To put it simply, low-alloy seamless pipe is actually a stainless steel plate made of aluminum alloy. It is a long steel plate with a hollow cross-section and no seams around it.

Read more

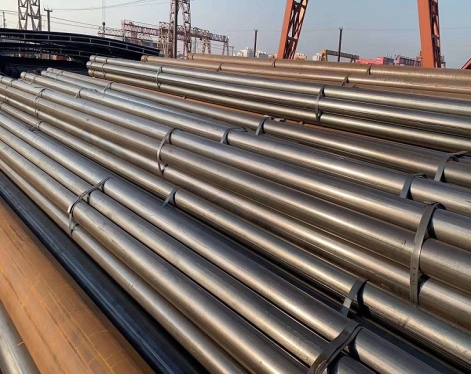

Seamless steel pipes are made of a whole round steel perforated. Steel pipes with no welds on the surface are called seamless steel pipes.

Read more

The material selection and construction requirements of tunnel seamless steel pipes are important links in ensuring the stability and safety of tunnel projects.

Read more

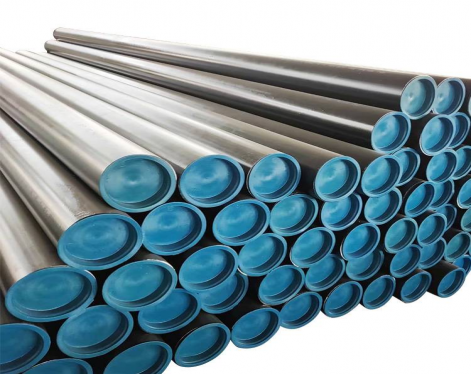

Fluid seamless pipe is a pipe used to transport fluid. Its inner wall is smooth and seamless, which can ensure smooth flow of fluid.

Read more

The quality hazards of seamless steel pipes cannot be ignored.

Read more

There are many common types of seamless steel pipes on the market, and medium and low temperature pressure seamless steel pipes are one of the important varieties.

Read more