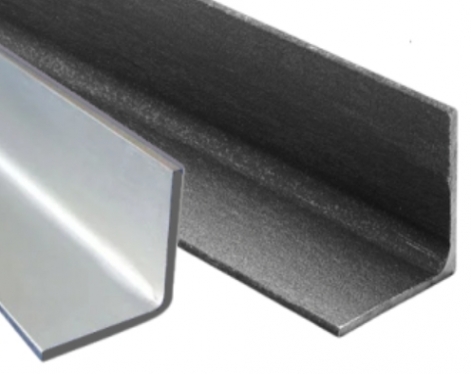

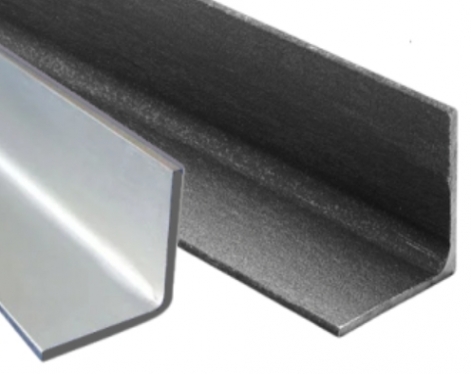

Angle steel, commonly known as angle iron, is a long strip of steel with two sides perpendicular to each other at right angles. It is an economical section steel and is widely used in industrial and civil construction. Depending on whether the two sides are equal in length, they are divided into equal-leg angle steels and unequal-leg angle steels. The specifications are expressed in millimeters of side width × side width × side thickness, such as "∠30×30×3", which means an equal-leg angle steel with a side width of 30 mm and a side thickness of 3 mm.

Its materials include carbon steel, stainless steel, alloy steel, etc. Carbon steel angle steel has low cost and strong versatility; stainless steel angle steel has good corrosion resistance; alloy steel angle steel can meet special performance requirements. Angle steel can be combined with other components through welding, bolting, etc., and is often used in frame support of building structures, bridge truss construction, frame structure of machinery manufacturing, and the production of transmission towers, shelves and other facilities.

What are the material testing methods for angle steel?

1. Chemical composition analysis

Spectral analysis: Spectroscopic analysis is used to analyze the composition of angle steel and accurately determine the element content in angle steel, such as carbon, manganese, silicon, chromium, nickel, sulfur, etc. This method has a high degree of accuracy and reliability and is an important basis for judging the quality of angle steel materials.

2. Mechanical property test

Tensile test: Test the mechanical property indicators such as tensile strength, yield point, elongation after fracture of angle steel to uate its ability to withstand tension.

Impact test: uate the toughness and brittleness of angle steel when subjected to impact load, including high and low temperature impact tests and multiple impact tests.

Hardness test: Use a hardness tester to measure the hardness value of angle steel, including Rockwell hardness, Brinell hardness, Vickers hardness, Leeb hardness and Webster hardness, etc., to understand its ability to resist local deformation.

3. Metallographic inspection

Metallographic microscope observation: Use a metallographic microscope to observe the microstructure and organization of the angle steel, including decarburization layer, grain size, non-metallic inclusions, and chemical composition segregation. This helps to uate the mechanical properties, corrosion resistance, and service life of the angle steel.

4. Nondestructive testing

Acoustic testing: Use the characteristics of sound waves propagating in materials to detect defects inside angle steel, such as cracks, inclusions, etc. This method has the advantages of simple operation, fast detection speed, and no damage to materials.

X-ray testing: X-rays are used to detect angle steel to detect its internal defects and structural integrity. X-ray testing has high accuracy in detecting tiny defects inside angle steel.

Magnetic particle testing: A magnetic field is applied to the surface of the angle steel, and then magnetic particles are sprinkled on its surface to detect defects through the position where the magnetic particles are adsorbed. This method is mainly used to detect defects such as cracks and pores on the surface of angle steel.

5. Other tests

Appearance test: Observe the surface condition of the angle steel with the naked eye or a magnifying glass to determine whether there are cracks, deformation, corrosion and other defects.

Dimension measurement: Use tools such as vernier calipers and angle rulers to measure the length, width, thickness and angle of the angle steel to ensure that it meets the design requirements.

In summary, there are many methods for material testing of angle steel, which should be comprehensively considered and selected according to specific needs and purposes. In practical applications, a variety of testing methods can be used in combination to fully uate the quality and performance of angle steel.

Read more: Surface Treatment Method of Angle Steel

Its materials include carbon steel, stainless steel, alloy steel, etc. Carbon steel angle steel has low cost and strong versatility; stainless steel angle steel has good corrosion resistance; alloy steel angle steel can meet special performance requirements. Angle steel can be combined with other components through welding, bolting, etc., and is often used in frame support of building structures, bridge truss construction, frame structure of machinery manufacturing, and the production of transmission towers, shelves and other facilities.

What are the material testing methods for angle steel?

1. Chemical composition analysis

Spectral analysis: Spectroscopic analysis is used to analyze the composition of angle steel and accurately determine the element content in angle steel, such as carbon, manganese, silicon, chromium, nickel, sulfur, etc. This method has a high degree of accuracy and reliability and is an important basis for judging the quality of angle steel materials.

2. Mechanical property test

Tensile test: Test the mechanical property indicators such as tensile strength, yield point, elongation after fracture of angle steel to uate its ability to withstand tension.

Impact test: uate the toughness and brittleness of angle steel when subjected to impact load, including high and low temperature impact tests and multiple impact tests.

Hardness test: Use a hardness tester to measure the hardness value of angle steel, including Rockwell hardness, Brinell hardness, Vickers hardness, Leeb hardness and Webster hardness, etc., to understand its ability to resist local deformation.

3. Metallographic inspection

Metallographic microscope observation: Use a metallographic microscope to observe the microstructure and organization of the angle steel, including decarburization layer, grain size, non-metallic inclusions, and chemical composition segregation. This helps to uate the mechanical properties, corrosion resistance, and service life of the angle steel.

4. Nondestructive testing

Acoustic testing: Use the characteristics of sound waves propagating in materials to detect defects inside angle steel, such as cracks, inclusions, etc. This method has the advantages of simple operation, fast detection speed, and no damage to materials.

X-ray testing: X-rays are used to detect angle steel to detect its internal defects and structural integrity. X-ray testing has high accuracy in detecting tiny defects inside angle steel.

Magnetic particle testing: A magnetic field is applied to the surface of the angle steel, and then magnetic particles are sprinkled on its surface to detect defects through the position where the magnetic particles are adsorbed. This method is mainly used to detect defects such as cracks and pores on the surface of angle steel.

5. Other tests

Appearance test: Observe the surface condition of the angle steel with the naked eye or a magnifying glass to determine whether there are cracks, deformation, corrosion and other defects.

Dimension measurement: Use tools such as vernier calipers and angle rulers to measure the length, width, thickness and angle of the angle steel to ensure that it meets the design requirements.

In summary, there are many methods for material testing of angle steel, which should be comprehensively considered and selected according to specific needs and purposes. In practical applications, a variety of testing methods can be used in combination to fully uate the quality and performance of angle steel.

Read more: Surface Treatment Method of Angle Steel