel pipes. Different types of steel pipes have specific applications in different parts of the automobile.

Specific Applications in Automotive Parts

1. Body PanelsExterior body panels (such as doors, hoods, trunk lids, fenders, etc.) mainly use deep-drawing low-carbon steel sheets (such as DC01, DC04 series). These materials have excellent deep-drawing performance and surface quality, meeting the forming requirements of complex curved surfaces while ensuring good surface coating effects. Typically, 0.6-1.2mm thick cold-rolled steel sheets are used, and after surface treatments such as electrophoresis and spraying, they exhibit good corrosion resistance.

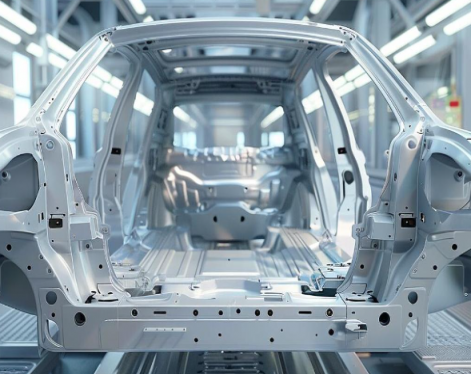

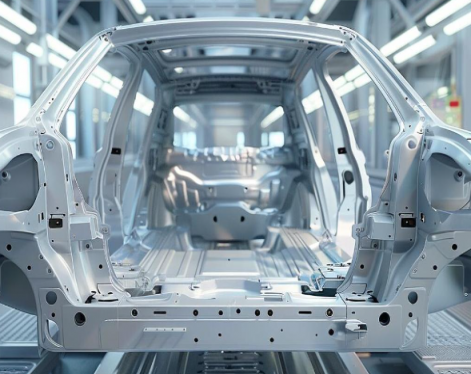

2. Body Structural Components

Body frame structural components (such as A/B/C pillars, sill beams, longitudinal beams, crossbeams, etc.) require high strength and rigidity, and mainly use high-strength steel and ultra-high-strength steel. According to different strength grades, they can be divided into:

High-strength steel (HSS): Yield strength 210-550MPa, used for general load-bearing structural components.

Ultra-high-strength steel (UHSS): Yield strength above 550MPa, used for critical energy absorption zones and anti-collision structures.

Hot-formed steel: Through hot stamping process, the strength can reach over 1500MPa, used for critical safety structures such as A-pillars and B-pillars.

These materials, while ensuring safety performance, achieve lightweighting by reducing thickness, meeting collision safety regulations.

3. Chassis System Components

The chassis system includes the suspension system, braking system, and steering system, which require strict requirements for material fatigue strength, wear resistance, and dimensional stability. Main applications include:

Suspension system: Control arms, stabilizer bars, etc., use medium-carbon steel or low-alloy steel, which are heat-treated to obtain good overall mechanical properties.

Braking system: Brake discs, brake drums, etc., use wear-resistant cast iron or carbon steel, requiring good thermal stability and wear resistance.

Steering system: Steering knuckles, tie rods, etc., use forged medium-carbon steel parts to ensure strength and fatigue life.

4. Engine and Transmission System

Engine mounts, gearbox housings, driveshafts, and other components need to withstand vibration and impact loads, and mostly use medium-carbon steel or low-alloy steel. Rotating components such as drive shafts require high dynamic balancing accuracy and therefore use seamless or welded steel pipes that undergo precision machining and heat treatment.

5. Other Functional Components

These include seat frames, seat belt anchor points, and fuel tank brackets. Different strength grades of carbon steel plates are selected according to functional requirements. Seat frames often use high-strength steel stampings to achieve lightweight design while maintaining strength; seat belt anchor points use ultra-high-strength steel to ensure safety during collisions.

From a vehicle's entire lifecycle perspective, although a significant portion of greenhouse gas emissions comes from the combustion of gasoline and diesel fuel during use, the emissions generated during the vehicle manufacturing phase cannot be ignored. As the global automotive industry accelerates its transition to electrification and power grids gradually become more low-carbon, greenhouse gas emissions from vehicle manufacturing will become increasingly prominent. Carbon steel, as the most widely used material in vehicle manufacturing (by weight), is used in the frame, body, engine, transmission, and drivetrain systems. Currently, the steel industry is one of the most energy-intensive and carbon-intensive industries globally, and the production of primary steel still relies heavily on fossil fuels, particularly coal. To achieve climate targets, it is necessary to explore cleaner and lower-carbon production methods for steel used in vehicle manufacturing.